PRODUCT CATALOGUE

Emirates Preinsulated Pipes Ind.

Abu Dhabi, United Arab Emirates

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

WARRANTY

EPPI will warrant and guarantee materials in accordance with

specifications, as well as its workmanship, to be free of defects.

Any claim for apparent defects must be made within 30 (thirty)

days after delivery or before installation, whichever occurs first.

Later defects - material which proves defective within one year

after shipment - will be replaced or repaired provided the

materials have been properly installed, operated and have not

been damaged by neglect or abuse. EPPI SHALL NOT be

liable for consequential damages, and liability is expressly

limited to repair or replacement of materials F.O.B. our factory.

All the information and recommendations contained in this product catalogue are subject to change without prior notice.

All Rights Reserved 2011

Printed in the United Arab Emirates

INTRODUCTION

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

We would like to take this opportunity to introduce ourselves to you. We are Emirates

Preinsulated Pipes Industries (EPPI); engineers and manufacturers of thermally insulated

piping systems for chilled & hot water, steam, gas, and other energy related applications.

EPPI was established in the year 2000 in response to the needs of the local market. We

are a sister company of Saudi Preinsulated Pipes Industries (SPPI) operating since 1983,

and we bring with us years of experience in this field. Our production started early 2002.

Our new manufacturing facility is located in Industrial City of Abu Dhabi (ICAD-1) at

Mussafah and it is equipped to handle all steel pipe fabrication processes including

cutting, threading, grooving, and welding technologies by certified technicians according

to international standards. All welding processes will undergo non-destructive testing

along with the required in-house and third-party test programs.

EPPI offers complete steel pipe protection services prior to insulation, such as, shot/grit

blasting on internal & external surfaces. Airless spray epoxy coating is applied per the

project’s specification.

We are equipped with the latest technology in polyurethane (PUR) foam dispensing and

processing techniques to ensure the quality of the factory-applied insulation. Our

insulation processing is among the foremost in the region to be 100% CFC-free, which

supports the elimination of ozone-depleting potential with ZERO-ODP. Our extrusion

technology is state-of-the-art with fully-automated processes to produce seamless and

solid-wall high density polyethylene (HDPE) pipe profile.

EPPI provides quality products, piping system stress analysis capability, incorporation of

leak detection and surveillance system, on-site technical assistance and installation

supervision whenever needed. Our Quality Management system is an ISO-9001 certified

throughout the entire manufacturing processes.

TABLE OF CONTENTS

1.0.0 Product’s Technical Data

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

EPPI Standard Product

1.1.0 Rigid Preinsulated Piping System

1.1.1 Core Pipe and Core Fitting

1.1.1.1 Steel Pipe Specification

1.1.1.2 Steel Pipe Dimensions

1.1.1.3 Standard Steel Fittings

1.1.1.3a 90

0

and 45

0

Elbow

1.1.1.3b Equal Tee and Reducing Tee

1.1.1.3c Concentric and Eccentric Reducers

1.1.1.3d Welding Outlet

1.1.2. Insulation

1.1.2.1 100% CFC Free Polyurethane Foam (PUR)

1.1.3. Protective Jacket

1.1.3.1 High-Density Polyethylene (HDPE) Pipe

1.1.3.1a Density and Composition

1.1.3.1b Melt Flow Rate

1.1.3.1c Thermal Stability

1.1.3.1d Long Term Mechanical Properties and Raw Material

1.1.3.1e Use of Rework Material

1.1.3.2 Jacket Pipe Properties

1.1.3.2a Nominal Outside Diameter

1.1.3.2b Wall Thickness

1.1.3.2c Tolerances on Outside diameter and Wall Thickness

1.1.3.2d Appearance, Surface, Finish, Pipe Ends

1.1.3.2e Elongation at Break

1.1.3.3 Weathering Resistance of HDPE

1.2.0 Flexible Preinsulated Piping System

1.2.1 Core Pipe

1.2.2 Insulation

1.2.3 Protective Jacket

1.2.3.1 Outside Diameter

1.2.3.2 Wall Thickness

1.3.0 Accessories

1.3.1 End Seals

1.3.2 Anchors

1.3.3 Wall Entry Sleeves & Link Seals

1.3.4 Expansion Joints

1.4.0 Field Joint Insulation

1.4.1 Joint Preparation

1.4.2 Installation of Rayjoint Sleeve

1.4.3 Pressure Test

1.4.4 Pouring of PUR Foam Chemicals

Other Preinsulated Piping Product

1.5.0 Rigid Preinsulated Piping System for Large Diameters

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

1.6.0 Rigid Preinsulated HDPE Piping System

1.7.0 Rigid Preinsulated Piping System for High Temperature Application

2.0.0 Leak Detection System

2.1.0 Installation Procedure

2.2.0 Insulation Test

2.3.0 Continuity Test

3.0.0 Product Handling Instructions

3.1.0 Unloading

3.2.0 Storage

4.0.0 Engineering Data

4.1.0 Thermal Expansion in Steel Pipe

4.2.0 Pipe Trenches/Backfill

4.3.0 Heat Loss

4.4.0 Conversion Table

5.0.0 EPPI Information

5.1.0 Project References

5.2.0 ISO Certificate

1.1.0 RIGID PREINSULATED PIPING SYSTEM

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

The rigid preinsulated piping system consist of carbon steel as the core pipe with 100% CFC free polyurethane foam

insulation and high density polyethylene (HDPE) as the jacket pipe.

For normal application, the pipe assembly should have a life of at least 30 years at a continuous operating system

temperature of 120 ˚C, at least 50 years at a continuous operating temperature of 115 ˚C and over 50 years at a

continuous operating temperature below 115 ˚C.

Table 1.1.0-A: Series I

Steel Pipe

HDPE Casing

OD

Insulation

Thickness

Overall

Weight

U Value

Nominal Dia.

Inch

OD

mm

mm mm kg/m W/m

2

.

O

K

¾ 26.7 90 28.7 2.8 0.424

1 33.4 110 35.3 4.0 0.351

1 ¼ 42.2 125 38.4 5.2 0.338

1 ½ 48.3 125 35.4 5.8 0.389

2 60.3 140 36.8 7.4 0.393

2 ½ 73.0 168 44.5 11.0 0.328

3 88.9 180 42.6 14.0 0.363

4 114.3 200 39.7 19.0 0.416

5 141.3 220 35.9 25.4 0.485

6 168.3 250 37.0 32.0 0.481

8 219.1 315 43.1 49.2 0.419

10 273.1 355 35.4 67.5 0.534

12 323.9 400 31.8 81.4 0.608

14 355.6 450 40.2 90.5 0.476

16 406.4 500 39.0 105.9 0.497

18 457.2 560 42.6 121.0 0.455

20 508.0 630 51.2 137.6 0.377

Table 1.1.0-B: Series 2

Steel Pipe HDPE Casing Insulation Overall U Value

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Nominal Dia.

Inch

OD

mm

OD Thickness Weight

mm mm kg/m W/m

2

.

O

K

3/4 26.7 110 38.7 3.2 0.293

1 33.4 125 42.8 4.3 0.276

1 ¼ 42.2 125 45.9 5.5 0.271

1 ½ 48.3 140 56.9 6.6 0.216

2 60.3 168 56.8 8.4 0.230

2 ½ 73.0 180 60.3 12.1 0.225

3 88.9 200 62.1 15.3 0.228

4 114.3 220 64.0 20.6 0.234

5 141.3 250 65.0 28.0 0.240

6 168.3 315 68.5 35.7 0.234

8 219.1 355 62.4 51.0 0.274

10 273.1 400 57.2 69.8 0.313

12 323.9 450 56.1 84.2 0.327

14 355.6 500 64.4 95.9 0.283

16 406.4 560 68.0 111.3 0.271

18 457.2 630 76.6 128.1 0.240

20 508.0 630 51.2 137.6 0.377

1.1.1.0 CORE

PIPE

AND

CORE

FITTING

1.1.1.1 Steel Pipe Specifications

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

The steel pipe shall be ERW, SAW or Seamless, conforming to ASTM A53, API 5L or A106, Grades A or B,

wall thickness per requirements (Standard weight, Schedule 40 or Extra Strong). The pipes shall be with

either beveled ends for welded joints or grooved ends for mechanical coupling joints.

Table 1.1.1.0-A: Chemical Requirements

Composition, max. %

Carbon Manganese Phosphorous Sulfur

Type S (Seamless pipe)

Open-hearth, electric-furnace or basic-oxygen:

Grade A

Grade B

0.25

0.30

0.95

1.20

0.05

0.05

0.06

0.06

Type E (Electric-resistance welded pipe)

Open-hearth, electric-furnace or basic-oxygen:

Grade A

Grade B

0.25

0.30

0.95

1.20

0.05

0.05

0.06

0.06

Type F (Furnace-welded pipe)

Open-hearth, electric-furnace or basic-oxygen.

---

---

0.06

0.045

Table 1.1.1.0-B: Limits on Unspecified Elements

Composition, max. %

Copper Nickel Chromium Molybdenum Vanadium

Type S (Seamless pipe)

Open-hearth, electric-

furnace or basic-oxygen:

Grade A

Grade B

0.40

0.40

0.40

0.40

0.40

0.40

0.15

0.15

0.08

0.08

Type E (Electric-resistance-welded pipe)

Open-hearth, electric-

furnace or basic-oxygen:

Grade A

Grade B

0.40

0.40

0.40

0.40

0.40

0.40

0.15

0.15

0.08

0.08

*The combination of these five elements shall not exceed 1.00%

Table 1.1.1.0-C: Tensile Requirements

Type F Type E and S

Open-hearth, electric-furnace or

basic-oxygen.

Grade A

Grade B

Tensile strength, min, psi (mPa) 45,000 (310) 48,000 (330) 60,000 (415)

Yield strength, min, psi (mPa) 25,000 (170) 30,000 (205) 35,000 (240)

Other core pipe materials are also available. Please refer to “Other Preinsulated Piping Product”

section for further details.

