Guidelines for Design of

Small Public Ground Water

Systems

Division of Drinking and Ground Waters

June 2023

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 2 of 77

Foreward

This publication has been prepared as a guide for professional engineers and water supply specialists engaged in

the design or development of small public water systems (non-community and communities serving less than

500 service connections) using only ground water, which is not required to treat for a primary contaminant with

a maximum contaminant level or a contaminant with a health advisory level (HAL). The objective here is to

ensure that new or substantially modified public water system facilities, such as those for small villages,

factories, mobile home parks, office buildings, restaurants, condominiums, schools, churches, hospitals,

campgrounds, resorts, gas stations, nursing homes, golf courses, and the like will be capable of producing an

adequate supply of potable water in compliance with applicable regulations.

The following table may be used as a guide for the applicability of design guidance:

Public Water System (PWS) Description (ground water only)

Guidelines for Design of

Small Public Water

Systems

Recommended

Standards for

Water Works

All Transient PWS

X

Nontransient PWS not required to treat for a primary contaminant or

a contaminant with a HAL per OAC 3745

X

Nontransient PWS required to treat for a primary contaminant or a

contaminant with a HAL per OAC 3745

X

Community < 500 not required to treat for a primary contaminant or a

contaminant with a HAL per OAC 3745

X

Community < 500 required to treat for a primary contaminant or a

contaminant with a HAL per OAC 3745

X

Community > 500 required to treat for a primary contaminant or a

contaminant with a HAL per OAC 3745

X

The purpose of this manual is to present the requirements and procedures necessary to develop an approved

water supply system where connection to an existing public water system cannot be made at reasonable cost.

This publication includes treatment design criteria for iron, manganese, and hardness removal, which are not

required as part of OAC 3745.

The design of water systems using surface water or ground water under the direct influence of surface water is

beyond the scope of this manual. Refer to the latest edition of “Recommended Standards for Water Works” for

design criteria.

The requirements, criteria, and procedures described in this publication represent current practices of the Ohio

Environmental Protection Agency (Ohio EPA). They are subject to change whenever in the judgment of the

Agency such a change will be more effective in fulfilling its responsibility under the law.

NOTE: For sewage, a similar publication entitled, “Sewage: Collection, Treatment & Disposal Where Public

Sewers Are Not Available” may be obtained from Ohio EPA's Division of Surface Water.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 3 of 77

Table of Contents

Foreward ...................................................................................................................................................................................... 2

Table of Abbreviations ................................................................................................................................................................. 5

Policy Statement on Infrastucture Security for Small Public Water Systems .............................................................................. 6

Statement on Alternative Water Treament Processes ................................................................................................................ 6

General .................................................................................................................................................................................... 6

Chapter 1 - Definitions ................................................................................................................................................................. 7

1.0 Public Water System (PWS) ........................................................................................................................................ 7

1.1 Types of Public Water Systems .................................................................................................................................. 7

Chapter 2 - Procedure for Establishing a Small Public Ground Water System ............................................................................ 8

2.0 General ....................................................................................................................................................................... 8

2.1 Plan Submittal Requirements ..................................................................................................................................... 8

2.2 Connection to an Existing Approved System.............................................................................................................. 9

2.3 Development of an Approved Ground Water System ............................................................................................... 9

2.4 Develop an Approved Storage System Using Hauled Water .................................................................................... 10

2.5 Plan Submittal and Information Required on Plans ................................................................................................. 10

Chapter 3 - Source ..................................................................................................................................................................... 11

3.0 General ..................................................................................................................................................................... 11

3.1 Availability of Well Water......................................................................................................................................... 11

3.2 Quality of Water ....................................................................................................................................................... 11

3.3 Well Site Approval .................................................................................................................................................... 12

3.4 Basis of Design .......................................................................................................................................................... 16

3.5 New Well Construction ............................................................................................................................................ 22

3.6 Casing Extensions ..................................................................................................................................................... 23

3.7 Approval of Existing Wells as Public Water Supply Wells ........................................................................................ 25

3.8 Pumping Tests .......................................................................................................................................................... 26

3.9 Reporting .................................................................................................................................................................. 28

3.10 Disinfection of Wells ................................................................................................................................................ 30

3.11 Sealing of Wells That Are No Longer Used or Needed ............................................................................................. 31

3.12 Standards ................................................................................................................................................................. 32

Chapter 4 - Treatment ............................................................................................................................................................... 32

4.0 General ..................................................................................................................................................................... 32

4.1 Detail Plan Approval Exemptions ............................................................................................................................. 32

4.2 Disinfection .............................................................................................................................................................. 32

4.3 Iron and Manganese Removal .................................................................................................................................. 36

4.4 Cation Ion Exchange Softening ................................................................................................................................. 46

4.5 Additional Treatment Methods ................................................................................................................................ 47

4.6 Corrosion Control ..................................................................................................................................................... 49

4.7 Waste Disposal ......................................................................................................................................................... 49

Chapter 5 - Storage .................................................................................................................................................................... 52

5.0 General ..................................................................................................................................................................... 52

5.1 Clearwell Storage ..................................................................................................................................................... 52

5.2 Ground Level Storage ............................................................................................................................................... 52

5.3 Elevated Storage ...................................................................................................................................................... 53

5.4 Hydropneumatic Tanks ............................................................................................................................................ 54

5.5 Constant Pressure Systems ...................................................................................................................................... 54

Chapter 6 - Distribution ............................................................................................................................................................. 55

6.0 Plan Submittal .......................................................................................................................................................... 55

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 4 of 77

6.1 Standards ................................................................................................................................................................. 55

6.2 Backflow Prevention and Cross-Connection Control ............................................................................................... 57

APPENDIX A - Example Well Site Map ....................................................................................................................................... 58

APPENDIX B - Suggested Water Usage Guide ........................................................................................................................... 60

APPENDIX C - Sample ODNR Well Log and Drilling Report ........................................................................................................ 63

APPENDIX D - Well Construction Worksheet for Existing Wells ................................................................................................ 65

APPENDIX E - 24-Hour Pumping Test Report ............................................................................................................................. 67

APPENDIX F - Sample ODNR Water Well Sealing Report ........................................................................................................... 73

APPENDIX G - Hauled Water System – Design Requirements ................................................................................................... 75

Figures

Figure 1 - Well Isolation Radius ................................................................................................................................................. 13

Figure 2 - Determining Storage Requirements .......................................................................................................................... 18

Figure 3 - How to Calculate Storage Requirements ................................................................................................................... 19

Figure 4 - Well Profile and Construction Form .......................................................................................................................... 24

