LED Illumination System for Channel Letters and 12VDC Power

Supplies Installation Guide

Rev.

102

1

LED Illumination System for Channel Letters and 12VDC

Power Supplies Installation Guide

Products covered in this guide:

LED Module: Part Number Description

JE-001R Standard Red LED Module 100 pieces/box

JE-002G Standard Green LED Module 100 pieces/box

JE-003B Standard Blue LED Module100 pieces/box

JE-004W Standard White LED Module100 pieces/box

JE-005A Standard Amber LED Module100 pieces/box

JE-001RU Super Red LED Module 50 pieces/box

JE-002GU Super Green LED Module 50 pieces/box

JE-003BU Super Blue LED Module 50 pieces/box

JE-004WU Super White LED Module 50 pieces/box

JE-005AU Super Amber LED Module 50 pieces/box

Fig.1

LED Modules options: Clockwise from top left, whole box of Standard LED modules,

whole box

of Super LED modules, single piece of standard LED modules and single piece of super LED modules

LED Illumination System for Channel Letters and 12VDC Power

Supplies Installation Guide

Rev.

102

2

Power Supplies: Part Number Description

AD-4212 12VDC/3.3Amp/40Watt, Indoor power supply

MJ-1220 12VDC/1.6Amp/20Watt, Class 2 UL1310 Power supply

MJ-1240 12VDC/3.3Amp/40Watt, Class 2 UL1310 Power supply

MJ-1260 12VDC/5.0Amp/60Watt, Class 2 UL1310 Power supply

Fig.2

Power Supply options: Clockwise from top left, 40Watt Indoor AD-4212L,

20Watt Class

2

MJ-1220, 40Watt Class

2 MJ-1240 and 60Watt Class2 MJ-1260

LED Illumination System for Channel Letters and 12VDC Power

Supplies Installation Guide

Rev.

102

3

Scope

Attention!

□ This procedure is designed to aid in the installation of J’s LED Power Inc. LED

Module channel letter illumination product.

□ Skilled trades people that are familiar with general construction, electrical and

sign installation techniques should do the installation.

□ Licensed electricians should provide all installation and hook-up of both the

primary input and secondary outputs of the Power Supply.

□ All installation and hook-up should be done in accordance with all national and

local codes.

□ In no way is this document intended to construe warranty or fitness of use of the

products described, nor is it intended to provide safety instruction for those

installing the product.

CAUTION: TURN OFF ALL INTEGRAL DISCONNECTS BEFORE SERVICING (IF

INTEGRAL DISCONNECTS ARE NOT PROVIDED, TURN OFF POWER TO THE

SIGN BY OTHER MEANS i.e. TURN OFF THE CIRCUIT BREAKER OR REMOVE

THE FUSE AT THE SERVICE PANEL).

THE FIELD ASSEMBLY OF THIS SECTIONAL SIGN IS SUBJECT TO THE

ACCEPTANCE OF LOCAL INSPECTION AUTHORITY.

LED Illumination System for Channel Letters and 12VDC Power

Supplies Installation Guide

Rev.

102

4

LED Modules

Attention!

J’S LED Power Inc. LED Modules are

a low voltage, long life alternative to neon and florescent

lighting for channel letters.

The light source for

the LED Module is the Light Emitting Diode (LED)

instead of traditional neon or florescent tubes.

LED technology allows

the LED Modules to

provide excellent color and brightness in a safe, low voltage circuit (12 Volts DC).

LED Modules

are

a robust, easily installed product designed for a long life of safe, maintenance free operation.

Fig.3

LED

Module Layout. All modules operate on 12VDC and can be run by the same

power supply.

Tools Required

1. Wire stripper/cutter

2. Measuring Tape

3. Drill

4. Screw Drivers

Standard Hardware and Supplies

(UL listing may be required on

certain items)

(Supplies listed below may be purchased from

J’s LED Power Inc.)

1.

Silicon Glue

2.

Splice connector or Molex IDC (Insulation Displacement Connector) Type

3.

4” or 8” nylon zip ties

4.

18 AWG UL Listed PLCC

Fig.4

Hardware

LED Illumination System for Channel Letters and 12VDC Power

Supplies Installation Guide

Rev.