1.1.1.2 Steel Pipe Dimensions

In accordance with ANSI B36.1

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Table 1.1.1.0-D

Nominal

Diameter

Outside

Diameter

Standard Weight Schedule 40 Extra Strong

Wall

Thickness

Nominal

Weight

Wall

Thickness

Nominal

Weight

Wall

Thickness

Nominal

Weight

Inch

mm Inch mm Inch mm Lb/ft Kg/m Inch mm Lb/ft Kg/m Inch mm Lb/ft Kg/m

½ 15 0.840 21.3 0.109 2.8 0.85 1.28 0.109 2.8 0.85 1.28 0.147 3.7 1.09 1.61

¾ 20 1.050 26.7 0.113 2.9 1.13 1.70 0.113 2.9 1.13 1.70 0.154 3.9 1.47 2.19

1 25 1.315 33.4 0.133 3.4 1.68 2.52 0.133 3.4 1.68 2.52 0.179 4.5 2.17 3.21

1¼ 32 1.660 42.2 0.140 3.6 2.27 3.43 0.140 3.6 2.27 3.43 0.191 4.9 3.00 4.51

1½ 40 1.900 48.3 0.145 3.7 2.72 4.07 0.145 3.7 2.72 4.07 0.200 5.1 3.63 5.43

2 50 2.375 60.3 0.154 3.9 3.65 5.42 0.154 3.9 3.65 5.42 0.218 5.5 5.02 7.43

2½ 65 2.875 73.0 0.203 5.2 5.79 8.69 0.203 5.2 5.79 8.69 0.276 7.0 7.66 11.39

3 75 3.500 88.9 0.216 5.5 7.58 11.31 0.216 5.5 7.58 11.31 0.300 7.6 10.25 15.24

4 100 4.500 114.3 0.237 6.0 10.79 16.02 0.237 6.0 10.79 16.02 0.337 8.6 14.98 22.42

5 125 5.563 141.3 0.258 6.6 14.62 21.92 0.258 6.6 14.62 21.92 0.375 9.5 20.78 30.88

6 150 6.625 168.3 0.280 7.1 18.97 28.22 0.280 7.1 18.97 28.22 0.432 11.0 28.57 42.67

8 200 8.625 219.1 0.322 8.2 28.55 42.65 0.322 8.2 28.55 42.65 0.500 12.7 43.39 64.64

10 250 10.750 273.1 0.365 9.3 40.48 60.50 0.365 9.3 40.48 60.50 0.500 12.7 54.74 81.55

12 300 12.750 323.9 0.375 9.5 49.56 73.65 0.406 10.3 53.52 79.65 0.500 12.7 65.42 97.46

14 350 14.00 355.6 0.375 9.5 54.57 81.08 0.438 11.1 63.44 94.30 0.500 12.7 72.09 107.4

16 400 16.00 406.4 0.375 9.5 62.58 92.98 0.500 12.7 82.77 123.30 0.500 12.7 82.77 123.3

18 450 18.00 457.2 0.375 9.5 70.59 104.84 0.562 14.3 104.67 156.11 0.500 12.7 93.45 139.2

20 500 20.00 508.0 0.375 9.5 78.60 116.78 0.594 15.1 123.11 183.42 0.500 12.7 104.1 155.1

24 600 24.00 609.6 0.375 9.5 94.62 140.68 0.688 17.5 171.29 255.24 0.500 12.7 125.5 187.1

26 650 26.00 660.4 0.375 9.5 102.63 152.39 0.688 17.5 185.99 277.27 0.500 12.7 136.1 202.7

30 750 30.00 762.0 0.375 9.5 118.65 176.29 0.688 17.5 215.38 321.29 0.500 12.7 157.5 234.7

32 800 32.00 812.8 0.375 9.5 126.66 188.24 0.688 17.5 230.08 343.30 0.500 12.7 168.2 250.6

36 900 36.00 914.4 0.375 9.5 142.68 211.90 0.750 19.1 282.35 421.50 0.500 12.7 189.6 282.3

40 1000 40.00 1016.0 0.375 9.5 158.70 235.79 0.750 19.1 314.39 469.55 0.500 12.7 210.9 314.2

1.1.1.3 Standard Steel Fittings

Conforming to ASTM A234WPB

Dimensions in accordance with ASME B16.9

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

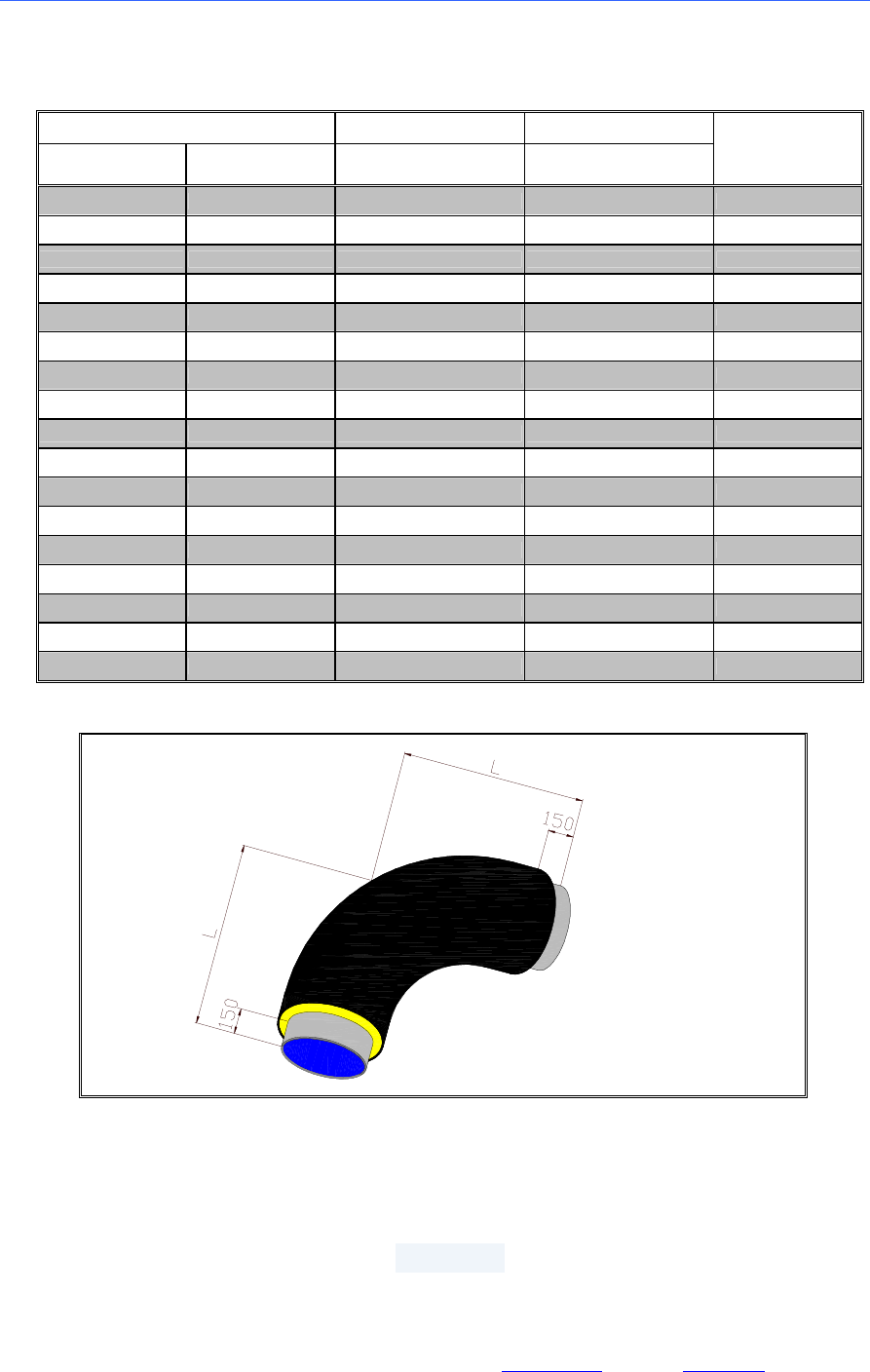

1.1.1.3a 90

0

and 45

0

Elbow

Table 1.1.1.0-E

Nominal

Diameter

Outside

Diameter

at Bevel

D

Center to End

Long Radius Elbow Short Radius Elbow

90º

A

45º

B

90º

A

45º

B

Inch mm Mm mm mm mm

¾ 26.7 28.4 11.2 -- --

1 33.4 38.1 22.4 25.4 --

1¼ 42.2 47.8 25.4 31.8 --

1½ 48.3 57.2 28.4 38.1 --

2 60.3 76.2 35.1 50.8 --

2½ 73.0 95.2 44.4 63.5 --

3 88.9 114.3 50.8 76.2 31.6

4 114.3 152.4 63.5 101.6 42.1

5 141.3 190.5 79.2 127.0 52.6

6 168.3 228.6 95.2 152.4 63.4

8 219.1 304.8 127.0 203.2 84.2

10 273.1 381.0 158.8 254.0 105.2

12 323.9 457.2 190.5 304.8 126.3

14 355.6 533.4 222.2 355.6 147.3

16 406.4 609.6 254.0 406.4 168.3

18 457.2 685.8 285.8 457.2 189.4

20 508.0 762.0 317.5 508.0 210.4

OD OD

A

A

B

B

Nominal

Diameter

Outside

Diameter

at Bevel

D

Center to End

Long Radius Elbow

Short Radius Elbow

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

90º

A

45º

B

90º

A

45º

B

Inch mm Mm mm mm mm

22 558.8 838.2 342.9 558.8 231.5

24 609.6 914.4 381.0 609.6 252.5

26 660.4 990.6 406.4 660.4 273.5

28 711.2 1066.8 438.2 711.2 294.6

30 762.0 1143.0 469.9 762.0 315.6

32 812.8 1219.2 501.6 812.8 378.1

34 863.6 1295.4 533.4 863.6 357.7

36 914.4 1371.6 565.2 914.4 378.8

38 965.2 1447.8 599.9 -- --

40 1016.0 1524.0 632.0 1016.0 420.8

42 1066.8 1600.2 660.4 1066.8 441.9

44 1117.6 1676.4 695.4 1117.6 462.9

46 1168.4 1752.6 726.9 -- --

48 1219.2 1828.8 759.0 1219.2 505.0

52 1320.8 -- -- 1320.8 547.1

54 1371.6 2057.4 852.2 1371.6 568.1

56 1422.4 2133.6 883.8 1422.4 589.2

60 1524.0 2286.0 946.9 1524.0 631.3

66 1676.4 2514.6 1041.6 -- --

72 1828.8 2743.2 1262.5 -- --

80 2032.0 -- -- 2032.0 841.7

OD OD

A

A

B

B

90

0

Elbow

Table 1.1.1.0-F

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

45

0

Elbow

Table 1.1.1.0-G

Steel Pipe Series 1 Series 2

L

mm

Nominal Dia.

