PRODUCT RETROFIT GUIDE

PAGE 1 OF 7

A Principal Industries Company

Cabinets and Channel Letters

Module and Stik

™

Families

Qwik Mod Series, Patriot Series, Choice Modules, Tap Out Modules, Street Fighter Modules, Pinnacle Modules, Tap Out Stik

™

,

Pinnacle HE Stik

™

, Patriot Stik

™

, Prism Synergy Stik Deep, Prism Synergy Stik HO.

Warning

• Installation must only be performed by a licensed electrician.

• To prevent death, injury or damage to property this product

must be installed in accordance with the National Electric Code

in the USA or Canadian Electrical Code (CSA22.1) in Canada.

• Install according to Kit Model: PL-RT1-001. Go to

PrincipalSloan.com for details.

• This guide covers the kit model PL-RT1-001 and is to only

include the UL recognized LED products and power supplies

found in this manual and UL file E341517.

• WARNING: Risk of fire or electric shock. LED Retrofit Kit

installation requires knowledge of sign electrical systems. If

not qualified, do not attempt installation. Contact a qualified

electrician.

• WARNING: Risk of fire or electric shock. Install this kit only

in host signs that have been identified in the installation

instructions and where the input rating of the retrofit kit

does not exceed the input rating of the sign.

• WARNING: Risk of fire or electric shock. Installation of this

LED retrofit kit may involve drilling or punching of holes into

the structure of the sign. Check for enclosed wiring and

components to avoid damage to wiring and electrical parts.

• Installer should examine all parts that are not intended to

be replaced by the retrofit kit for damage and replace any

damaged parts prior to installation of the retrofit kit.

• Installers should not disconnect existing wires from

lampholder terminals to make new connections at

lampholder terminals. Instead installers should cut existing

lampholder leads away from the lampholder and make

new electrical connections to lampholder lead wires by

employing applicable connectors.

• WARNING: To prevent wiring damage or abrasion, do not

expose wiring to edges of sheet metal or other sharp objects.

• Do not make or alter any open holes in an enclosure of wiring

or electrical components during kit installation.

• Repair and seal any unused openings in the electrical

enclosure. Openings greater than 0.5" (12.7 mm) diameter

require a metal patch secured by screws or rivets and

caulked with non-hardening caulk. Smaller openings may be

sealed with non-hardening caulk.

• WARNING: To avoid potential fire or shock hazard, do not

use this retrofit kit with existing shunted bi-pin lampholders

in the host sign. Note: Shunted lampholders are found only

in fluorescent signs with Instant-Start ballasts. Instant-start

ballasts can be identified by the words "Instant Start" or

"I.S." marked on the ballast. This designation may be in the

form of a statement pertaining to the ballast itself, or may

be combined with the marking for the lamps with which the

ballast is intended to be used, for example F40T12/IS. For

more information, contact the LED retrofit kit manufacturer.

• "This sign has been modified to operate LED lamps. Do

not attempt to install or operate lamps in this sign." shall

be marked on the retrofitted sign where readily visible by

the user during normal maintenance including relamping.

"Lamps in this sign shall be replaced by the original

illumination type such as ‘fluorescent,’ ‘HID,’ etc." This

marking shall be provided on a separate permanent label

that is intended to remain in the applied position for the

lifetime of the sign under conditions of normal use.

GENERAL PURPOSE

RETROFIT SIGN CONVERSION

FOR USE ONLY IN ACCORDANCE

WITH KIT INSTRUCTIONS

KIT IS COMPLETE ONLY WHEN ALL PARTS REQUIRED

BY THE INSTRUCTIONS ARE PRESENT

This product is covered by issued U.S. Patent No. 9,851,054 and 10,024,501.