102

5

Populating the Channel Letter

Populating a channel letter with

LED Modules is as easy as peeling the liner off the

mounting tape and firmly pressing the light modules in the desired locations.

NOTE:

Bonding surface should be clean and dry.

To determine where the

LED Modules

should be placed and how many to use,

J’s LED Power

Inc.

offers the following guidelines: (Results may vary based

upon desired light intensity and

letter construction).

1.

LED Modules

are designed to be place in rows:

a.

LED Modules should have approximately 2.5 inch

spacing between modules within the row.

This will result in 3 modules per foot.

2.

LED Modules

are designed to cover a stroke width of

4 inch in a channel letter (letter depth of

4

to 8 inches). Letters with a 4 inch stroke width or smaller should have one 1 row of LED

Modules. Letters with a stroke width larger than 4 inches should have multiple rows of LED

Modules placed according to the following schedule;

a.

4

to 6 inch stroke= 2 rows b.

6 to 8 inch stroke= 3 rows c.

8

to 10 inch stroke= 4 rows

d.

Actual

number of rows/modules may vary depending upon the application. The

above schedule is offered only as a guideline.

3.

When all modules are in place, the secondary output from the power supply can be

connected.

Multiple

letters in a sign

must be connected to the power supply in parallel.

Use

UL listed Insulation

Displacement Connectors to make this connection and to cap off

the open ends of

the row.

Fig.5

Example of

24” Channel letter with 4” stroke populated with one stroke of

LED Modules.

LED Illumination System for Channel Letters and 12VDC Power

Supplies Installation Guide

Rev.

102

6

If extra wire is needed

between units, use UL

listed 20 AWG or larger

Fig.

5

Sample Sign Layout and Connections

4. Put

Silicon Glue at least two points on each side of each LED modules.

Fig.

6

Sample Sign Layout and Connections

NOTE:

All

LED Modules operate on 12VDC.

All

color modules can be connected to the same

power supply. Colors can be mixed on the same power supply. Different colors

can be

connected to the same power supply and mixed on the same power supply output.

LED Illumination System for Channel Letters and 12VDC Power

Supplies Installation Guide

Rev.