Inch

OD

mm

HDPE Casing OD

mm

HDPE Casing OD

mm

¾ 26.7 90 110 328

1 33.4 110 125 338

1¼ 42.2 125 140 348

1½ 48.3 125 168 357

2 60.3 140 180 376

2½ 73.0 168 200 395

3 88.9 180 225 414

4 114.3 200 250 452

5 141.3 225 280 490

6 168.3 250 315 529

8 219.1 315 355 605

10 273.1 355 400 681

12 323.9 400 450 757

14 355.6 450 500 833

16 406.4 500 560 910

18 457.2 560 630 986

20 508.0 630 630 1062

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

1.1.1.3b Equal Tee and Reducing Tee

Table 1.1.1.0-H

Steel Pipe Series 1 Series 2

L

mm

Nominal Dia.

Inch

OD

Mm

HDPE Casing OD

mm

HDPE Casing OD

mm

¾ 26.7 90 110 311

1 33.4 110 125 322

1¼ 42.2 125 140 325

1½ 48.3 125 168 328

2 60.3 140 180 335

2½ 73.0 168 200 344

3 88.9 180 220 351

4 114.3 200 250 364

5 141.3 220 280 379

6 168.3 250 315 395

8 219.1 315 355 427

10 273.1 355 400 459

12 323.9 400 450 491

14 355.6 450 500 522

16 406.4 500 560 554

18 457.2 560 630 586

20 508.0 630 630 618

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Nominal

Pipe Size

(NPS)

Outside Diameter

at Bevel

OD

Center – to – End

Nominal

Pipe Size

(NPS)

Outside Diameter

at Bevel

OD

Center – to – End

Run

C

Outlet

M

Run

C

Outlet

M

Run Outlet Run Outlet

½ X ½ 21.3 21.3 25.4 25.4 5 X 5 141.3 141.3 124.0 124.0

3/8

17.3

25.4

4

114.3

117.3

1/4 13.7 25.4 3 ½ 101.6 114.3

3/4

X 3/4

26.7

26.7

28.4

28.4

3

88.9

111.3

1/2 21.3 28.4 2 ½ 73.0 108.0

3/8

17.3

28.4

2

60.3

104.6

1 X 1 33.4 33.4 38.1 38.1 1 ½ 48.3

¾

26.7

38.1

6 X 6

168.3

168.3

142.7

142.7

½ 21.3 38.1 5 141.3 136.7

1 ¼ X 1 ¼

42.2

42.2

47.8

47.8

4

114.3

130.0

1 33.4 47.8 3 ½ 101.6 127.0

¾

26.7

47.8

3

88.9

124.

0

½ 21.3 47.8 2 ½ 73.0 120.6

1 ½ X 1 ½

48.3

48.3

57.2

57.2

2

60.3

1 ¼ 42.2 57.2 8 X 8 219.1 219.1 177.8 177.8

1

33.4

57.2

6

168.3

168.1

¾

26.7

57.2

5

141.3

162.1

½ 21.3 57.2 4 114.3 155.4

2

X 2

60.3

60.3

63.5

63.5

3 ½

101.6

152.4

1 ½ 48.3 60.5 3 88.9

1 ¼

42.2

57.2

10 X 10

273.1

273.1

215.9

215.9

1 33.4 50.8 8 219.1 203.2

¾

26.7

44.4

6

168

.3

193.5

½ 21.3 5 141.3 190.5

2 ½ X 2 ½

73.0

73.0

76.2

76.2

4

114.3

184.2

2 60.3 69.8 12 X 12 323.9 323.9 254.0 254.0

1 ½

4

8.3

66.5

10

273.1

241.3

1 ¼ 42.2 63.5 8 219.1 228.6

1 33.4 57.2 6 168.3 218.9

3 X 3 88.9 88.9 85.8 85.8 5 141.3 215.9

2 ½

73.0

82.6

14 X 14

355.6

355.6

279.4

279.4

2 60.3 76.2 12 323.9 269.7

1 ½ 48.3 73.2 10 273.1 257.0

1 ¼

4

2.2

69.8

8

219.1

247.6

1 33.4 6 168.3 238.3

3 ½ X 3 ½

101.6

101.6

95.2

95.2

16 X 16

406.4

406.4

304.8

304.8

3 88.9 91.9 14 355.6 304.8

2 ½ 73.0 88.9 12 323.9 295.1

2

60.3

82.6

10

273.1

282.4

1 ½ 48.3 79.2 8 219.1 373.0

4 X 4

114.3

11

4.3

104.6

104.6

6

168.3

263.7

3 ½ 101.6 101.6 18 X 18 457.2 457.2 342.9 342.9

3

88.9

98.6

16

406.4

330.2

2 ½ 73.0 95.2 14 355.6 330.2

2

60.3

88.9

12

323.9

320.5

1 ½

48.3

85.8

10

273.1

307.8

1 ¼ 42.2 8 219.1 298.4

1 ¼ 33.5

CCC C

OD

OD

OD

M

OD

M

Nominal

Pipe Size

(NPS)

Outside Diameter

at Bevel

OD

Outside Diameter

at Bevel

OD

Nominal

Pipe Size

(NPS)

Outside Diameter

at Bevel

OD

Outsid

e Diameter

at Bevel

OD

Run Outlet Run Outlet

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Run Run

C

M

Run Run

C

M

20 X 20 508.0 508.0 381.0 381.0 30 X 12 762.0 323.9 558.8 472.6

18 457.2 368.3 10 273.1 460.2

16

406.4

35

5.6

32 X 32

812.8

812.8

596.9

596.9

14

355.6

355.6

30

762.0

584.2

12 323.9 345.9 28 711.2 571.5

10

273.1

333.2

26

660.4

571.5

8 219.1 323.8 24 609.6 558.8

22 X 22

558.8

558.8

419.1

419.1

22

558.8

546.1

20 508.0 406.4 20 508.0 533.4

18 457.2 393.7 18 457.2 520.7

16

406.4

381.0

16

406.4

508.0

14 355.6 381.0 14 355.6 508.0

12

323.9

371.3

34 X 34

863.6

863.6

635.0

635.0

10 273.1 358.6 32 812.8 622.3

24 X 24

609.6

609.6

431.8

431.8

30

762.0

609.6

22 558.8 431.8 28 711.2 596.9

20 508.0 431.8 26 660.4 596.9

18

457.2

419.1

24

609.6

584.2

16 406.4 406.4 22 558.8 571.5

14

355.

6

406.4

20

508.0

558.8

12 323.9 396.7 18 457.2 546.1

10 273.1 384.0 16 406.4 533.4

26 X 26 660.4 660.4 495.3 495.3 36 X 36 914.4 914.4 673.1 673.1

24 609.6 482.6 34 863.6 660.4

22

558.8

469.9

32

812.8

647.7

20 508.0 457.2 30 762.0 635.0

18 457.2 444.5 28 711.2 622.3

16

406.4

431.8

26

660.4

622.3

14 355.6 431.8 24 609.6 609.6

12

323.9

422.1

22

558.8

596.9

28 X 28 711.2 711.2 520.7 520.7 20 508.0 584.2

26

660.4

520.7

18

457.2

571.5

24 609.6 508.0 16 406.4 558.8

22

558.8

495.3

38 X 38

965.2

965.2

711.2

711.2

20 508.0 482.6 36 914.4 711.2

18 457.2 469.9 34 863.6 698.5

16

406.4

457.2

32

812.8

685.8

14 355.6 457.2 30 762.0 673.1

12 323.9 447.5 28 711.2 647.7

30 X 30 762.0 762.0 558.8 558.8 26 660.4 647.7

28 711.2 546.1 24 609.6 635.0

26

660.4

546.1

22

558.8

622.3

24 609.6 533.4 20 508.0 609.6

22

558.8

520.7

18

457.2

596.9

20 508.0 508.0

18

457.2

495.3

16

406.4

482.6

14

355.6 482.6

NOTE: 1) Outlet dimensions “M” for NPS 26” and larger is recommended but not required.

2) Outlet dimensions “M” for run sizes NPS 14” and larger is recommended but not required.

CCC C

OD

OD

OD

M

OD

M

Nominal

Pipe Size

(NPS)

Outside Diameter

at Bevel

OD

Out

side Diameter

at Bevel

OD

Nominal

Pipe Size

(NPS)

Outside Diameter

at Bevel

OD

Outside Diameter

at Bevel

OD

Run Outlet Run Outlet

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Run Run

C

M

Run Run

C

M

40 X 40 1016.0 1016.0 749.3 749.3 46 X 46 1168.4 1168.4 850.9 800.1

36 914.4 736.6 42 1066.8 787.4

32 812.8 812.8 38

965.2 762.0

28

711.2

673.1

34

863.6

749.3

42 X 42 1066.8 1066.8 762.0 711.2 48 X 48 1219.2 1219.2 889.0 838.2

38

965.2

711.2

44

1117.6

838.2

34 863.6 711.2 40 1016.0 812.8

30 762.0 711.2 36 914.4 787.4

44 X 44 1117.6 1117.6 812.8 762.0 68 X 68 1727.2 1727.2 1219.2 1066.8

40

1016.0

749.3

36 914.4 723.9

32 812.8 711.2

24

609.6

698.5

NOTE: 1) Outlet dimensions “M” for NPS 26” and larger is recommended but not required.

2) Outlet dimensions “M” for run sizes NPS 14” and larger is recommended but not required.