PRODUCT RETROFIT GUIDE

PAGE 2 OF 7

A Principal Industries Company

Cabinets and Channel Letters

All UL part number for the products listed below are based on the master part number found within E341517: PL-XX#-BBO-Z/DD-WW-A-YYV-T(HH)

MODEL NUMBER NOMENCLATURE - The following describes the nomenclature of Class 2 LED Modules,

designated as PL-XX#-BBO-Z/DD-WW-A-YYV-T(HH) Series:

Product name UL part number SKU Input voltage (VDC) Power (W) Units/60W

MODULES

Qwik Mod 1 PL-QM1-YYV-P M-QMSX0-YY 12.00 0.40 150

Qwik Mod 2 PL-QM2-YYV-P M-QMDX0-Y Y 12.00 0.80 76

Qwik Mod 3 PL-QM3-YYV-P M-QMTX0-YY 12.00 1.20 50

Qwik Mod 4 PL-QM4-YYV-P M-QMQX0-YY 12.00 1.60 38

Choice PL-SF-CH-P M-SFCX0-YY 12.00 0.80 72

Choice HO PL-SF-HO-P M-SFCXH-YY 12.00 1.25 48

Street Fighter Pod 1 PL-OP2-PD1-P-YY M-SFPS1-YY 12.00 1.32 44

Street Fighter Pod 2 PL-OP2-PD2-P-YY M-SFPD2-YY 12.00 2.50 24

Street Fighter Pod 3 PL-OP2-PD3-P-YY M-SFPT3-YY 12.00 1.32 44

Street Fighter RGB PL-OP2-SC3-P-RG M-SFCX3-3C 12.00 0.65 90

Street Fighter Tap Out 12V PL-OP2-TO3-P-YY M-SFTO3-YY 12.00 1.32 45

ASSEMBLIES

Tap Out 12V Stik Single-sided PL-OP2-TO3-P/ST-SS-A-Y B-TO-SV-AYY 12.00 5.28-29.04 11-2

Tap Out 12V Stik Double-sided PL-OP2-TO3-P/ST-DS-A-Y B-TO-DV-AY Y 12.00 10.56-58.08 5-1

Product name UL part number SKU Input voltage (VDC) Power (W) Units/96W

MODULES

Patriot Small PL-PT#-SM-P M-PTSM0-YY 24.00 0.40 240

Patriot Medium PL-PT#-MD-P M-PTMD0-YY 24.00 0.80 120

Patriot Large PL-PT#-LG-P M-PTLG0-Y Y 24.00 1.07 90

Patriot XL PL-PT#-XL-P M-PTXL0-YY 24.00 1.33 72

Patriot Deep PL-PT#-XD-P M-PTXD0-YY 24.00 1.33 72

Pinnacle HE PL-OP1-TO4-P M-SFTO4-YY-24 24.00 1.32 72

Street Fighter Tap Out 24V PL-SF24-TO3-P MSFTO3-YY-24 24.00 1.32 72

ASSEMBLIES

Patriot XL Stik Single-sided PL-PT#-XL-P/ST-SS-A B-PT-SV-AYY-XL 24.00 2.66-23.94 36-4

Patriot XL Stik Double-sided PL-PT#-XL-P/ST-DS-A B-PT-DV-AYY-XL 24.00 5.32-47.88 18-2

Patriot XL Deep Stik Single-sided PL-PT#-XD-P/ST-SS-A B-PT-SV-AYY-XD 24.00 2.66-23.94 36-4

Patriot XL Deep Stik Double-sided PL-PT#-XD-P/ST-DS-A B-PT-DV-AYY-XD 24.00 5.32-47.88 18-2

Pinnacle HE 24V Single-sided Stik PL-OP1-TO4-P/ST-SS-A-Y Y B-TP-SV-AYY-24-HE 24.00 2.64-15.84 36-6

Pinnacle HE 24V Double-sided Stik PL-OP1-TO4-P/ST-DS-A-YY B-TP-DV-AYY-24-HE 24.00 5.28-31.68 18-3

Prism Synergy Stik Deep Single-sided PL-SY4-DP2-P/ST-SS-YY Y B-SY-SXX-YYYZZ-DP 24.00 3.99-23.94 4-24

Prism Synergy Stik Deep Double-sided PL-SY4-DP2-P/ST-DS-YYY B-SY-DXX-YYYZZ-DP 24.00 7.98-47.88 12-2

Prism Synergy Stik HO Single-sided PL-SY4-HO1-P/ST-SS-YYY B-SY-SXX-YYYZZ-HO 24.00 2.66-15.96 36-6

Prism Synergy Stik HO Double-sided PL-SY4-HO1-P/ST-DS-YYY B-SY-DXX-YYYZZ-HO 24.00 5.32-31.92 18-3