102

7

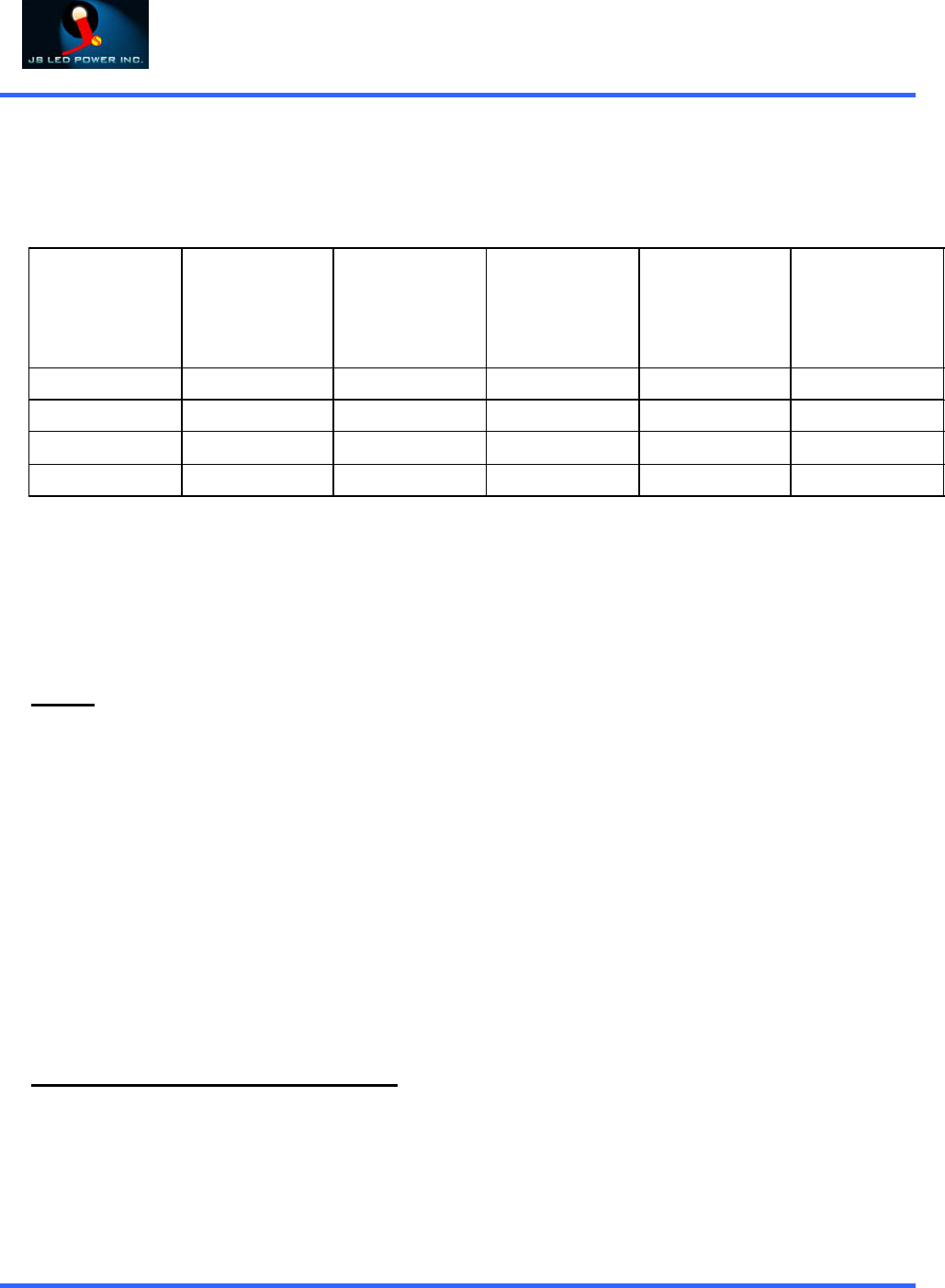

Power Supply Loading for

LED Module

LED Module

Type

Modules

per

Foot

Maximum

Modules per

40Watt

Remote

(Indoor)

Power

Supply

Maximum

Modules per

20Watt

Class2

(Outdoor)

Remote

Power

Supply

Maximum

Modules per

40Watt

Class2

(Outdoor)

Remote

Power

Supply

Maximum

Modules per

60Watt

Class2

(Outdoor)

Remote

Power

Supply

JE-001R

(Standard Red)

3 100 50 100 150

JE-002G

(Standard Green)

3 100 50 100 150

JE-003B

(Standard Blue)

3 100 50 100 150

JE-004W

(Standard White)

3 100 50 100 150

JE-005A

(Standard Amber)

3 100 50 100 150

JE-006M

(Standard RGB)

3 44 22 44 66

JE-001RU

(Super Red)

3 57 28 57 85

JE-002GU

(Super Green)

3 57 28 57 85

JE-003BU

(Super Blue)

3 57 28 57 85

JE-004WU

(Super White)

3 57 28 57 85

JE-005AU

(Super Amber)

3 57 28 57 85

Table1:

Power Supply Loading table

LED Illumination System for Channel Letters and 12VDC Power

Supplies Installation Guide

Rev.

102

8

Power Supply Installation

Mounting

Mount the power supply directly to the wall with #8 or #10 pan head screws.

The power

supply must be mounted in a well ventilated area that allows for accessibility after installation

and must not be adjacent to combustible materials or in an area that exceeds temperatures

of 50°C (122°F).

Mount the power supply indoors, out of the weather, and do not leave

exposed to rain or water.

For outdoor or wet location,

power supply

can

be enclosed inside

a raceway, inside the channel letter itself, in a UL Listed for wet location transformer box or in

a NEMA 3R box with ventilation.

Some acceptable Boxes for power supplies being mounted

outdoors are Hoffman p/n A12R126, Wes trim TC18SO-UL or equivalent. Use of a Class

2

power supply can also be used for outdoor or wet locations.

Connecting the Primary

After securely mounting the power supply, have the primary connected by a licensed

electrician in accordance with local and national codes. For the 40Watt Remote Power

Supply simply plug the AC power cord into a standard 3 prong grounded outlet.