Figure 5 - Disinfection ................................................................................................................................................................ 34

Figure 6 A & B - Disinfection with Cation Exchange Softening .................................................................................................. 35

Figure 7 - Iron Removal .............................................................................................................................................................. 37

Figure 8 - Iron and Manganese Removal (Revised) ................................................................................................................... 38

Figure 9 - Iron Removal and Ion Exchange Softening ................................................................................................................ 38

Figure 10 - Ion Exchange Softening............................................................................................................................................ 39

Tables

Table 1 - General Media Guidance ............................................................................................................................................ 42

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 5 of 77

Table of Abbreviations

ANSI American National Standards Institute

ASME American Society of Mechanical Engineers

ASTM American Society of Testing and Materials

AWWA American Water Works Association

BMP Best Management Practices

CWS Community Water System

NPDES National Pollutant Discharge Elimination System

NSF National Sanitation Foundation

NTNC Nontransient Noncommunity Water System

OAC Ohio Administrative Code

ODNR Ohio Department of Natural Resources

ORC Ohio Revised Code

PE Professional Engineer

PTI Permit to Install

PUCO Public Utilities Commission of Ohio

PVC Polyvinyl Chloride

PWSID Public Water System Identification Number

TNC Transient Noncommunity Water System

WSC Water System Council

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 6 of 77

Policy Statement on Infrastucture Security for Small Public Water

Systems

Recent events in the United States and abroad have made it clear that increased security for public water systems

is imperative. Review of public water system security infrastructure and practices has shown an industry-wide

vulnerability to intentional acts of vandalism, sabotage and terrorism. Protection from these types of threats

must be integrated into all design considerations. Security measures are needed to help ensure that public water

suppliers attain an effective level of security, no matter how small the water system. Design considerations need

to address physical infrastructure security and facilitate security related operational practices and management

controls. All public water supplies need to identify and address security needs in design and construction for

new projects and for retrofits of existing drinking water systems.

Appropriate design measures for small water systems include the following:

A. Controlling access and installing fences and locks for all drinking water treatment facilities and

vulnerable areas (e.g., wellheads, hydrants, manholes, pumphouses, storage tanks).

B. Installing locks on all entry gates and doors and installing alarms to indicate unauthorized entry. Do not

leave keys in equipment or vehicles at any time.

C. Installing adequate lighting around wells, pumphouses, treatment facilities and parking areas.

D. Locking monitoring wells, securing vents by moving them inside or providing vandal resistant screens

and fencing.

E. Cyber security should be considered for all remotely controlled equipment, ensuring software is up to

date when applicable.

Statement on Alternative Water Treament Processes

General

This revision to the “Guidelines for Design of Small Public Ground Water Systems,” also referred to as the

“Greenbook,” updates Ohio EPA’s increasing familiarity with newer filter media products. It is recognized the

list of media is not all-inclusive and is dynamic. Other processes are understood to exist that may be “emerging”

or “alternative” treatment processes at this time. Alternative water treatment processes involve technologies or

proprietary products not frequently seen in small public water system design. Although not covered in this

publication, Ohio EPA recognizes many of these treatment processes have been successfully used in other

settings and will evaluate these processes at public water systems on a case-by-case basis.

Ohio EPA is in the process of developing guidance that describes in more detail the testing requirements for

alternative water treatment processes. Testing requirements can vary from minor sample collection prior to

design (to validate raw water quality applicability), to a demonstration study, up to more thorough testing on a

pilot plant basis for a sufficient time to verify satisfactory performance.

Ground water treatment plants with loading rates higher than described in this manual may be acceptable on a

case-by-case basis. It will be necessary to demonstrate to Ohio EPA that the desired water quality can be

produced under varying raw water conditions and system flow demands.

Ohio EPA considers alternative ground water treatment processes to include, but not be limited to, the following:

membrane filtration, reverse osmosis, anion exchange, ozonation, ultraviolet light inactivation, carbon filtration

adsorption, activated alumina and iron-based media. Information on pilot plant study requirements is available

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 7 of 77

on the Ohio EPA Division of Drinking and Ground Waters website. You can also contact Ohio EPA Central Office

or your District Office for more information.

Chapter 1 - Definitions

1.0 Public Water System (PWS)

A public water system as defined in Ohio Administrative Code (OAC) 3745-81-01, is a system that provides water

for human consumption through pipes or other constructed conveyances, if such systems have at least 15 service

connections or regularly serves an average of at least 25 people at least 60 days a year.; or is any water supply

system serving an agricultural migrant labor camp as defined in Section 3733.41 of the Ohio Revised Code.

1.1 Types of Public Water Systems

1.1.1 Community Water System (CWS):

A CWS has at least 15 service connections used by year-round residents or regularly serves at least

25 year-round residents.

Examples of a CWS may include, but are not limited to, cities, villages, nursing homes and mobile

home parks.

1.1.2 Nontransient Noncommunity Water System (NTNC):

A NTNC serves at least 25 of the same persons at least 6 months per year.

Examples of a NTNC may include, but are not limited to, schools, daycare centers, factories and

other places of employment.

1.1.3 Transient Noncommunity Water System (TNC):

A TNC serves an average of at least 25 persons per day for at least 60 days per year.

Examples of a TNC may include, but are not limited to, campgrounds, churches, restaurants and

rest areas.

1.1.4 Agricultural Migrant Labor Camp:

Any water supply system serving an agriculture migrant labor camp, as defined in Section 3733.41

of the ORC.

1.1.5 Exempt Water System:

To be exempt from Ohio EPA Drinking Water Regulations (ORC Section 6109.02) a system must

meet all of the following conditions:

1.1.5.1 Consist only of distribution and storage facilities and does not have any collection and

treatment facilities.

1.1.5.2 Obtain all of its water from, but is not owned or operated by, a public water system.

1.1.5.3 Does not sell water to any person as determined by the director.

1.1.5.4 Is not a carrier which conveys passengers in interstate commerce, e.g., airline, railroad,

bus line, boat line, etc.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 8 of 77

Chapter 2 - Procedure for Establishing a Small Public Ground Water

System

2.0 General

Connection to an existing approved public water system should be given primary consideration. A ground water

system may be developed if connection to an approved existing system is impractical. Alternatively, a hauled

water system may be considered, (see Section 2.4). The owner must be aware that hauled water systems are

more susceptible to interruption of supply and may be more susceptible to contamination.

2.1 Plan Submittal Requirements

2.1.1 According to OAC 3745-91-05 (A):

No person shall begin construction or installation of a public water system or make a substantial

change in a public water system, or operate a public water system, until plans have been approved

by the Director of Ohio EPA.