Tap Out 24V Stik Single-sided PL-OP2-TO3-P/ST-SS-A-Y Y24 B-TO-SV-AYY-24 24.00 5.28-29.04 18-3

Tap Out 24V Stik Double-sided PL-OP2-TO3-P/ST-DS-A-YY24 B-TO-DV-AY Y-24 24.00 10.56-58.08 9-1

24V Products

1. PL (Principal LED) - represent the series designation

2. XX - represents different LED module series

3. # - represents numerical designation for LED model of different lengths of assemblies

4. BB - represents the different LED model within the LED module series

5. O - represents the number of LED diodes on the LED model

6. Z - represents the plastic housing of each module where N stands for No Housing and P stands

for Potted with Housing

7. DD - represents the stick designation for assembly models

8. WW - represents the number of sides that LED modules are mounted to on assemblies

9. A - represents different length of the PWB

10. YY - represents different color or color temperature of LEDs

11. V - represents LED series numbering designation

12. T - represents the plastic housing of each module where N stands for No Housing and P

stands for Potted with Housing

13. HH - represents additional assembly specifications

PL-XX#BBO-Z/DD-WW-A-YYV-T(HH) Series, where XX may be any combination of letters for AA to ZZ; # may be

any numeric character 0-999; BB may be any combination of letters AA to ZZ or may be left blank; O may be any

number 0-999 or may be left blank; Z may be letter N or P or may be left blank; /DD may be any combination of

letters AA to ZZ or may be left blank; WW may be letters SS (Single Sided), DS (Double Sided), TS (Triple Sided),

or SH (Four Sided) or may be left blank; A may be any number 0 to 999 or may be left blank; YY may be any

combination of letters AA to ZZ; V may be any number 0 TO 999 or may be left blank, T may be letter N or P or may

be left blank; (HH) may be alphanumeric combination or may be left blank.