CCC C

OD

OD

OD

M

OD

M

Equal Tee and Reducing Tee

Table 1.1.1.0-I

Core Dimension Core Dimension

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Nominal

Outside Diameter

End to

end

Center to end

Nominal

Outside

Diameter

End to

end

Center to

end

Diameter

Run Branch Run Branch Diameter

Run Branch Run Branch

Inch

mm

mm

C

(mm)

M

(mm)

Inch

mm

mm

C

(mm)

M

(mm)

½ x ½

21.3 21.3 651 325

2½ x 2½

73.0 73.0 752 376

½ x ¼

21.3 13.7 651 325

2½ x 2

73.0 60.3 752 370

¾ x ¾

26.7 26.7 657 328

2½ x 1½

73.0 48.3 752 367

¾ x ½

26.7 21.3 657 328

2½ x 1¼

73.0 42.2 752 364

1 x 1

33.4 33.4 676 338

2½ x 1

73.0 33.4 752 357

1 x ¾

33.4

26.7

676

338

3 x 3

88.9

88.9

772

386

1 x ½

33.4 21.3 676 338

3 x 2½

88.9 73.0 772 383

1¼ x 1¼

42.2 42.2 696 348

3 x 2

88.9 60.3 772 376

1¼ x 1

42.2 33.4 696 348

3 x 1½

88.9 48.3 772 373

1¼ x ¾

42.2 26.7 696 348

3 x 1¼

88.9 42.2 772 370

1¼ x ½

42.2 21.3 696 348

3 x 1

88.9 33.4 772 367

1½ x 1½

48.3 48.3 714 357

4 X 4

114.3 114.3 809 405

1½ x 1¼

48.3 42.2 714 357

4 X 3

114.3 88.9 809 399

1½ x 1

48.3 33.4 714 357

4 x 2½

114.3 73.0 809 395

1½ x ¾

48.3 26.7 714 357

4 x 2

114.3 30.3 809 389

1½ x ½

48.3 21.3 714 357

4 x 1½

114.3 48.3 809 386

2 x 2

60.3

60.3

727

364

5 x 5

141.3

141.3

848

424

2 x 1½

60.3

48.3

727

361

5 x 4

141.3

114.3

848

4

17

2 x 1¼

60.3

42.2

727

357

5 x 3

141.3

88.9

848

411

2 x 1 60.3

33.4

727

351

5 x 2½

141.3

73.0

848

408

2 x ¾

60.3 26.7 727 344

5 x 2 141.3 60.3 848 405

Equal and Reducing Tee

Table 1.1.1.0-J

Core Dimension Core Dimension

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Nominal

Outside

Diameter

End to

end

Center to end

Nominal

Outside

Diameter

End to

end

Center to

end

Diameter

Run Branch

Run Branch Diameter Run Branch

Run Branch

Inch

mm

mm

C

(mm)

M

(mm)

Inch

mm

mm

C

(mm)

M

(mm)

6 x 6 168.3 168.3 885 443 14 x 14 355.6 355.6 1159 579

6 x 5 168.3 141.3 885 437 14 x 12 355.6 323.9 1159 570

6 x 4

168.3

114.3

885

430

14 x 10

355.6

273.1

1159

557

6 x 3

168.3

88.9

885

424

14 x 8

355.6

219.1

1159

548

6 x 2½

168.3

73.0

885

421

14 x 6

355.6

168.3

1159

538

8 x 8 219.1 219.1 956 478 16 x 16 406.4 406.4 1210 605

8 x 6 219.1 168.3 956 468 16 x 14 406.4 355.6 1210 605

8 x 5 219.1 141.3 956 462 16 x 12 406.4 323.9 1210 595

8 x 4 219.1 114.3 956 455 16 x 10 406.4 273.1 1210 582

8 x 3 219.1 88.9 956 452 16 x 8 406.4 219.1 1210 573

10 x 10

273.1

273.1

1032

516

16 x 6

406.4

168.3

1210

564

10 x 8 273.1 219.1 1032 503 18 x 18 457.2 457.2 1286 643

10 x 6 273.1 168.3 1032 494 18 x 16 457.2 406.4 1286 630

10 x 5 273.1 141.3 1032 491 18 x 14 457.2 355.6 1286 630

10 x 4 273.1 114.3 1032 484 18 x 12 457.2 323.9 1286 621

12 x 12 323.9 323.9 1108 554 18 x 10 457.2 273.1 1286 608

12 x 10 323.9 273.1 1108 541 18 x 8 457.2 219.1 1286 598

12 x 8 323.9 219.1 1108 529 20 x 20 508.0 508.0 1362 681

12 x 6 323.9 168.3 1108 519 20 x 18 508.0 457.2 1362 669

12 x 5 323.9 141.3 1108 516 20 x 16 508.0 406.4 1362 656

20 x 14 508.0 355.6 1362 656

20 x 12 508.0 323.9 1362 646

20 x 10 508.0 273.1 1362 633

20 x 8

508.0

219.1

1362

624

Flyover and Reducing Tee

Table 1.1.1.0-K

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

d1

¾

1 1¼

1½

2 2½

3 4 5 6 8 10 12 14 16 18 20

D1

90

110

125

140

168

180

200

220

250

280

315

355

400

450

500

560

630

L1

657

676

696

714

727

752

772

809

848

885

956

1032

1108

1159

1210

1286

1362

d2

D2

L2(mm)

¾

90

339

346

353

360

351

1 110

365

372

379

374

379

1¼

125

377

384

384

388

393

1½

140

389

391

396

400

409

2 168

405

409

414

423

434

2½

180

430

434

443

452

461

3 200

448

456

465

474

4 220

482

491

500

518

539

5 250

523

532

550

570

588

6 280

563

581

599

617

631

649

8 315

643

661

678

692

710

728

746

10

355

724

742

753

771

789

807

12

400

805

816

834

852

870

14

450

877

895

913

931

16

500

949

967

985

18

560

1030

1049

20

630

1111

1.1.1.3c Concentric and Eccentric Reducers

Table 1.1.1.0-L

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Nominal

Diameter

Inch

Outside Diameter

Nominal

Diameter

Inch

Outside Diameter

Large End

mm

Small End

mm

End-to-End

H (mm)

Large End

mm

Small End

mm

End-to-End

H (mm)

¾ x ½ 26.7 21.3 38.1 6 x 3 88.9 139.7

1 x ¾ 26.7 50.8 6 x 2½ 73.0 139.7

1 x ½ 21.3 50.8 8 x 6 219.1 168.3 152.4

1¼ x 1 42.2 33.4 50.8 8 x 5 141.3 152.4

1¼ x ¾ 26.7 50.8 8 x 4 114.3 152.4

1¼ x ½ 21.3 50.8 8 x 3 88.9 152.4

1½ x 1¼ 48.3 42.2 63.5 10 x 8 273.1 219.1 177.8

1½ x 1 33.4 63.5 10 x 6 168.3 177.8

1½ x ¾ 26.7 63.5 10 x 5 141.3 177.8

1½ x ½ 21.3 63.5 10 x 4 114.3 177.8

2 x 1½ 60.3 48.3 76.2 12 x 10 323.9 273.1 203.2

2 x 1¼ 42.2 76.2 12 x 8 219.1 203.2

2 x 1 33.4 76.2 12 x 6 168.3 203.2

2 x ¾ 26.7 76.2 12 x 5 141.3 203.2

2½ x 2 73.0 60.3 88.9 14 x 12 355.6 323.9 330.2

2½ x 1½ 48.3 88.9 14 x 10 273.1 330.2

2½ x 1¼ 42.2 88.9 14 x 8 219.1 330.2

2½ x 1 33.4 88.9 14 x 6 168.3 330.2

3 x 2½ 88.9 73.0 88.9 16 x 14 406.4 355.6 355.6

3 x 2 60.3 88.9 16 x 12 323.9 355.6

3 x 1½ 48.3 88.9 16 x 10 273.1 355.6

3 x 1¼ 42.2 88.9 16 x 8 219.1 355.6

3 x 1 33.4 88.9 18 x 16 457.2 406.4 381.0

4 X 3 114.3 88.9 101.6 18 x 14 355.6 381.0

4 x 2½ 73.0 101.6 18 x 12 323.9 381.0

4 x 2 60.3 101.6 18 x 10 273.1 381.0

4 x 1½ 48.3 101.6 20 x 18 508.0 457.2 508.0

5 x 4 141.3 114.3 127.0 20 x 16 406.4 508.0

5 x 3 88.9 127.0 20 x 14 355.6 508.0

5 x 2½ 73.0 127.0 20 x 12 323.9 508.0

5 x 2 60.3 127.0 20 x 10 273.1 508.0

6 x 5 168.3 141.3 139.7 20 x 8 219.1 508.0

6 x 4 114.3 139.7

NOTE: 1) The shape of Reducer Sizes 16” and larger may be manufactured to conical type without the tangent.

HH

OD

2

OD

1

OD

2

OD

1

Nominal Outside Diameter Nominal Outside Diameter

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Diameter

Inch

Large End

mm

Small End

mm

End-to-End

H (mm)

Diameter

Inch

Large End

mm

Small End

mm

End-to-End

H (mm)

22 x 20 558.8 508.0 508.0 38 x 36 965.2 914.4

609.6

22 x

18

457.2

508.0

38 x 3

4

863.6

609.6

22 x 16

406.4

508.0

38 x 32

812.8

609.6

22 x 14

355.6

508.0

38 x 30

762.0

609.6

24 x 22 609.6 558.8

508.0

38 x 28

711.2

609.6

24 x 20

508.0

508.0

38 x 26

660.4

609.6

24 x 18

457.2

508.0

40 x 38 1016.0 965.2

609.6

24 x 16

406.4

508.0

40 x 36

914.4

609.6

26 x 24 660.4 609.6

609.6

40 x 34

863.6

609.6

26 x 22

558.8

609.6

40 x 32

812.8

609.6

26 x 20

508.0

609.6

40 x 30

762.0

609.6

26 x

18

457.2

609.6

40 x 28 711.2 609.6

28 x 26 711.2 660.4

609.6

42 x 38 1066.8 965.2

609.6

28 x 24

609.6

609.6

42 x 34

863.6

609.6

28 x 20

508.0

609.6

42 x 30

762.0

609.6

28 x

18

457.2

609.6

44 x 40 1117.6 1016.0

609.6

30 x 28 762.0 711.2

609.6

44 x 36

914.4

609.6

30 x 26

660.4

609.6

44 x 32

812.8

609.6

30 x 24

609.6

609.6

46 x 42 1168.4 1066.8

711.2

30 x 20

508.0

609.6

46 x 38

965.2

711.2

32 x 30 812.8 762.0

609.6

46 x 34

863.6

711.2

32 x 28

711.2

609.6

48 x 44 1219.2 1117.6

711.2

32 x 26

660.4

609.6

48 x 40

1016.0

711.2

32 x 24

609.6

609.6

48 x 36

914.4

711.2

34 x 32 863.6 812.8

609.6

52 x 44 1320.8 1117.6

711.2

34 x 30

762.0

609.6

68 x 52 1727.2 1320.8

711.2

34 x 26

660.4

609.6

68 x 44

1117.6

711.2

34 x

24

609.6

609.6

36 x 34 914.4 863.6

609.6

36 x 32

812.8

609.6

36 x 30

762.0

609.6

36 x 26

660.4

609.6

36 x 24

609.6

609.6

NOTE: 1) The shape of Reducer Sizes 16” and larger may be manufactured to conical type without the tangent.