Upon receipt of a proper application, the Director shall consider the need for compliance with

requirements of the Safe Drinking Water Act, and generally accepted standards for the construction

and equipping of water systems and shall issue an order approving or disapproving such plans. In

granting an approval, the Director may stipulate conditions designed to ensure that the system will

be able to meet the requirements of ORC Chapter 6109 and rules adopted under it.

2.1.2 According to OAC Rule 3745-91-01(C):

“Substantial change” means any change that affects isolation, capacity, flows, water quality, source,

distribution or treatment.

Substantial change shall include, but not be limited to, the following:

1. For distribution systems: new waterlines; replacement waterlines that change in size,

alignment or material; new tanks; modification in storage; new booster stations; changes in

pump capacity and auxiliary power. Some waterline replacements are exempt from detail

plan approval in accordance with OAC 3745-91-02.

2. For water sources: any new source or alteration in source, including connection to another

source or distribution system; any alteration in collection facilities or equipment.

3. For treatment facilities: new treatment processes, including facilities, equipment or

chemicals; changes in chemical feed capacity, feeder type, application points or sequence;

modifications to or removal of treatment processes, equipment or chemicals.

Substantial change shall not include the following:

1. For distribution systems: waterline cleaning, re-lining, repairs or like-kind replacement;

service connections; and tank maintenance.

2. For water sources: like-kind pump replacement.

3. For treatment facilities: like-kind replacement of components, as defined in OAC 3745-91-

01. If there are questions regarding if the proposed replacement meets the design criteria

previously approved or if proposed treatment meets the definition of like-kind

replacement, contact the Ohio EPA district office.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 9 of 77

2.2 Connection to an Existing Approved System

2.2.1 Contact existing public water system(s) within an economical piping distance.

2.2.2 Determine what needs to be done to facilitate the connection to the existing system.

2.2.3 If a waterline needs to be extended to your property, plans for any new water line from the water

system to the master meter must be approved by Ohio EPA prior to construction, and the new water

lines must be owned by the existing water system before they are placed in service. A service

connection to a building or residence from the PWS owned waterline does not require a submission

of detail plans to Ohio EPA.

2.3 Development of an Approved Ground Water System

Where there is no existing public water system within economical piping distance, give consideration to the

development of a ground water system.

2.3.1 Contact the appropriate District Office of Ohio EPA’s Division of Drinking and Ground Waters to

request an evaluation of a proposed well site and to establish the requirements, design criteria and

responsibilities involved. (See the map at the end of this publication, which includes Ohio EPA

District addresses and telephone numbers.)

2.3.2 Submit a completed well site application to the District Office. The application can be found on the

Ohio EPA website.

2.3.3 Obtain a well site inspection and site approval from the director. The well site approval is valid for

two years.

2.3.4 Arrange with an Ohio EPA certified laboratory for analysis of the required parameters for new wells

after the well has been drilled and developed. A list of certified laboratories can be found on the Ohio

EPA website. Allow at least six weeks for analysis of samples. A list of required parameters

(Parameters Required for Complete Well Analysis) is included in OAC Rule 3745-9-09.

2.3.5 The well must be constructed and grouted in accordance with the construction and grouting

standards prescribed in OAC Chapter 3745-9. All wells must be grouted, including those drilled by the

cable tool method. Well construction standards can be found in Section 3.5, with requirements

specific to PVC casing noted in item 3.5.3-13. Be advised that the Ohio Department of Health Private

Water System Program maintains a registry of drilling contractors who operate in the state of Ohio.

2.3.6 Perform a pumping test (refer to Section 3.8) and collect the required samples at the conclusion.

2.3.7 Submit the pumping test and sample analyses, prior to plan approval, to the District Office for

evaluation and information regarding the treatment processes required for your proposed system

based on the sample analyses.

2.3.8 Have a professional engineer or a water supply specialist knowledgeable in design prepare plans for

the system, covering well construction, treatment, storage and distribution.

2.3.9 Submit detail plans. Construction of the treatment, storage and distribution system must not begin

until the formal approval letter is received from the director.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 10 of 77

2.4 Develop an Approved Storage System Using Hauled Water

Hauled water systems are not recommended for community public water systems. Consult the District Office to

determine whether or not the hauled water system will be exempt from Ohio EPA regulation (see Section 1.1.5).

If the hauled water system is not exempt, plans will be required (see Appendix G ). If the hauled water system

will be exempt, the required health department and plumbing permits must still be obtained.

2.5 Plan Submittal and Information Required on Plans

Detail plans are required for a proposed water system. These should be prepared by a professional engineer or a

water supply specialist knowledgeable in system design in accordance with OAC 3745-91-03. Plans should be

submitted at least 60 days prior to the desired approval date. These plans shall contain the following, where

applicable:

2.5.1 A site map (Appendix A), drawn to scale, showing existing and/or proposed:

2.5.1.1 Property lines, ownership of land, and land use of surrounding properties.

2.5.1.2 Outlines of buildings, including those relevant to the project which are located on adjacent

properties.

2.5.1.3 Water system location.

2.5.1.4 Sewerage system location.

2.5.1.5 Well site(s) with isolation radius (radii), and showing any potential sources of contamination

and areas owned or having sanitary protection through recorded easements.

2.5.1.6 Nearby streets, driveways, and enough boundary information to locate the project.

2.5.1.7 Any expected future expansion of the project.

2.5.1.8 North arrow to show orientation.

2.5.1.9 Elevations pertinent to the design.

2.5.1.10 Location of water mains, pump stations, raw water intakes, water plant, waste disposal

facilities, and other existing or proposed parts of this system.

2.5.1.11 Locations of potential contaminant sources within drinking water source protection area,

both the inner management zone and five year time of travel area.

2.5.2 Details showing conformance with standards and requirements for:

2.5.2.1 Source (Chapter 3)

2.5.2.2 Treatment (Chapter 4)

2.5.2.3 Storage (Chapter 5)

2.5.2.4 Distribution (Chapter 6)

2.5.3 The application for detail plans on the portal replaces the Water Supply Data Sheet. Following

submittal of plans, the submitter is emailed an invoice for the plan review fee. Additional

information is located on the Ohio EPA website under the Division of Drinking and Ground Waters

website, engineering and plan approval page.

2.5.4 Specifications, project summary sheets and supporting data (e.g., well log, pumping test, etc.)

2.5.5 Other letters as appropriate such as PUCO certificate of convenience and necessity, if applicable or

additional documentation required for obtaining Water Supply Revolving Loan Account (WSRLA)

funding.