A Principal Industries Company

PRODUCT RETROFIT GUIDE

PAGE 4 OF 7

A Principal Industries Company

Cabinets and Channel Letters

Principal Sloan Power Supplies

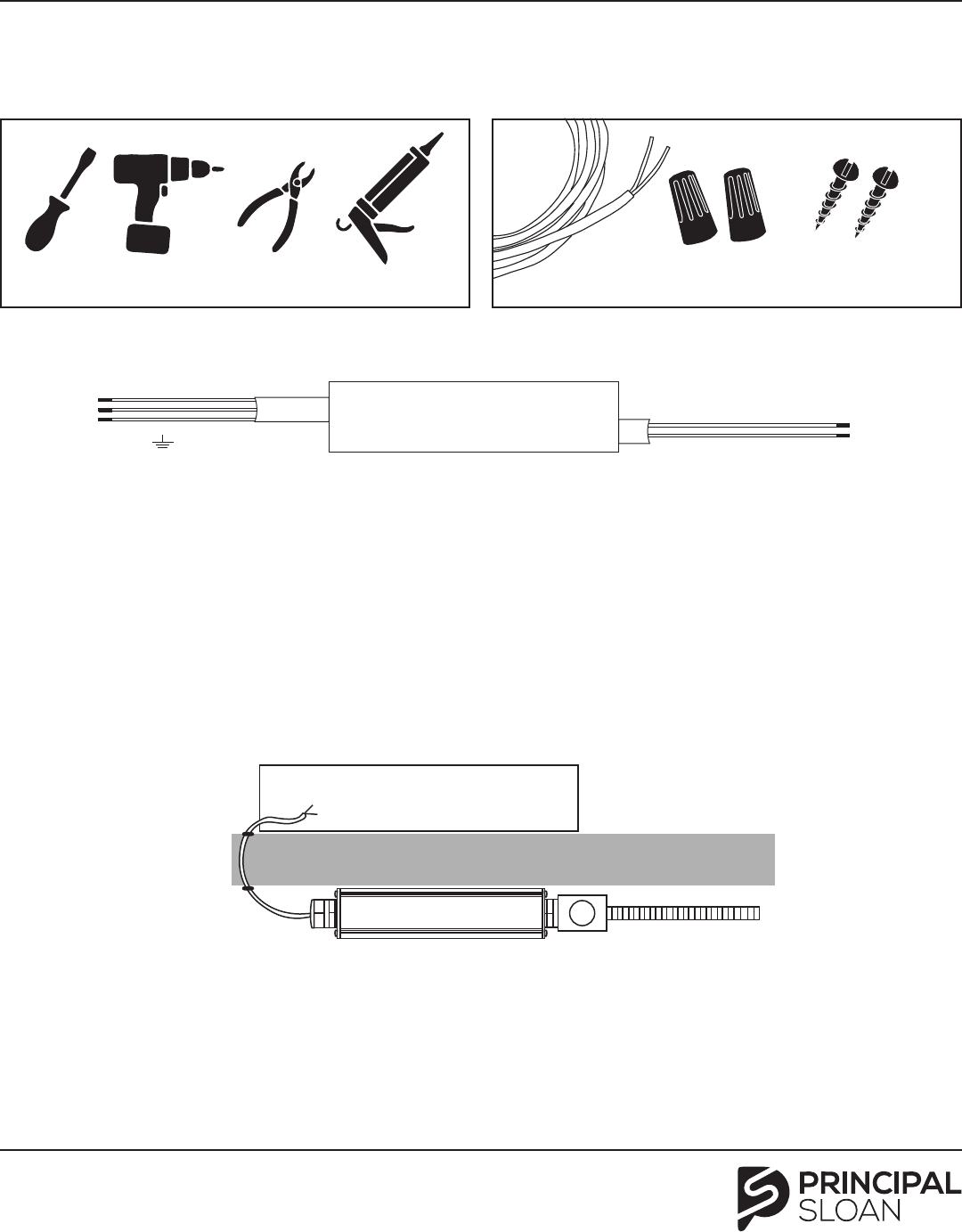

Tools required Supplies required

Screwdriver, Drill, Wire Stripper, Silicone and Gun UL Listed PTLC Cable, Wire Nuts, #8 Panhead Screws

Power Supply:

Primary side:

AC/L (Black)

AC/N (White)

Secondary side:

V+ (Red)

V- (Black/Blue)

FG (Green)

Make secondary connections:

Secondary output is 12VDC or 24VDC.

Secondary Class 2 Cables DO NOT require

conduit per NEC 2008 Articles 725.121-

130. Always seal wall penetrations

carefully to prevent water damage.

NOTE: Do not exceed 5A DC load. To minimize light loss it is

recommended to split the load equally in two parallel runs

(2.5A) of LED modules, or wire the secondary input to both

ends of the fully loaded 5A strand of LEDs

Mount power supply: Using a drill and

the #8 Panhead screws, mount the

power supply using the mounting tabs

at the bottom of the supply.

Make primary connection: A licensed

electrician is required in order to bring

conduit to the junction box and make

the primary connection.

Sign cabinet or channel letter

Power supply UL Listed

J-Box

Secondary output connection

Primary power

conduit

Wall penetration

(fill with silicone)

Attach power supply to J-box: Attach power supply(s) to

junction box using 0.5" locknut. Multiple power supplies may

be connected and configured to the same junction box.

For wet locations, use a junction box that is UL-rated for wet use.

NOTE: Operating temperature is -22º to 140º F (-30º to 60º C) therefore it is required by UL that the power supplies are spaced at least 2" (51 mm) apart side-to-side, 1"

(25 mm) end to end, and not in secondary enclosure to ensure optimal ventilation to ensure maximum lifetime of the power supply, it is highly recommended that a photo-

cell or timer be used to prevent operation during daylight hours. Do not use more modules than recommended on the product installation guide. Total amperage should

not exceed 5.0 A per power supply

0.5" (13 mm) Locknut

Primary wiring

PL-60-12-MU, Installation Guide, PS

Input: 100-277 / Output: 12 VDC

PRODUCT RETROFIT GUIDE

PAGE 5 OF 7

A Principal Industries Company

Cabinets and Channel Letters

Enclosure/Raceway Mount Power Supplies

Tools required Supplies required

Screwdriver, Drill, Wire Stripper, Silicone and Gun UL Listed PTLC Cable, Wire Nuts, #8 Panhead Screws

Make secondary connections:

Secondary output is 12VDC or 24VDC.