HH

OD2

OD1

OD2

OD1

Reducers

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Table 1.1.1.0-M

Nominal

Diameter

Inch

Reducer

Outside Diameter

Nominal

Diameter

Inch

Reducer

Outside Diameter

Large End

mm

Small End

Mm

With Stubs

H (mm)

Large End

mm

Small End

mm

With Stubs

H (mm)

6 x 3 88.9 740

¾ x ½ 26.7 21.3 638 6 x 2½ 73.0 740

1 x ¾ 26.7 651 8 x 6 219.1 168.3 752

1 x ½ 21.3 651 8 x 5 141.3 752

1¼ x 1 42.2 33.4 651 8 x 4 114.3 752

1¼ x ¾ 26.7 651 8 x 3 88.9 752

1¼ x ½ 21.3 651 10 x 8 273.1 219.1 778

1½ x 1¼ 48.3 42.2 664 10 x 6 168.3 778

1½ x 1 33.4 664 10 x 5 141.3 778

1½ x ¾ 26.7 664 10 x 4 114.3 778

1½ x ½ 21.3 664 12 x 10 323.9 273.1 803

2 x 1½ 60.3 48.3 676 12 x 8 219.1 803

2 x 1¼ 42.2 676 12 x 6 168.3 803

2 x 1 33.4 676 12 x 5 141.3 803

2 x ¾ 26.7 676 14 x 12 355.6 323.9 930

2½ x 2 73.0 60.3 689 14 x 10 273.1 930

2½ x 1½ 48.3 689 14 x 8 219.1 930

2½ x 1¼ 42.2 689 14 x 6 168.3 930

2½ x 1 33.4 689 16 x 14 406.4 355.6 956

3 x 2½ 88.9 73.0 689 16 x 12 323.9 956

3 x 2 60.3 689 16 x 10 273.1 956

3 x 1½ 48.3 689 16 x 8 219.1 956

3 x 1¼ 42.2 689 16 x 6 168.3 956

3 x 1 33.4 689 18 x 16 457.2 406.4 981

4 X 3 114.3 88.9 702 18 x 14 355.6 981

4 x 2½ 73.0 702 18 x 12 323.9 981

4 x 2 30.3 702 18 x 10 273.1 981

4 x 1½ 48.3 702 18 x 8 219.1 981

5 x 4 141.3 114.3 727 20 x 18 508.0 457.2 1108

5 x 3 88.9 727 20 x 16 406.4 1108

5 x 2½ 73.0 727 20 x 14 355.6 1108

5 x 2 60.3 727 20 x 12 323.9 1108

6 x 5 168.3 141.3 740 20 x 10 273.1 1108

6 x 4 114.3 740 20 x 8 219.1 1108

1.1.1.3d Welding Outlet

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Table 1.1.1.0-N

Outlet

Nom’l.

Size

A

C L D Weight in Kg.

STD XS

XXS

S160

STD XS

XXS

S160

STD XS

XXS

S160

STD XS

XXS

S160

1/8 10.3 15.9 15.9 - 15.9 15.9 - 25.4 25.4 - 0.04 0.05 -

1/4 13.7 15.9 15.9 - 15.9 15.9 - 25.4 25.4 - 0.04 0.05 -

3/8 17.1 19.1 19.1 - 19.1 19.1 - 31.8 31.8 - 0.07 0.07 -

1/2 21.3 23.8 23.8 14.3 19.1 19.1 28.6 34.9 34.9 34.9 0.08 0.09 0.11

3/4 26.7 30.2 30.2 19.1 22.2 22.2 31.8 44.5 44.5 44.5 0.11 0.14 0.32

1 33.4 36.5 36.5 25.4 27.0 27.0 38.1 54.0 54.0 50.8 0.23 0.21 0.38

1 ¼ 42.2 44.5 44.5 33.3 31.8 31.8 44.5 65.1 65.1 61.9 0.36 0.41 0.57

1 ½ 48.3 50.8 50.8 38.1 33.3 33.3 50.8 73.0 73.0 69.9 0.45 0.50 0.79

2 60.3 65.1 65.1 42.9 38.1 38.1 55.6 88.9 88.9 81.0 0.79 0.79 0.97

2 ½ 73.0 76.2 76.2 54.0 41.3 41.3 61.9 103.2 103.2 96.8 1.13 1.18 1.53

3 88.9 93.7 93.7 73.0 44.5 44.5 73.0 122.2 122.2 120.7 1.81 1.86 2.87

3 ½ 101.6 101.6 101.6 - 47.6 47.6 - 136.5 136.5 - 2.49 2.54 -

4 114.3 120.7 120.7 98.4 50.8 50.8 84.1 152.4 152.4 152.4 2.86 2.90 4.76

5 141.3 141.3 141.3 122.2 57.2 57.2 93.7 179.4 179.4 187.3 4.65 4.72 6.46

6 168.3 169.9 169.9 146.1 60.3 77.8 104.8 215.9 225.4 220.7 5.44 10.43 12.70

8 219.1 220.7 220.7 - 69.9 98.4 - 263.5 292.1 - 10.43 16.78 -

10 273.1 274.6 265.1 - 77.8 93.7 - 322.3 323.9 - 16.33 20.98 -

12 323.9 325.4 317.5 - 85.7 103.2 - 377.8 379.4 - 26.80 28.00 -

14 355.6 357.2 350.9 - 88.9 100.0 - 409.6 431.8 - 30.00 32.00 -

16 406.4 408.0 403.2 - 93.7 106.4 - 463.6 466.7 - 34.00 46.50 -

18 457.2 458.8 455.6 - 96.8 111.1 - 520.7 523.9 - 44.00 59.00 -

20 508.8 508.0 509.6 - 101.6 119.1 - 571.5 582.6 - 53.50 72.00 -

24 609.6 614.4 614.4 - 115.9 139.7 - 689.0 708.0 - 99.80 131.50 -

NOTE: End preparation shall be in accordance with ASME B16.25.

1.1.2.0 INSULATION

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

1.1.2.1

Polyurethane Foam (PUR)

The insulation shall be rigid cellular 100% CFC free polyurethane foam, factory applied between the core

pipe and the jacket, having a density* of 48 kg/m³ (3.0 lbs/ft³) nominal and a thermal conductivity

coefficient (λ) of 0.028 W/(m•K) or 0.20 BTU•in/(hr•ft²•°F) maximum at a mean temperature of 24 °C (75

°F). The insulation shall meet ASTM specifications C518 with typical operating temperatures between 0° C

to +100° C.

Table 1.1.2.0-A

Physical Properties

Density

ASTM D1622

Compressive Strength

@10% deformation parallel to rise

ASTM D1621

Thermal Conductivity (λ)

@75° F mean temperature, initial

ASTM C518, max.

Dimensional Stability

ASTM D2126, max.

70 ± 2° C, 97 ±3% RH, 168 ±2h

-20 ± 3° C, AMB•RH, 168 ±2h

Water Vapor Permeability

ASTM E96 @ 75 °F max.

Closed Cell Content

ASTM D2856, min.

Water Absorption

ASTM D2842, max.

Values

35 – 65 kg/m³

(2.2 – 4.0 lbs/ft³)

276 – 414 kPa

(40-60 psi)

0.028 W/(m•K)

(0.2 BTU•in/(hr•ft²•°F)

± 5.0 % vol. change

± 3.0 % vol. change

1.2 perm-in

90% by vol.

1.2% by vol.

For fire retardant polyisocyanurate (PIR) foam insulation

:

Surface burning characteristics –

ASTM E84, max.

Flame Spread Index (FSI): ≤25

Smoke Development (SD): ≤500

*Other densities are also available

.

1.1.3.0 PROTECTIVE

JACKET

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

1.1.3.1 High-Density Polyethylene (HDPE) Pipe

The outer casing/protective jacket shall be made of extruded High-Density Polyethylene (HDPE) pipe,

having a material classification of III C5-W8 weather-resistant black, according to ASTM D1248.

Table 1.1.3.0-A

Material Properties

Density

ASTM D792

Melt flow rate, 190° C/2.16 kg. (max)

ASTM D1238

Carbon black content (min)

ASTM D1603

Induction time @200° C (min)

ASTM D3350 (thermal stability)

Vicat softening temperature (min)

ASTM D1525

Brittleness temperature (max)

ASTM D746

ESCR, condition B, f50 (min)

ASTM D1693

Flexural modulus @2% strain (min)

ASTM D790

Tensile strength (min)

ASTM D638

Impact strength, notched (min)

ASTM D256

Rockwell hardness (min)

ASTM D785

Extruded Pipe Properties

Density (± 10)

ASTM D792

Melt flow rate 190° C/ 2.16 kg. (± 0.05)

ASTM D1238

Tensile strength (± 4)

ASTM D638

Elongation at break (± 200)

ASTM D638

Hydrostatic design basis @ 4MPa/80° C (min)

ASTM D2837

Values

941 - 959 kg/m³

(0.941-0.959 g/cm³)

0.4 g/10-min

2%, weight

20 min.