2.5.6 A title page showing, at a minimum:

2.5.6.1 The owner’s name and address.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 11 of 77

2.5.6.2 The official name and address of the public water system.

2.5.6.3 The title of the project being submitted for review.

2.5.6.4 The public water system identification number (PWSID).

2.5.6.5 PE stamp (as required by ORC Section 4733.17 and OAC 3745-91-03).

2.5.6.6 Signature of water system owner approving the plans or a signed submittal letter from the owner

or the owner’s representative, requesting approval of the plans.

2.5.7 An asset management program (AMP) is required for new community and non-transient non-

community public water systems. The AMP must include the applicable requirements as defined in

OAC Chapter 3745-87. An AMP is also required for any existing system receiving State Revolving Loan

Funding or Drinking Water Emergency Loan Funding.

Chapter 3 - Source

3.0 General

This section overviews requirements for developing a groundwater supply source. The engineer or water system

specialist responsible for designing the groundwater system must demonstrate an adequate quantity of safe

drinking water will be available to consumers. Approval of a groundwater source will be contingent on the

quality and quantity of water supplied from the proposed well(s).

Metering of the water shall be provided for all community water systems and recommended for all

noncommunity water systems.

3.1 Availability of Well Water

The availability of an adequate well water supply is a major consideration in the selection of a well site.

Information on the availability of ground water can be obtained from the Ohio Department of Natural

Resources, Division of Soil and Water Resources, Ground Water Mapping and Technical Services Section (Tel:

614-265-6747).

3.2 Quality of Water

3.2.1 Microbiological Quality

Before any new, reconditioned or modified well is placed into potable service, the well must be

disinfected in accordance with Section 3.10. Total chlorine shall be tested and the results of the test

noted on the sample submission form. Total chlorine shall be undetectable prior to sampling for

microbiological samples. Two consecutive total coliform negative microbiological samples taken at

least 30 minutes apart shall be taken from the well. Analysis shall be performed by an Ohio EPA

certified laboratory. Ohio EPA certified laboratory list can be found on the Ohio EPA Division of

Environmental Services webpage. Additional monitoring may be required if the grouting of the well

is questionable.

If a well cannot achieve negative (safe) bacteriological samples, it may require treatment which is

beyond the scope of this manual. Contact your District Office for further guidance.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 12 of 77

3.2.2 Chemical and Radiological Quality

Every proposed ground water source must be examined for applicable chemical and radiological

characteristics by analysis of a representative sample in a laboratory certified by Ohio EPA. Note if

contaminants are detected, then re-sampling may be required to confirm the results.

The samples for laboratory analysis must be collected at the conclusion of the pumping test

procedures and prior to initiation of the recovery period. Ohio EPA can advise on whether the well

can be approved, and on methods and types of treatment required on the basis of the results of

required analyses (see OAC 3745-9-09 (C)). Wells, with sample results exceeding maximum

contaminant levels (MCL), may require treatment beyond the scope of this manual. Contact District

Office for further guidance.

3.2.3 Secondary Standards

The presence of contaminants above the secondary maximum contaminant level (SMCL) may require

treatment.

Treatment may be required for community and non-transient non-community water systems to

remove excessive levels of iron and manganese, which cause staining of laundry and plumbing

fixtures and which give the water a mineral taste (see Chapter 4). Abnormally high amounts of

chlorides, sulfates and total dissolved solids can also make water objectionable for drinking. High

levels of sodium are a concern when serving communities with sodium restricted diets. Community

PWSs having sources with elevated levels, above 20 mg/L, of sodium are strongly encouraged to

ensure the susceptible population is informed and educated.

3.3 Well Site Approval

3.3.1 Requirements

Sites for public water supply wells must be approved by Ohio EPA before the wells are drilled or

when an existing system is designated a public water system. Contact the District Office for more

information.

3.3.2 Submittals

Submit a completed well site application, available on the Ohio EPA website, to the District Office.

NOTE: Refer to Appendix B for suggested water usage guide. Alternative methods of obtaining water

usage such as fixture counts or historical flow and pressure data may be used in certain

circumstances as described in Section 3.4.

3.3.3 Site Visit

The District Office will review the well site application and contact you to arrange for a site visit. A

representative of the system, and the selected well driller, should be present during this visit. Several

items may be discussed in the field including, but not limited to:

1. Sanitary control of isolation zone surrounding the proposed well. (See Section 3.3.5).

2. Known or suspected water quality issues.

3. Detail plan preparations.

4. Source water protection.

5. Certified laboratories for analysis.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 13 of 77

The District Office will be available to answer questions the system representative may have

regarding the well site.

3.3.4 Site Evaluation

The owner will receive a letter from the director either approving or denying the site for the

proposed project. Additional requirements may be stipulated in the well site approval letter.

3.3.5 Isolation Standards and Well Siting Criteria

A proposed public water system well shall be located the maximum practical distance from potential

or known contamination. Unless local conditions dictate greater distances, approval of each well site

will be based on compliance with the following isolation radii and well siting criteria:

Estimated Average Daily

Water Usage (Q)

Minimum Isolation Radius from

Sources of Possible Contamination

0-2,500 gpd

2,501-10,000 gpd

10,001-50,000 gpd

Over 50,000 gpd

50 feet

(Square Root of Q) feet

(50 + Q/200) feet

300 feet

Well isolation radius will be determined in the Director’s well site approval letter and finalized in

the Director’s plan approval letter. The isolation radius can only be adjusted with an updated

Director’s plan approval letter.

Figure 1 - Well Isolation Radius

Use Figure 1 to calculate the required isolation radius. Normally, the required isolation distance

shall be rounded up to the nearest five feet.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 14 of 77

Potential sources of contamination shall not be constructed or placed within the sanitary isolation

radius of a public water system well.

Where geological factors warrant less isolation from sources of contamination, a qualified ground

water professional’s report to that effect, together with a statement of protective measures, may be

accepted.

Where fractured bedrock or extremely porous subsoil extends to or near the surface of the ground

or where poor drainage or other unfavorable conditions are encountered, greater isolation distance

or treatment as a surface water supply may be required.

The owner of the well shall own all of the land or obtain a sanitary easement or lease of the sanitary

isolation radius of the well. Land application of sludge or manure shall not be applied within

easements. The easement or lease must meet specifications set forth in OAC Rule 3745-9-04 and

shall be recorded with the County Recorder’s Office. Any proposed change in land use within the

isolation radius requires consultation with Ohio EPA. Additionally, if proposing to use fertilizers,

herbicides, or pesticides within an easement, please consult Ohio EPA to ensure the methods used

to apply and select chemicals adequately prevent contaminants from infiltrating the well; Ohio EPA

may require additional monitoring based upon circumstances.