Secondary Class 2 Cables DO NOT require

conduit per NEC 2008 Articles 725.121-

130. Always seal wall penetrations

carefully to prevent water damage.

NOTE: Do not exceed 5A DC load for 12VDC or 4 A load for

24VDC. To minimize light loss it is recommended to split

the load equally in two parallel runs (2.5A @ 12VDC or 2.0A

@ 24VDC) of LED modules, or wire the secondary input to

both ends of the fully loaded 5A strand of LEDs

Mount power supply: Using a drill and

the #8 Panhead screws, mount the

power supply inside the channel letter,

inside the raceway, or in a separate UL

enclosure using the mounting tabs at

the bottom of the supply.

Make primary connection: A licensed

electrician is required in order to bring

conduit to the junction box and make

the primary connection.

Sign cabinet or channel letter

Power supply UL Listed

J-Box

Secondary output connection

Primary power

conduit

Wall penetration

(fill with silicone)

Power Supply:

Primary side:

AC/L (Black)

AC/N (White)

Secondary side:

V+ (Red)

V- (Black/Blue)

FG (Green)

NOTE: Operating temperature is -22º to 158º F (-30º to 70º C) (see de-rating chart at PrincipalSloan.com for higher temperature option), therefore it is recommended

that the power supplies are spaced at least 4" (102 mm) apart side-to-side, 2" (51 mm) end-to-end (some models have been approved for 2" (51 mm) and 1" (25 mm)

end-to-end), and not in secondary enclosure to ensure optimal ventilation (please see table for details). To ensure maximum lifetime of the power supply, it is highly

recommended that a photocell or timer be used to prevent operation during daylight hours. Do not use more modules than recommended on the product installation

guide. Total amperage should not exceed max. output current (full list on next page).

Installation guide, self-contained PS

Input: 100-277 VAC or 277-347 VAC / Output: 12 or 24 VDC

PRODUCT RETROFIT GUIDE

PAGE 6 OF 7

A Principal Industries Company

Cabinets and Channel Letters

Enclosure/Raceway Mount Power Supplies

NOTE: Do not insert Stik into existing sockets until ballast has been disconnected from mains and removed.

1: Turn off power from main lines. 2: Cut power and secondary lines to

the existing ballast and remove.

3: Remove old fluorescent lamps from

existing lamp sockets.

4: Insert Stik into lamp socket.

See depth chart to determine LED

direction. Depth Chart can be found at

PrincipalSloan.com

5: Using UL Listed 12-18 gauge hook-up

wire, connect gray wire (+) and white wire

(-) to the 12V power unit using wire nuts.

6: Connect hook-up wire to the

secondary output of the 12VDC power

supply.

Troubleshooting

• Check power to sign.

• Check power connection to the driver.

• Check polarity on the Direct Current side (Red+ / Black -).

• Check wire nut connections to each Stik.

New Construction Mounting Brackets

NOTE: Mounting brackets are available for new construction.

Use as a mounting base on each side of the cabinet.

This instruction sheet is meant to be used in accordance with all NEC and local

electrical codes. This document does not supersede any local, state, or national

regulations. For questions, please contact Principal Sloan at 325.227.4577 or visit

us on the web at PrincipalSloan.com

1: Mount base to each side

of the return.

2: Insert Stik onto threaded

base and adjust using wing

nut to desired position and

tighten.

Tighten wing

nut at each

end to adjust

height and

stabilize the

Stik.

LEDs may be pointed

to sign face or return

depending on depth

to face.