125° C

-55° C

192 h

758 MPa (109 ksi)

21 MPa (3.0 ksi)

105 J/m (2.0 ft. lb-f/in)

60 shore

950 kg/m³

0.15 g/10-min

25 mPa

600%, length

1000 h

1.1.3.1a Density and Composition

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

When tested in accordance with 5.2.1, the base material from which the casing pipe is produced shall be PE

of a density not less than 935 Kg/m³ to which shall be added only those anti-oxidants, UV stabilizers and

carbon black, necessary for the manufacture and end-use of pipes to this specification.

The carbon black added shall comply with the following specifications:

Density 1500 - 2000 kg/m³

Toluene extract ≤ 0.1% by mass

Average particle size 0.01 µm to 0,025 µm

The pipe material shall be black colored PE with a carbon black content of 2.5 ± 0.5% by mass and of a

density not less than 944 kg/m³.

1.1.3.1b Melt Flow Rate

To facilitate welding, the manufacturer shall quote the MFR of the PE pipe, determined in accordance with

ISO 1133, condition 18. The melt flow rate of pipes to be welded shall not differ more than 0.5 g/10 min.

1.1.3.1c Thermal Stability

The induction of time of the pipe material shall be at least 20 min. when tested at 200 °C according to

ISO/TR 10837.

1.1.3.1d Long Term Mechanical Properties and Raw Material

The raw material to be used for the production of casing pipes shall meet the requirements of Table 2 when

tested with internal pressure in accordance with 5.2.5.

A brittle failure is conclusive.

If a sample on the 165 h test fails in less than 165 h and the failure mode is ductile, then a retest shall be

performed, using the 1000 h parameters.

Table 1.1.3.0-B: Mechanical Properties

Circumferential

S

tress

Minimum time

to bursting

Test temperature

°C

4,6

4,0

165

1000

80

80

1.1.3.1e Use of Rework Material

The use of rework material shall be limited to 15% by weight.

Only clean rework-material, generated from the manufacturer’s own production of pipes, shall be used.

1.1.3.2 Jacket Pipe Properties

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

1.1.3.2a Nominal Outside Diameter

Prior to foaming, the nominal outside diameter of the casing pipe should be selected from Table 1.1.3.0-C

1.1.3.2b Wall Thickness

Prior to foaming, the minimum wall thickness of the casing pipe shall be in accordance with Table

1.3.0-C.

Table 1.1.3.0-C: Jacket Dimensions

(Based on EN 253)

Diameter group

Nominal outside diameter, D

mm

Minimum wall thickness

mm

1

75

90

110

125

140

160

180

200

3.0

3.0

3.0

3.0

3.0

3.0

3.0

3.2

2

225

250

280

315

355

400

3.4

3.6

3.9

4.1

4.5

4.8

3

450

500

560

630

730

800

5.2

5.6

6.0

6.6

7.2

7.9

4

900

1000

1100

1200

8.7

9.4

10.2

11.0

1.1.3.2c Tolerances on Outside Diameter and Wall Thickness

Prior to foaming, the tolerances on outside diameter and wall thickness of the extruded PE pipes shall be as

follows: (Derived from EN 253).

The outside diameter shall at any point be between the minimum diameter D

min

and the maximum diameter

D

max

as given in Table 7a of EN 253.

The minimum wall thickness, e

min

shall at any point be on accordance with Table 7a of EN 253.

The measured values fro the outside diameter and wall thickness shall be rounded off to the next higher 0.1

mm.

1.1.3.2d Appearance, Surface Finish, Pipe Ends

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

The internal and external surfaces

4)

of the casing pipe shall be clean and free from such grooving or other

defects that might impair its functional properties (see 5.2.3).

The pipe ends shall be cleanly cut and shall be square within 2.5° with the axis of the pipe.

1.1.3.2e Elongation at Break

Before foaming, the elongation at break determined in accordance with 5.2.7 shall not be less than 350%.

1.1.3.3 Weathering Resistance of HDPE

Like most natural materials and other plastics, on prolonged outdoor exposure, polyethylene is degraded by

weathering, particularly by the combined effect of short-wave ultra-violet rays from sunlight and atmospheric

oxygen.

EPPI HDPE pipes are protected from these effects by the addition of carbon black. Furthermore,

stabilizers such as aromatic amines or phenol derivatives are added to the material to counter any possible

heat aging.

Because carbon black is the most effective protection against UV, EPPI HDPE pipes are normally supplied

in black. This to ensure that black pipes made from this material can be stored or used outdoors over a long

period of time without any fear of a change in properties.

4)

Surface treatment to improve the shear strength between the PUR foam and casing pipe is permissible provided that the treated pipe still complies with the

specification.

1.2.0 FLEXIBLE PREINSULATED PIPING SYSTEM

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

The Flexible Preinsulated Piping System is supplied complete with core pipe, thermal insulation and outer jacket

manufactured as an integrated system, and is supplied in a coil.

Table 1.2.0-A

Type

HDPE Core Pipe

Corrugates LDPE Jacket

Pipe

Insulation

Thickness

Overall Weight

OD (d)

Thickness (s)

SDR 11

OD (D)

Thickness (s1)

mm mm mm mm

mm kg/m

20 / 78 20 1.9 78 2.0 27.0 0.801

25 / 78

25

2.3

78

2

.0

24.5

0.85

32 / 78 32 2.9 78 2.0 21.0 0.932

40 / 93

40

3.7

93

2

.

2

24.3

1.315

50 / 113 50 4.6 113 2.4 29.1 1.88

63 / 128

63

5.8

128

2

.

7

29.8

2.571

75 / 143 75 6.8 143 3.0 31.0 3.329

90 / 163 90 8.2 163 3.2 33.3 4.404

110 / 163

110

10.0

163

3

.

2

23.3

5.235

HDPE CORE PIPE

CFC-FREE FLEXIBLE PUR FOAM

CORONA-TREATED LDPE FILM

CORRUGATED LDPE JACKET PIPE

1.2.1 C

ORE

P

IPE

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

The High Density Polyethylene (HDPE) Core Pipe shall conform to one or more of the following: Specifications

ASTM: D 2104, D 2239, D 3035, F 714 ; DIN: 8075 or 8074 : ISO 4427

1.2.2 I

NSULATION

Thermal Insulation shall have density of 60 kg/m3 (3.75 lbs/ft3) and a maximum thermal conductivity of 0.20 BTU-

in/h-ft

2

-˚F (0.028 W/(m-K) when measured in accordance with Test Method C 177.

All seams of the insulation shall be sealed.

Insulation shall be visually inspected for voids and other defects prior to the application of the jacket. Any voids or

variance in thickness greater than 0.1 in. shall be reason for rejection.

Insulation shall not be bonded to the core pipe.

1.2.3 P

ROTECTIVE

J

ACKET

The Protective Jacket shall be constructed of a watertight corrugated material. It shall contain 2% carbon black,

finely divided and thoroughly dispersed to provide protection from UV degradation.

1.2.3.1 Outside Diameter

The corrugated jacket diameter shall be determined by measuring the outside diameter of the corrugation in

accordance with Table 1.2.3.0-A

1.2.3.2 Wall Thickness

The corrugated jacket thickness shall be based on the diameter of the jacket in accordance with Table

1.2.3.0-A

Table 1.2.3.0-A

(Based on ASTM F 2165)

Outside Diameter Minimum Thickness

in mm in mm

Up to 2.5 inclusive Up to 63 0.040 1.00

Over 2.5 to 3.5 inclusive 63 - 90 0.045 1.10

Over 3.5 to 5.0 inclusive

90

-

128

0.050

1.20

Over 5.0 to 6.3 inclusive 128 - 160 0.070 1.80

Over 6.3 to 7.9 inclusive 160 - 200 0.085 2.10

HEAT LOSS

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Table 1.2.3.0 -B

Heat losses in EPPI – Flex

Flex Pipe

Dimensions

Core W.T.

SDR 11

( mm )

Core

Inside

Φ

( mm )

Core

Outside

Φ

( mm )

Jacket

Corrugation

( mm )

Jacket

Outside

Φ

( mm )

U

( W /m²

O

K )

Q

( Heat Loss

@ ∆T 30

O

C )

( W / m

2

)

20 / 78 1.9 16.2 20 5 78 0.414 12.407

25 / 78 2.3 20.4 25 5 78 0.505 15.135

32 / 78 2.9 26.2 32 5 78 0.666 19.994

40 / 93 3.7 32.6 40 5 93 0.578 17.325

50 / 113 4.6 40.8 50 5 113 0.481 14.419

63 / 128 5.8 51.4 63 5 128 0.488 14.630

75 / 143 6.8 61.4 75 5 143 0.478 14.331

90 / 163 8.2 73.6 90 5 163 0.452 13.560

110 / 163 10 90 110 5 163 0.717 21.511

K-factor of HDPE Core (K

C

) = 0.43 W/m

O

K

K-factor of PU Foam (K

F

) = 0.02 W/m

O

K

K-factor of HDPE Jacket (K

J

) = 0.02 W/m

O

K

1

U = -----------------------------------------------------

r

jo

[ln (r

co

/r

ci

)] + r

jo

[ln (r

ji

/r

co

)] + r

j

[ln (r

jo

/r

ji

)]

----------------- ----------------- ---------------

K

C

K

F

K

J

Q = U∆T

Where:

Q = Heat Loss (

W /m² )

U = Heat Transfer Coefficient (

W /m²

O

K )

r

jo

= HDPE Jacket Outside Diameter (meter)

r

ji

= HDPE Jacket Inside Diameter (meter)

r

co

= HDPE Core Outside Diameter (meter)

r

ci

= HDPE Core Inside Diameter (meter)