The well shall be adequately protected from physical damage. The installation of barriers may be

required to protect the well from vehicular traffic or other inadvertent damage.

A public water system well shall be located at least:

1. Ten feet from the foundation of any building, except within a pumphouse.

2. Fifty feet from streams and lakes.

3. Three hundred feet from a human or animal waste management facility.

4. Three hundred feet from a land application area, stockpile, storage or staging area.

5. One hundred feet from a land application area field if the waste is injected or three hundred

feet if the waste is surface applied but in no case within the sanitary isolation radius of the

well.

6. Three hundred feet from a soil absorption system handling more than ten thousand gallons

per day.

7. One thousand feet from a landfill or monofill.

8. Five hundred feet from a construction and demolition debris facility.

9. Outside of a floodway unless prior approval is obtained from the director. Casing must

terminate at least 3 feet above the 100 year flood plain level. Wells located within wetlands

may require additional permits. Contact the Division of Surface Water for more information.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 15 of 77

A public water system well used by a community or nontransient noncommunity public water

system shall be located such that the following are not located within the proposed well's inner

management zone as determined by the system’s Source Water Assessment and Protection Plan

(SWAP):

1. Human or animal waste management facility, except a well that is used by the facility.

2. Soil absorption system handling more than ten thousand gallons per day in an area where

the Ohio EPA has determined the aquifer has a high susceptibility to contamination.

3. Land application stockpile, storage or staging area where the Ohio EPA has determined the

aquifer has a high susceptibility to contamination.

A public water system well shall be sited such that no landfill or monofill is located within the

proposed well's drinking water source protection area (5 year time-of-travel).

Other possible sources of contamination must be brought to the attention of the District

Representative and their potential effect on the proposed well evaluated by the District

Representative. Possible sources of contamination include, but not limited to:

1. Grossly contaminated (chemical or bacteriological) rivers, streams or drainage ditches.

Rivers, streams and ditches are not considered as possible sources of contamination.

2. Sewers that carry sanitary or chemical waste, or storm water or field drainage tiles.

3. Septic tanks, leaching wells or beds, privies, cesspools, surface or subsurface sand filters,

sewage force mains, or sewage treatment plants.

4. Livestock holding areas, barnyards or feed lots for which feed is brought in from another

source. Pasture land is not considered as a possible source of contamination.

5. Railroad right-of-ways in which spills may have occurred or defoliant agents may have been

applied.

6. Waste or product storage tanks (above or below ground), oil and gas production wells,

mining operations, landfills, disposal areas old or new, demolition fill areas, pipelines (gas

mains, oil mains, etc.), manufacturing facilities in the proximity of the proposed well field,

and abandoned wells which are not properly sealed.

3.3.6 Sanitary Sewers in Well Field Areas

The current Ohio EPA policy regarding sanitary sewers in a well field area is as follows:

3.3.6.1 Sanitary and combined sewers are not acceptable in well field areas; however, they may be

permitted under exceptional and unavoidable circumstances. Pressure sewers and manholes

shall not be permitted under any circumstances. In any case, sanitary and combined sewers

and associated manholes shall not be located closer than 50 feet or one-third of the isolation

radius, whichever is greater, approved for that well or specified by the Division of Drinking

and Ground Waters guidelines. Gravity sewer laterals should meet the 50 feet isolation

radius.

3.3.6.2 The Division of Drinking and Ground Waters may require quarterly or monthly bacterial and

nitrate/nitrite monitoring of each well when sanitary sewers are located within the isolation

radius.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 16 of 77

3.3.6.3 A best management practices (BMP) program shall be implemented for sanitary sewers or

combined sewers within well field areas. Provisions shall be made for periodically pressure

testing the sewer. The sewers shall be pressure tested at a frequency determined by the

District Office, at a minimum of every five years.

3.3.6.4 Where sewers are being installed, the sewer materials shall be appropriate pressure rated

pipe and shall be pressure tested to ensure water tightness.

3.4 Basis of Design

3.4.1 Requirements

The primary well system must be capable of providing an adequate supply of water during normal

and peak usage periods. In addition, standby or alternate sources may be required in case of

emergency, pump failure, etc., as described in Section 3.4.3.

Calculate the average daily, peak daily, and peak hourly demands using factors not less than those

shown below:

1. Average Daily Demand = The estimated average daily water demand shall be determined by

using either the table provided in Appendix B or at least one year of historical water use.

Average Daily Demand may be determined by less than a year of historical data,

incorporating a safety factor. Contact your District Office Engineering Section with regard to

determining the safety factor for your system.

2. Peak Daily Demand = Average Daily Demand x 2.0, unless a lower peak demand factor is

supported by at least three years of historical daily flow data using the highest peak day to

average day ratio for the period of record.

3. Peak Hourly Demand = Average Daily Demand x 10*

(* Other sizing or design methods, such as fixture counts, conforming to documented

engineering practice standards are also acceptable alternatives. A lower peak hourly demand

factor must be supported by at least one year of continuous flow and pressure data).

Note: The capacity of the design pump cannot exceed the pumping test rate. See Section 3.8

for pumping test information.

3.4.2 Procedure

3.4.2.1 Drill Well: After the well site approval letter has been received (Section 3.3), the proposed

well may be drilled. Only water system contractors holding a valid registration from the Ohio

Department of Health may drill a well or install a pitless adapter or pitless unit for a public

water system well.

3.4.2.2 Test Pump: The well shall be pump tested to determine its capacity and to obtain water

quality samples as required. Air pumping or bailing is generally not acceptable for this test.

Static and pumping water levels and recovery rates shall be measured and recorded. See

Section 3.8 for pumping test report requirements.

3.4.2.3 Alternative: If the well does not have sufficient capacity to meet the standards of 3.4.3,

outlined below, the owner shall contact the District Office for assistance.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 17 of 77

3.4.3 Standards

3.4.3.1 All new community water systems and noncommunity water systems with a consumption

exceeding 50,000 gpd or with a population of 500 or greater shall be capable of meeting peak

demand with the largest well out of service. Existing community water systems with only one

fully functional well will be required to have two or more wells sized in accordance with

Section 3.4.3.2 when the existing well fails or cannot substantially meet peak demand, or

when the system demand causes pressure in the distribution system to fall below 35 psi. An

acceptable alternative to a redundant well would be an emergency connection to another

public water system with adequate capacity to meet peak demand.