LED Illumination System for Channel Letters and 12VDC Power

Supplies Installation Guide

Rev.

102

9

Connecting the Output

LED, Inc power supplies have Class

2 DC outputs. For reliability and performance the

following loading is not to be exceeded.

Power

Supply Part

Number

Outputs

Input

Voltage

(Volts- AC)

Output

Power

(Watts)

Output

Voltage

(Volts- DC)

Maximum

Output

Current

(Amps)

AD-4212L 1 100-240 40 12 3.3

MJ-1220 1 90-264 20 12 1.6

MJ-1240 1 90-264 40 12 3.3

MJ-1260 1 90-264 60 12 5

Table2:

Power Supply Output Table

It is recommended that the current be checked on each power supply output after loading is

complete. The current drawn by each leg should not exceed the current rating on the power

supply label. If the measured current does exceed the rated current, reduce the number of

LED modules on that leg until the current is below the rated output.

The total number of

module per power supply is not to exceed the schedule as shown in Table 1.

NOTE:

If any power supply output leads are left unused, the

not terminated

wires must be

individually capped inside an UL Listed junction box, race way

or sign housing.

Routing Secondary Wires

When wiring the secondary outputs of the power supply, all routing through walls must be

sealed with outdoor rated caulk to protect the sign and building from water damage and the

cable from chafing. The power supply leads and letter to letter

jumpers can be routed

through walls, inside and outside without conduit. It is

recommended that all connections be

enclosed in a UL listed junction box with strain

relief.

Extension of Power Supply Leads

If a longer lead wire from the power supply to lighting modules is needed, an extension

can be used. The extension should be kept as short as possible (under 15 feet for 18 AWG

UL Listed or under 50 feet for 14 AWG UL Listed).

WARNING: CHECK POLARITY

After all wire routing is complete and the lighting modules are connected to the power

supply,

RECHECK THE POLARITY OF ALL CONNECTIONS.

Reverse polarity connections may damage

the LED modules and voids the product warranty.

LED Illumination System for Channel Letters and 12VDC Power

Supplies Installation Guide

Rev.

102

10

Power Supply

Dimensions

Fig.7

Overall Dimensions for

J’S LED Power

Inc. 12VDC, 40Watt, Power Supply AD-4212L

LED Illumination System for Channel Letters and 12VDC Power

Supplies Installation Guide

Rev.

102

11

Fig.

8

Overall Dimensions for

J’S LED Power

Inc. 12VDC,

20Watt,

Class

2 Power Supply (MJ-1220)

LED Illumination System for Channel Letters and 12VDC

Power Supplies Installation Guide

Rev.

102

12

Fig.

9

Overall Dimensions for

J’s LED Power Inc.

12VDC, 40Watt,

Class

2 Power Supply

(MJ-1240)

LED Illumination System for Channel Letters and 12VDC

Power Supplies Installation Guide

Rev.

102

13

Fig.

10

Overall Dimensions for

J’s LED Power Inc.

12VDC, 60Watt,

Class

2

Power

LED Illumination System for Channel Letters and 12VDC

Power Supplies Installation Guide

Rev.

102

14

Supply(MJ-1260)

Trouble Shooting Guide

Entire sign or leg with LED Modules does not light after complete

installation.

□

Check the connection from the power supply lead to the first

LED Module.

Make

sure the polarity of the connections made at the power supply lead and any jumper

wire is

correct.

Still does not light.

□

Using a volt meter check the output voltage of the power supply.

The output

voltage should

be 12.0VDC +or- 0.5VDC.

If there is no output voltage, have a

licensed electrician check

input voltage.

Make sure the power supply is

hooked up correctly and getting primary

power.

If the power supply is hooked

up correctly and getting primary power and there is

still no output voltage,

replace the power supply with a new one.

The beginning of a LED Module leg lights, but the entire leg does not

light or lights intermittently.

□

The primary cause of a portion of a LED Module leg not lighting or lighting

intermittently is

a bad connection between the modules that light and the

modules that don’t light. Check

this connection.

One LED Module does not light, but all others in the leg light.

□

LED Modules are designed so if one module fails, it will not cause the entire sign

or leg to go

out.

If one

LED Module is not lighting, but all others in the leg are lighting,

replace the module with a new one.