1.3.0 ACCESSORIES

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

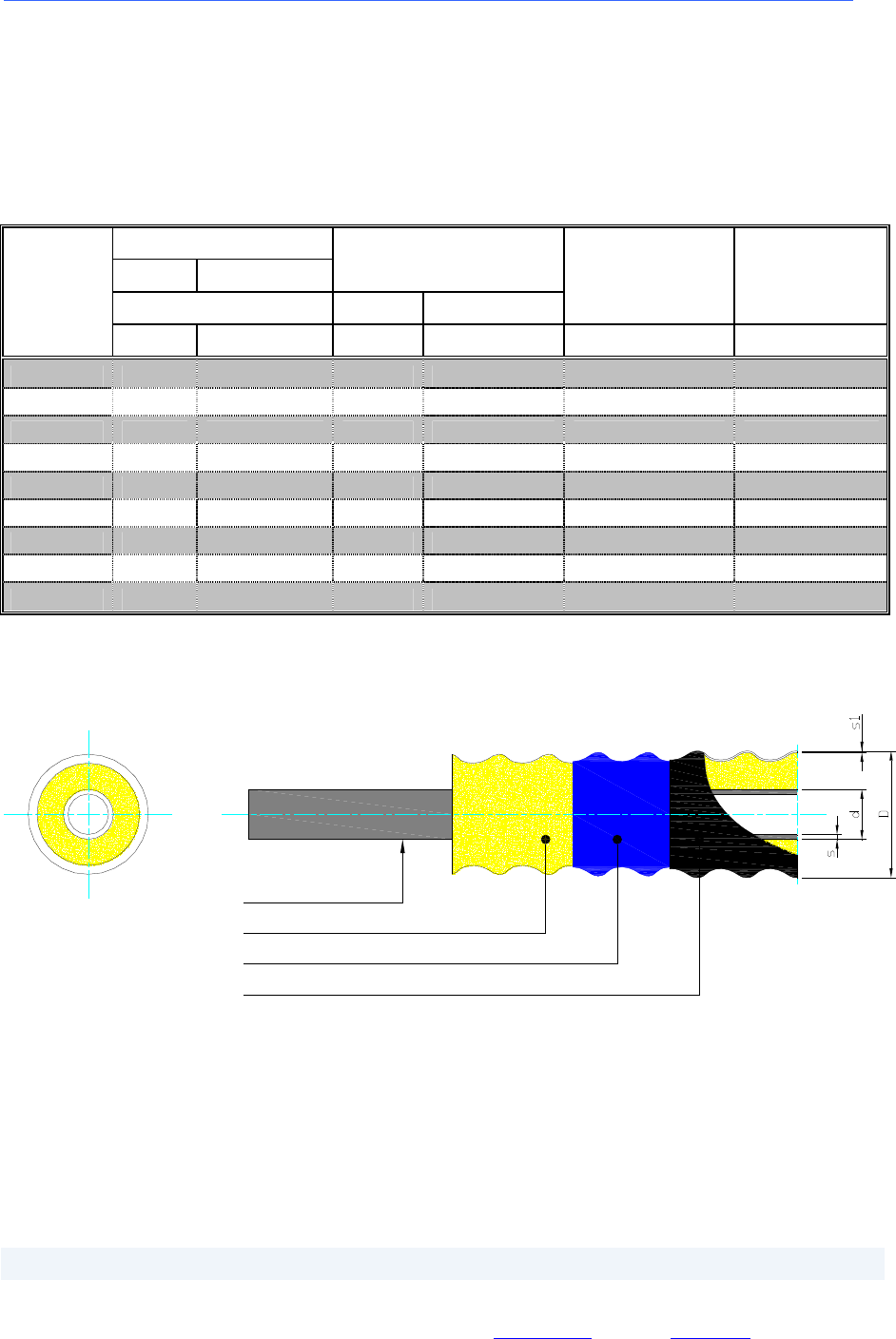

1.3.1 End Seals

All pipes and fittings ends could be supplied with a heat shrinkable end seal to prevent moisture from

penetrating into the foam insulation.

For preinsulated pipes with GRP jacket, fiberglass mat with resin shall be applied to the exposed

insulation ends to form a watertight end seal.

1.3.2 Anchors

Table 1.3.0-A: Series I

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

W

d

W

T

D

Table 1.3.0-B: Series 2

Steel Pipe HDPE Casing M.S. Anchor Plate

Steel Pipe HDPE Casing M.S. Anchor Plate

Nominal Diameter Outside Diameter Thickness Diameter

d D T W

Inch mm mm mm

¾ 90 15 200

1 110

15

200

1¼ 125

15

250

1½ 125

15

250

2 140

15

250

2½ 168

15

315

3 180

15

315

4 200

15

390

5 220 15 390

6 250 25 450

8 315 25 515

10 355 30 600

12 400 35 600

14 450 35 650

16 500 40 700

18 560 40 760

20 630 40 830

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Nominal Diameter

Outside Diameter Thickness Diameter

d D T W

Inch mm mm mm

¾ 110 15 200

1 125

15

250

1¼ 140

15

250

1½ 168

15

315

2 180

15

315

2½ 200

15

390

3 220

15

390

4 250

15

450

5 280

15

480

6 315 25 515

8 355 25 600

10 400 30 600

12 450 35 650

14 500 35 700

16 560 40 760

18 630 40 830

20 630 40 830

W

d

W

T

D

1.3.3 Wall Entry Sleeve & Link Seals

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

Wall entry sleeves are used whenever the pipes passes through walls to form a seal against water

penetration.

The wall entry sleeve is made from rubber which allows movement at the entry point.

The outer casing should be thoroughly cleaned before the sleeve is slid over it. The sleeve is not

intended to be used as a pipe support.

When the pipe work passes through a wall next to vibrating equipment (such as pumps), it is recommended

to use a link seal instead of the above wall entry sleeve.

1.3.4 Expansion Joints

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

In long straight pipe runs, preinsulated expansion joints are used to absorb the expansion or contraction

movement.

EPPI uses externally pressurized guided expansion joints with multiply or laminated bellows

construction; with design pressure of 150 psig or 300 psig at a maximum temperature of 750º F.

Standard expansion joint is supplied with beveled ends for welded joints or with flanged ends.

1.4.0 FIELD JOINT INSULATION

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

(General Field Joint Insulation Instruction)

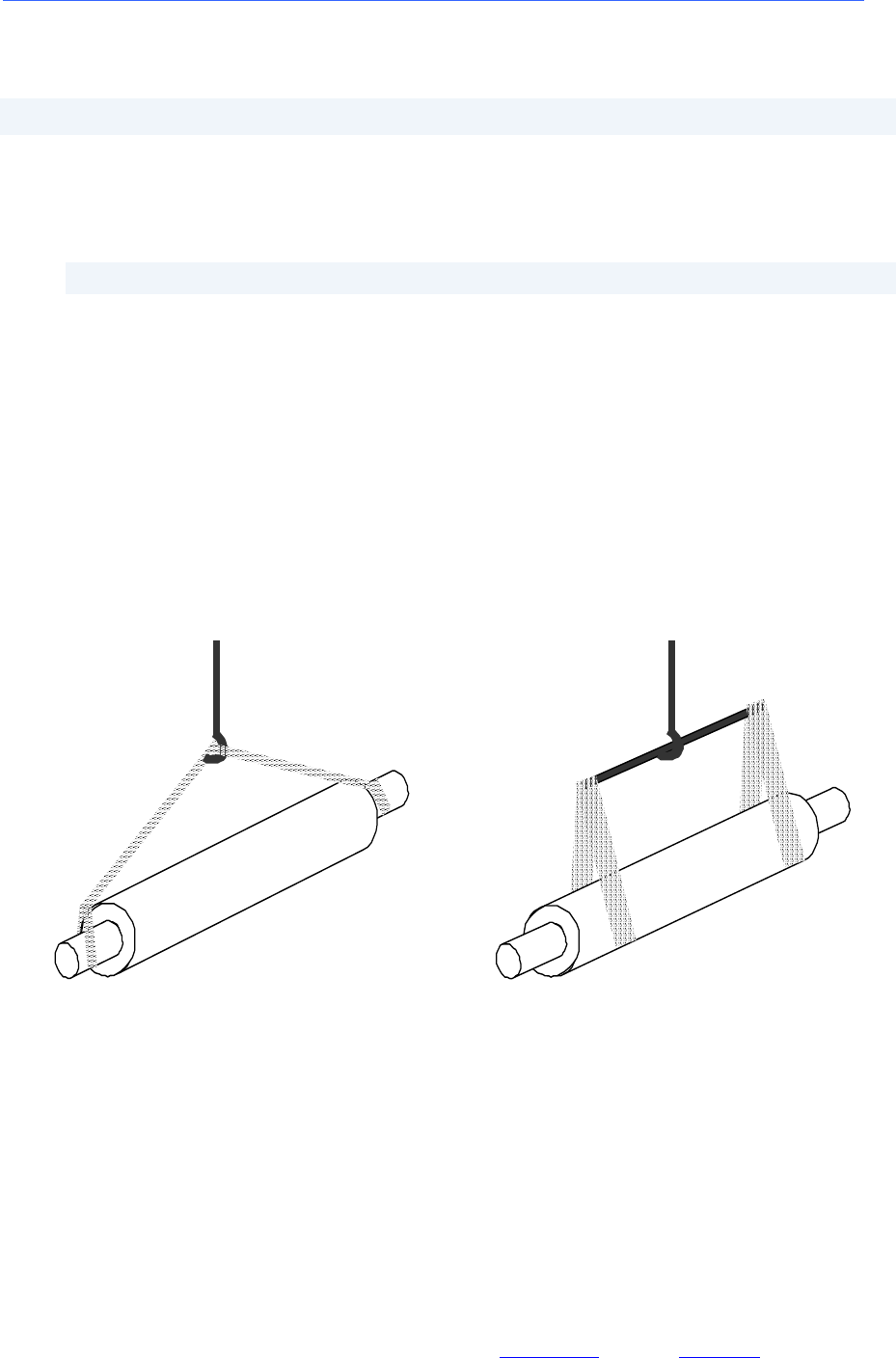

Field joint insulation shall be applied after the preinsulated pipes are installed, joined either mechanically using mechanical

couplings or by welding, and pressure-tested as per project’s specifications. If the preinsulated piping system is supplied with

leak detection/location system, please refer to the leak detection installation procedure prior to joint insulation.

Field insulation application at joints shall be as follows:

1.4.1 Joint Preparation

a) Slide the RayJoint sleeve over pipe end before welding. Keep Rayjoint Sleeve covered with the white plastic

cover as sun protection.

b) Ensure that the core pipe joint was tested and leak-free. Clean the surface of the pipe joint and remove any

foreign material around it. Make sure that it is clean and dry. Apply the specified coating material by brush

to the welded area and any scratched or damaged area of the steel core pipe.