3.4.3.2 Well Field and Treatment Capacity: The capacity of the wells, well pumps and treatment

components in a hydropneumatic pressure system must be sufficient to produce water at a

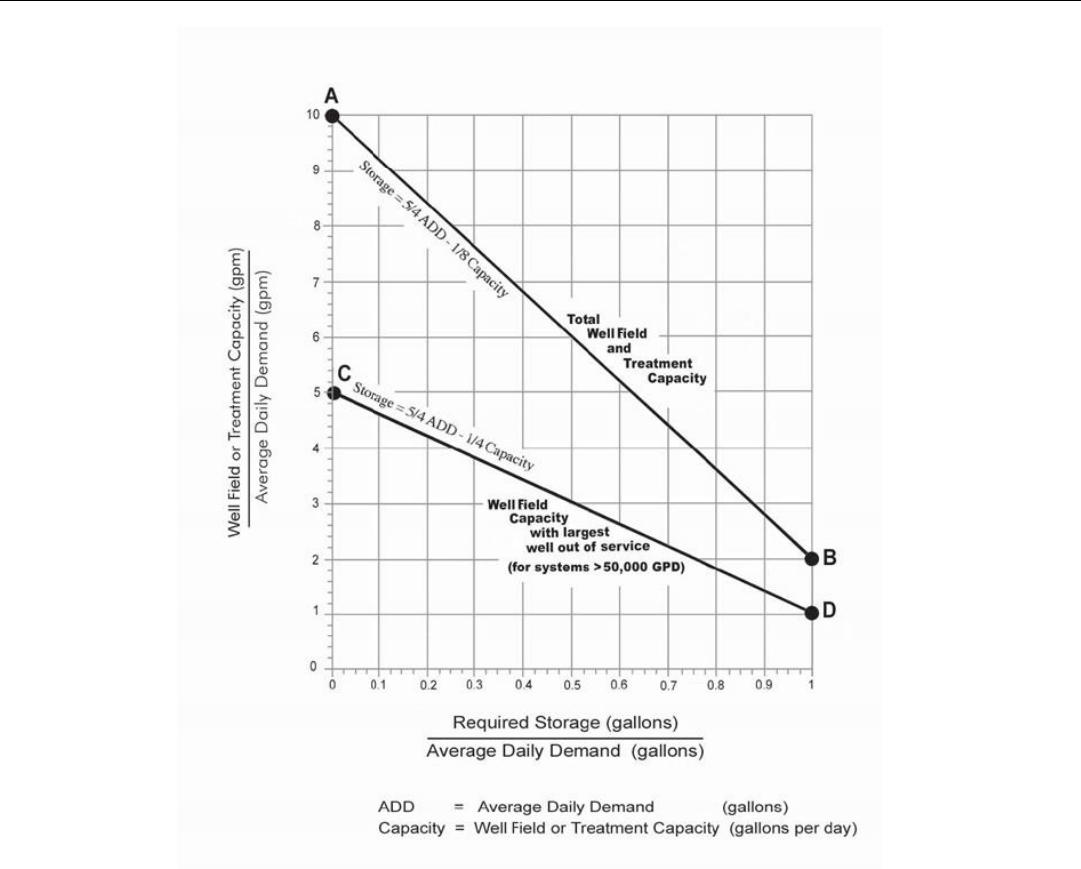

rate that is ten times the average daily water demand (See Figure 2, point “A”) or approved

alternative peak hourly flow rates. Where the aquifer cannot support this withdrawal rate, a

storage tank with high service pumps may be used to meet this peak requirement, provided

that the wells, well pumps and treatment components are able to produce water at a rate that

is twice the average daily water demand. (See Figure 2, point “B”. At point “B”, one day’s

storage is required.) Please note that, at a minimum, the total well field capacity must meet

the peak daily demand (twice the average daily water demand).

In addition, the wells, well pumps and treatment components in a hydropneumatic pressure

system using over 50,000 gpd must be sufficient to produce water at a rate that is five times

the average daily water demand with the largest well or treatment unit out of service (See

Figure 2, point “C”). Where the reduced well field cannot support this withdrawal rate, a

storage tank with high service pumps may be used to meet this peak requirement, provided

that the reduced well field is able to produce water at rate that is at least equal to the average

daily water demand. (See Figure 2, point “D”. At point “D”, one day’s storage is required.)

Please note that, at a minimum, the reduced well field capacity must meet the average daily

water demand. If withdrawal is anticipated to be greater than 100,000 gallons per day, then

PWS should contact Ohio Department of Natural Resources on permitting requirements.

Figure 2 can be used to determine storage requirements. A sample problem is provided

following the graph (Figure 3). The example is solved by utilizing the graph and storage

equations. Alternative methods for estimating storage requirements may be submitted for

consideration.

Water usage values are provided in Appendix B as an aid to calculate average daily water

demand.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 18 of 77

Figure 2 - Determining Storage Requirements

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 19 of 77

Figure 3 - How to Calculate Storage Requirements

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 20 of 77

NURSING HOME

Well #1 =

175 gpm

455 patients @ 150 gpd*

=

68,250 gpd

Well #2 =

50 gpm

15 resident employees @ 100 gpd

=

1,500 gpd

Well #3 =

50 gpm

45 non-resident employees @ 50 gpd*

=

2,250 gpd

Well #4 =

25 gpm

72,000 gpd

(50 gpm)

Total =

300 gpm

Ratio #1

=

Total Well field Capacity

=

300 gpm

=

6

Average Daily Demand

50 gpm

Ratio #2

=

Well field Capacity with Largest Well Out-of-Service

=

125 gpm

=

2.5

Average Daily Demand

50 gpm

From the Graph:

Required Storage (gallons)

= 0.62

Average Daily Demand (gallons)

Therefore:

Required Storage = 0.62 x Average Daily Demand = 0.62 x 72,000 gallons = 44,640 gallons

*values obtained from water usage table in B

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 21 of 77

Example (solve by using the equations)

NURSING HOME

Well #1

=

175

gpm

=

252,000

gpd

455 patients @ 150 gpd*

=

68,250

gpd

Well #2

=

50

gpm

=

72,000

gpd

15 resident employees @ 100 gpd*

=

1,500

gpd

Well #3

=

50

gpm

=

72,000

gpd

45 non-resident employees @ 50 gpd*

=

2,250

gpd

Well #4

=

25

gpm

=

36,000

gpd

Total

72,000

gpd

Total

=

300

gpm

=

432,000

gpd

Total

=

125

gpm

=

180,000

gpd

(without largest well)

Total Well field and Treatment Capacity

(Equation #1)

Storage Requirement

=

5/4 x ADD – 1/8 x capacity

(5/4) (72,000) – (1/8)(432,000)

90,000 – 54,000

36,000 gallons

Well field Capacity with Largest Well Out-of-Service

(Equation #2)

Storage Requirement

=

5/4 x ADD – 1/4 x capacity

(5/4) (72,000) – (1/4)(180,000)

90,000 – 45,000

45,000 gallons

Conclusion: Storage Requirement = 45,000 gallons

*values obtained from water usage table in B

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 22 of 77

3.5 New Well Construction

3.5.1 Requirements

Well construction shall be such as to prevent contamination of the water and of the water-bearing

formation by either surface or subsurface sources (OAC Rule 3745-9-05).