Rev B 2024-06-19

Customer service and technical support

PAGE 7 OF 7

principalsloan.com

325.227.4577

3490 Venture Dr., San Angelo, TX 76905

PRODUCT RETROFIT GUIDE

Cabinets and Channel Letters

A Principal Industries Company

E#341517 UL Recognized Principal Sloan LED Power Supplies

Model SKU Input voltage Input current

Output

voltage

Output

current Frequency Location rating

Energizer Series 20W

12VDC Power Supply

P-OH020-12-EC 90-305 VAC Max. 0.5 A 12 VDC 0-1.67 A 47-63 Hz Wet/Damp/Dry

Energizer Series 20W

24VDC Power Supply

P-OH020-24-EC 90-305 VAC Max. 0.5 A 24 VDC 0-0.833 A 47-63 Hz Wet/Damp/Dry

Energizer Series 60W

12VDC Power Supply

P-OH060-12-EC 90-305 VAC Max. 1.35 A 12 VDC 0-5 Amps 47-63 Hz Wet/Damp/Dry

Energizer Series 60W

24VDC Power Supply

P-OH060-24-EC 90-305 VAC Max. 1.35 A 24 VDC 0-2.5 Amps 47-63 Hz Wet/Damp/Dry

Energizer Series Threaded

100W 24VDC Power Supply

P-OH100-24-EC-T 90-305 VAC Max. 2.5 A 24 VDC 0-4 Amps 47-63 Hz Wet/Damp/Dry

Energizer Series Threaded

60W 12VDC Power Supply

P-OH060-12-EC-T 90-305 VAC

1.33 A/100 VAC,

0.65 A/230 VAC

12 VDC 0-5 Amps 47-63 Hz Wet/Damp/Dry

HE 120 W 12VDC Power Supply P-OH120-12-HE 120-277 VAC

1.2 A/120 VAC,

0.51 A/277 VAC

12 VDC 0.5-5.0 Amps 50-60 Hz Damp/Dry

HE 180 W 12VDC Power Supply P-OH180-12-HE 120-277 VAC 1.8-0.76 A 12 VDC

0.5-5.0 Amps

(per channel, 3-channel)

50-60 Hz Damp/Dry

HE 300 W 24VDC Power Supply P-OH300-24-HE 120-277 VAC 2.9-1.27 A 24 VDC

0.41-4.1 Amps

(per channel, 3-channel)

50-60 Hz Damp/Dry

HE 60 W 12VDC Power Supply

*

P-OH060-12-HE 110-277 VAC

0.61 A/100 VAC,

0.27 A/277 VAC

12 VDC 0.5-5.0 Amps 50-60 Hz Damp/Dry

HE 96 W 24VDC Power Supply

*

P-OH096-24-HE 110-277 VAC

0.98 A/100 VAC,

0.42 A/277 VAC

24 VDC 0.41-4.1 Amps 50-60 Hz Damp/Dry

Universal 100 W 24VDC

Micro-Driver Power Supply

P-OH100-24-MD 120-277 VAC

0.9 A/120 VAC,

0.39 A/277 VAC

24 VDC 0-4.0 Amps 50-60 Hz Damp/Dry

Universal 60 W 12VDC

Micro-Driver Power Supply

P-OH060-12-MD 100-277 VAC Max. 0.7 A 12 VDC 0-5.0 Amps 50-60 Hz Damp/Dry

Voltage Drop Chart

Voltage (VDC)

Current

(A)

Power

(W)

Wire Gauge

24 22 20 18 16 14 12 10 8 6 4 2

12

0.5 6 40 64 100 160 250 400 650 1000 1600 2550 4000 6500

1.0 12 20 32 50 80 125 200 325 500 800 1275 2000 3200

1.5 18 13 22 33 55 85 132 215 330 525 850 1400 2150

2.0 24 10 16 25 40 62 100 160 250 400 650 1000 1600

2.5 30 8 13 20 32 50 80 125 200 325 500 800 1290

3.0 36 7 11 17 26 42 66 110 165 265 425 675 1100

3.5 42 6 9 14 23 36 58 90 145 230 365 575 925

4.0 48 5 8 13 20 32 50 78 125 200 320 500 800

4.5 54 4 7 11 18 28 45 70 110 175 280 450 720

5.0 60 4 6 10 16 25 40 65 100 160 255 400 640

24

0.5 12 80 128 200 320 500 800 1300 2000 3200 5100 8000 13000

1.0 24 40 64 100 160 250 400 650 1000 1600 2550 4000 6400

1.5 36 26 44 66 110 170 264 430 660 1050 1700 2800 4300

2.0 48 20 32 50 80 124 200 320 500 800 1300 2000 3200

2.5 60 16 26 40 64 100 160 250 400 650 1000 1600 2580

3.0 72 14 22 34 52 84 132 220 330 530 850 1350 2200

3.5 84 12 18 28 46 72 116 180 290 460 730 1150 1850

4.0 96 10 16 26 40 64 100 156 250 400 640 1000 1600

NOTE: All distance denoted in feet.