1.4.2 Installation of RayJoint Sleeve

a) Mark the position of the RayJoint sleeve centered over the joint area.

b) Abrade the HDPE jacket that will be covered by the RayJoint.

c) Wrap the fiber reinforced sealing strips over the HDPE jacket. The strips edge should be next to the

marking. Make sure that the sealing strips overlap is located at the top of the HDPE jacket. Leave the

release plastic on the sealing strips. (Refer to table 1.4.0-A for the length of sealant strips to be cut for a given pipe size).

d) Slide the RayJoint sleeve carefully over the sealant strips and center it over the joint to be insulated. Make

sure that the Rayjoint sleeve overlap is not located on top. When the RayJoint sleeve is in place, remove the

release plastic from both sealing strips.

e) Drill one foaming hole at the top of RayJoint sleeve to allow air to escape during installation.

f) Wrap the heat shields tightly around the HDPE jacket next to the RayJoint sleeve. Check if it will not be

covered by the RayJoint sleeve when it shrinks. Wrap the second pair of heat shields tightly around the

RayJoint Sleeve.

g) Use a soft flame to provide sufficient heat that can penetrate the HDPE jacket. Apply heat on one end of

the RayJoint sleeve, moving the flame continuously around the circumference. Be sure not to burn the

surface.

1.4.3 Pressure Test

a) After cool down, 0.5 bar/7.25 PSI is applied to the Rayjoint sleeve for 10 minutes through the hole. Soap

water shall be carried out in the edges of the shrunk down RayJoint sleeve to ensure there is no leak.

1.4.4 Pouring of PUR Foam Chemicals

The temperature of the chemicals should always be maintained at 20° - 25° C.

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

a) After the RayJoint sleeve is tested and securely installed, weigh the exact amounts of chemicals: Polyol &

Isocyanate (ISO), in separate cups (Refer to the attached table for the proper weights of chemicals for a given pipe size).

Please note that Polyol has a distinctive smell, with a pale-to-dark yellow color; ISO is colored black. Both

chemicals should not be exposed to air-moisture or heat for long hours. Make sure that the chemical

containers are closed tightly after usage.

b) Drill a second hole at the top of the RayJoint casing which will serve as a vent hole so that there will be no

air trapped inside the casing.

c) First, pour the Polyol (weighed in a cup) into the mixing cup/bucket. When ready to mix, pour the ISO

(weighed in a cup) into the mixing cup/bucket with Polyol. Using the electric drill with mixer blade

attached, mix the two chemicals thoroughly. When the color of the mixture changes (from dark to pale

yellow) or when the mixture is starting to rise, pour immediately (as quickly as possible) the mixture through

the pouring hole of the RayJoint casing. Allow few minutes for the foam to rise, then plug the holes with

foaming plugs to refrain the foam from coming out of the hole.

d) Once the foaming is complete and the foam cures, seal the foaming holes using adhesive coated HDPE

closure patch (Type of FOPS). A good installation is defined by no foam leakage out of the sealant area and

full circumferential contact of shrunken edges of RayJoint with the HDPE jacket.

W E L D E D J O IN T

1 .

2 .

3 .

4 .

H D P E J A C K E T C O R E P IP E

7 0 0 m m

S E A L IN G S T R IP

R A Y J O IN T S L E E V EF O A M IN G H O L E

P R E S S U R E T ES T

C F C - F R E E P O L Y U R E T H AN E F O A M

C L O S U R E P A T C H

Table 1.4.0-A: Field Insulation Materials – Welded Joints

Core

Casing

RayJoint

Sealing

PUR

POL

ISO

POL

ISO Volume,

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

N.D.

inch

(mm)

N.D.

mm

Internal

Ø,

mm

Str

ip

Length,

mm

Weight,

Kg/Jnt

Weight,

Kg/Jnt

Weight,

Kg/Jnt

Volume,

L/Jnt

L/Jnt

48 (1200)

1400 1491 4517 16.7 6.4 10.3 5.9 8.3

36 (900) 1100 1179 3531 12.5 4.8 7.7 4.5 6.3

30 (750) 900 971 2902 8.2 3.2 5.0 2.9 4.1

24 (600)

730

867

2368

8.6

3.3

5.3

3.1

4.3

20 (500) 630 687 2054 4.8 1.9 3.0 1.7 2.4

18 (450)

560

615

1834

3.8

1.5

2.4

1.4

1.9

16 (400) 560 615 1834 4.8 1.9 3.0 1.7 2.4

14 (350) 500 551 1646 4.0 1.5 2.5 1.4 2.0

12 (300)

450

498

1489

3.2

1.2

2.0

1.2

1.6

10 (250) 400 447 1332 2.8 1.1 1.7 1.0 1.4

8 (200)

355

394

1190

2.4

0.9

1.5

0.9

1.2

6 (150) 280 320 930 1.7 0.6 1.0 0.6 0.8

4 (100) 225 250 757 1.1 0.4 0.7 0.4 0.6

N.B. Actual figures may be slightly different due to:

a. The requirement of different insulation thicknesses / different jackets sizes than those in the above

table.

b. Site Ambient Conditions.

1.5.0 RIGID PREINSULATED PIPING SYSTEM FOR

LARGE DIAMETERS

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

The preinsulated pipe consists of either Steel or HDPE core pipe, 100% CFC free thermal insulation and Glass-

Fiber Reinforced Polyester (GRP) jacket pipe.

Table 1.5.0-A

Steel Pipe GRP Casing Insulation

Overall Weight

Nominal Diameter

OD

ID

Thickness

48 kg/m

3

60 kg/m

3

in mm mm mm kg/m kg/m

44

1118

1300

91

670.91

722.84

46 1150 1300 75 683.83 735.08

48 1219 1400 90.5 751.35 811.24

52 1321 1500 89.5 837.27 905.64

56

1422

1600

89

925.20

1,002.65

1.5.1 G

LASS

-F

IBER

R

EINFORCED

P

OLYESTER

(GRP)

P

ROTECTIVE

J

ACKET

The protective jacket shall be made of multi-directional filament wound glass reinforced polyester (GRP)

resin.

Table 1.5.0-B

Physical Properties

Values

Barcol hardness 35 min.

Flexural strength (ultimate) psi 19,000 (131,000 kPa) min.

ASTM D790

Tensile strength, psi 12,000 (82,740 kPa) min.

ASTM D638

Compressive strength, psi

22,000 (151,685 kPa) min.

ASTM D695

Glass Content 60% (nominal)

Fire retardant GRP is also available with flame spread of ≤25 and smoke development of ≤500 conforming

to ASTM E84.

1.6.0 RIGID PREINSULATED HIGH DENSITY

POLYETHYLENE (HDPE) PIPING SYSTEM

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

The preinsulated pipe consists of High Density Polyethylene (HDPE) core pipe, 100% CFC free thermal

insulation and High Density Polyethylene (HDPE) protective jacket.

This system is becoming increasingly popular due to its flexibility, smooth surface, low friction coefficient factors,

light weight, corrosion resistance and low thermal coefficient.

Table 1.6.0-A

HDPE Core Pipe HDPE Casing

Insulation

Thickness

Overall Weight (kg/m)

Nominal Dia.

OD

OD

SDR11/PN16

SDR17/PN10

in mm mm mm 48 kg/m

3

60 kg/m

3

48 kg/m

3

60 kg/m

3

5

125 250 58.9 21.45 23.59 16.98 20.87

5½

140

250

51.4

23.18

25.28

18.14

22.28

6¼

160 280 56.1 28.21 30.84 22.15 27.18

7¼

180 280 46.1 31.02 33.59 23.97 29.25

8

200 315 53.4 37.20 40.47 29.06 35.28

9

225 355 60.5 45.47 49.63 35.82 43.10

10

250

400

70.2

55.29

60.59

43.91

52.29

11¼

280 400 55.2 61.86 67.01 48.18 56.05

12½

315

450

62.3

76.99

83.51

60.

38

68.72

14¼ 355 500

66.9 95.85 103.88 75.35 83.34

16 400 560

74 121.14 131.20 95.30 102.01

18 450 560

49 142.15 151.81 109.52 110.41

20 500 630

58.4 179.12 191.41 139.02 134.97

22¼ 560 710

67.8

229.99

245.66

179.18

166.33

25¼ 630 800

77.1 298.94 318.85 234.24 206.46

28¼ 710 900

86.3 392.22 417.42 307.79 256.19

32 800 1000

90.6 - - 403.16 314.21

36 900 1100

89.8 - - 523.95 380.00

40 1000 1200

89 - - 669.30 453.66

1.6.1 H

IGH

D

ENSITY

P

OLYETHYLENE

(HDPE)

C

ORE

P

IPE

E

mirates

P

reinsulated

P

ipes

I

ndustries---------------------------------------------------------------------------Engineered Preinsulated Piping Systems

P.O.Box 73830, Abu Dhabi – UAE

TEL: (+971) 2 550 1991 FAX: (+971) 2 550 1992 EMAIL: GMai[email protected]e WEBSITE: www.eppi.ae

The core pipe shall be rigid seamless high density polyethylene (HDPE), black, conforming to ISO 4427,

DIN 8075 & 8074, PE100, SDR17, MRS10, with a safety factor of 1.25 at 20* C for 50 years. These pipes

don't require blasting or coating since they are resistant to corrosion and rust.

Table 1.6.0-A: HDPE Pipe Dimensions

(Based on ISO 4427 and DIN 8074)

Nominal

O.D.

(mm)

Standard

Dimension

Ratio (SDR)

SDR 11 SDR 17

Nominal Pressure Rating (PN)

PN 16 PN 10

Nominal Wall

Thickness (mm)

Nominal Weight

(kg/m)

Nominal Wall Thickness

(mm)

Nominal Weight

(kg/m)

125 11.4 4.08 7.4 2.76

140 12.7 5.08 8.3 3.46

160 14.6 6.67 9.5 4.52

180 16.4 8.42 10.7 5.71

200 18.2 10.4 11.9 7.05

225 20.5 13.1 13.4 8.93

250 22.7 16.2 14.8 11