3.5.2 Procedure

Wells shall be drilled, constructed, grouted and developed in accordance with Ohio EPA’s Water Well

Standards (OAC Rule 3745-9).

3.5.3 Standards

The most recent edition of Ohio EPA’s Water Well Standards (OAC Chapter 3745-9) applies to all well

construction and should be consulted for specific information. General criteria, applicable to all

wells, are as follows:

1. Minimum casing diameter is 5 inches.

2. Well casing height above finished grade shall be at least 12 inches and at least 12 inches above

the well house floor or concrete apron surface.

3. Solid, watertight casing shall extend at least 25 feet below ground surface.

4. Minimum grout depth shall be 25 feet below ground surface (OAC Rules 3745-9-06 & 07).

5. A well cap shall be provided. Electrical conduit connections on the well cap shall be threaded or

sealed to prevent the entrance of insects and water. Well cap shall conform to ‘Water System

Council Pitless Adaptor Standard PAS-97’ or with an alternative standard acceptable to the

director. In circumstances where an alternative well cap is required based upon the well

construction or geologic setting, the alternative well cap must be approved by the director prior

to installation.

6. The well shall be provided with a downturned screened vent. Well vents that are integral with

the well cap are acceptable so long as they are screened and face downward. When vertical

turbine pumps are used, access for water level measurements must be provided.

7. Pitless adaptors or pitless units shall be lead free and conform to “Water Systems Council Pitless

Adaptor Standard PAS-97” or with an alternative standard acceptable to the director.

8. Well screen shall be installed where the geological formations are unconsolidated or

incompetent.

9. A check valve or foot valve should be provided within the drop pipe.

10. A submersible well pump shall neither have a mercury seal, nor shall any other components of

the well construction contain mercury.

11. Each well shall be provided with a smooth nose (no threads on spigot) sample tap for collecting

raw water samples. The sample tap can be located in a valve pit or other location which is

accessible and protected from freezing. Commercial sampling hydrants may be considered.

The sample tap shall be located prior to any pressure tanks or treatment units and shall allow

for collection of a representative ground water sample from each well.

12. Each well is to be provided with a means to isolate it, sample it and pump it to waste while

keeping all remaining wells in service. Yard hydrants at the wellhead may be suitable for

sampling and pumping to waste. Sanitary yard hydrants, if used, must conform to OAC Rule

3745-95-09.

13. Well casing shall conform to the following:

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 23 of 77

Steel [See OAC Rule 3745-9-05]

Minimum thickness

Pipe specification

Joint specifications

PVC [See OAC 3745-9-05]

Minimum SDR

Pipe specification

Joint specifications

The use of PVC casing is generally not approved for wells near underground fuel storage,

known soil contamination or other sources of chemicals that can degrade and permeate PVC.

14. The water service pipe installed below ground, between the well and the treatment plant, shall

be maintained under system pressure at all times. A check valve or backflow prevention

assembly shall not be installed between the pitless device and the pressure tank.

15. The water service pipe installed below ground, between the well and the treatment plant or

distribution system, shall be sufficiently buried to prevent it from freezing (typically 4 feet).

16. The water service pipe installed below ground, between the well and the treatment plant or

distribution system, shall be certified for potable water use by either the National Sanitation

Foundation (NSF) or American Water Works Association (AWWA).

17. The “Well Profile and Construction Form” (Figure 4) is an illustration of well terminal

development and includes most specifications needed for plan approval. This form should only

be used for single cased wells with submersible pumps and pitless adaptors. Other well

configurations (gravel packing, vertical turbine pumps, etc.) shall have a plan submitted

showing the actual construction of the well.

3.6 Casing Extensions

If an extension to an existing well casing is needed to meet the required height above finished grade, a

below grade bolted steel coupling may be used. Such couplings may be used to join similar or dissimilar

materials or sizes. Bolted steel couplings used for this purpose must conform to the following criteria:

1. Conform to ANSI/AWWA Standard C219 Bolted, Sleeve-Type Couplings for Plain-End Pipe", catalog

number 43219.

2. Have a collar with the same or better strength and rigidity of the well casings being joined together.

3. Be composed of a cast steel unit joined by a minimum of four stainless steel bolts spaced uniformly

around the circumference of the coupling.

4. Provide for the well casing to extend at least 2.5 inches into the throat of the coupling. Ensure that the

coupling is centered over the joint.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 24 of 77

5. A connection to a well casing that is made above ground shall be installed through the following

methods:

a. Threaded connection.

b. Welded connection.

c. Bolted flanges with rubber gaskets at twelve inches or greater above ground surface.

d. Extension of the casing at least 0.5 inch into the base of a pump mounted on and sealed to a

concrete pedestal.

Figure 4 - Well Profile and Construction Form

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 25 of 77

3.7 Approval of Existing Wells as Public Water Supply Wells

3.7.1 Requirements

Existing private wells, unapproved wells or non-potable wells, to be converted into public water

supply wells shall meet the same requirements and standards as a new well. In addition, assurance is

required that the well has been properly constructed and that the well is in satisfactory condition.

3.7.2 Detail Plan Approval Exemptions

Water systems newly discovered or re-opened after temporarily closing and meeting the definition of

a public water system in OAC Rule 3745-81-01, are exempted from obtaining plan approval for wells if

all of the following conditions are met:

1. A complete well analysis (including total coliforms count and possibly nitrate) is submitted and

demonstrates acceptable water quality, or a variance is granted in accordance with OAC Rule

3745-9-02, except in the following two circumstances:

1.1. Community or nontransient noncommunity public water systems that have been closed for

less than three years;

1.2. Transient noncommunity public water systems that have been closed for less than five

years.

2. A well meeting minimum casing depth or casing height standards, contained in OAC Chapter

3745-9 as documented by the Director,.

3. All well siting requirements are met in accordance with OAC Rule 3745-9-04..

3.7.3 Procedure

Follow the same procedure as for new well approval. In addition, a water system contractor holding a

valid registration from the Ohio Department of Health shall inspect the well for acceptability

regarding:

1. Casing condition.

2. Total cased depth.

3. Total well depth.

4. Length and depth of the well screen(s).

5. Upper terminal development including the pitless installation device, grouting, venting, water

tight well cap and freeze protection for the discharge line. In addition, a well log and/or a well

construction work sheet (see Appendix C and Appendix D) must be completed and submitted.

3.7.4 Standards

1. Corrosion: The casing shall be free of excessive corrosion.

2. Casing Depth: The cased depth shall be at least 25 feet unless otherwise approved.

3. Pitless Installation Device: The pitless installation device shall conform to National Sanitation

Foundation or Water System Council Standards and be free of defects which could lead to

leakage.

4. Freeze Protection: The pitless installation device and discharge line shall be installed at sufficient

depth (normally about 4 feet) below ground surface to avoid freezing.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 26 of 77

3.8 Pumping Tests

A pumping test is required to determine the amount of water that can be safely withdrawn from the well for an

indefinite period of time. The pumping test shall be used to determine the specific capacity of the well at the

anticipated permanent design pumping rate for all high use wells intended to serve as a source to a community

public water system. There are three variations of the pumping test based upon whether the well is classified as

low, medium or high use as explained in the table below.

Classification

Estimated Average Daily Demand of the Well (gallons per day)

Low use

0 - 10,000

Medium use

10,001 - 100,000

High use

greater than 100,000

3.8.1 Pumping Test Rates

Acceptable pumping tests for low, medium or high use classification are as follows:

1. For low or medium use wells, the pumping test shall be conducted at a constant rate for a period

of at least normal operation either at the peak hourly demand, or at least 1.5 times the anticipated

permanent design pumping rate whichever is greater. If the well cannot sustain peak hourly

demand, the pumping test shall be conducted at a minimum of 1.5 times the anticipated design

pumping rate.For a community water system well, the duration of the constant rate pumping test

shall be no less than twenty-four hours.

2. For all high use wells, a step-drawdown test shall be conducted, followed by a constant rate

pumping test.

a. The step-drawdown test shall be used to obtain sufficient hydrogeologic information to

design an appropriate constant rate pumping test for the well. The step draw-down test

shall, at a minimum conform to the following:

i. Consist of three or more steps of progressively increasing pumping rates.

ii. One step shall be performed at the anticipated permanent design pumping rate.

iii. Each step shall be of approximately equal duration.

iv. Each step shall be performed at a constant pumping rate for no less than forty-

five minutes.

b. The constant rate pumping test shall be conducted for at least twenty-four hours at a

pumping rate of at least 1.5 times the anticipated permanent design pumping rate. The

constant rate pumping test shall not commence until the water level has recovered to at

least ninety percent of the drawdown caused by the step-drawdown test or twenty-four

hours after the completion of the step-drawdown test, whichever comes first. For high

use wells, all pumping tests shall include water level measurements from observation or

surrounding wells.

3.8.2 Reduced Rate Pumping Test

For low, medium or high use wells, the constant rate pumping test may be conducted at a lower

pumping rate if it is believed pumping the well at 1.5 times the anticipated permanent pump design

rate will be excessive, will not be possible, or will have adverse effects on the long-term performance

of the well or aquifer. The test may be conducted at a lower pumping rate if the following criteria are

met:

1. The constant rate pumping test is conducted at no less than 1.2 times the pump design rate.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 27 of 77

2. A demonstration is provided that supports the reasoning for a lower pumping rate that even

under adverse conditions, including but not limited to severe drought, the well will likely be able

to supply water at the anticipated permanent design pumping rate over the anticipated functional

life of the well.

Regardless of well classification, the capacity of the design pump may not exceed the pumping test

rate. The capacity of the permanent pump must be equal to or less than the constant pumping test

rate.

NOTE: It is recommended that a person with demonstrated competency perform the respective

pumping test or aquifer test.

3.8.3 Sampling

Samples shall be collected and analyzed from a public water system well for contaminants at the

conclusion of the constant rate pumping test, and prior to initiation of the recovery period. The list of

contaminants may contain inorganics, radiologicals, synthetic organic chemicals (SOCs), volatile

organic compounds (VOCs), Per- and polyfluoroalkyl Substances (PFAS), and bacteria. The

contaminants required for each type of public water system are listed in the Appendices of OAC Rule

3745-9-09.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 28 of 77

3.9 Reporting

The following records are to be included with detailed plan submission:

3.9.1 Well Logs

A well log is to be recorded with the Ohio Department of Natural Resources (ODNR) by the driller at

the time the well is drilled. A copy of a properly filed ODNR well log must be submitted to Ohio EPA

as part of the detail plans for a new well.

Copies of existing well logs may be obtained from the Water Wells Database provided by ODNR.

Contact ODNR, Division of Geological Survey, by e-mail at geo.survey@dnr.ohio.gov or by phone at

(614) 265-6576 with questions concerning the water well database.

3.9.2 Pumping Test Report

A report shall be submitted which includes the pumping tests with their results, interpretations, and

conclusions. For all wells, the pumping test report shall include items in 1-8 at minimum:

1. Date and times of starting through ending pumping test.

2. Pumping rate and depth at which the pump used for the test was set.

3. A data table for each well used to observe the drawdown and recovery water level

measurements, showing the time after the pump test started and the corresponding water level

measurements to the nearest 0.1 foot.

Water level measurements shall be at these time intervals:

Time after Pumping Test Started

(minute)

Time Interval Between

Measurements (minute)

0-15

16-60

61-120

121-180

181-300

Greater than 300

1

5

10

20

30

60

4. Specific capacity of the well at the tested pumping rates.

5. For high use wells only, the specific capacity of the well at the anticipated permanent design

pumping rate after drawdown has stabilized.

6. Anticipated permanent pump setting depth (in feet below ground).

7. Height above ground (in feet) of the water level measurement reference point.

8. Water level measurements must be taken immediately after termination of the constant rate

pumping test at time intervals of five minutes for the first hour and every thirty minutes

thereafter until the water level has recovered to at least ninety percent of the drawdown caused

by the pumping test.

1. In addition to the requirements 1 through 8 listed above, a high use water system well

pumping test report shall also include:

a) A map showing the location of the pumping wells and the location of other

wells used to observe drawdown. The map shall, at a minimum, include the

names of the wells as used in the report and the distance between the pumping

well and other wells used to observe drawdown.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 29 of 77

b) Graphs plotted on semi-logarithmic graph paper showing the drawdown

measurements on the arithmetic scale and time on the logarithmic scale.

Graphs must be submitted for the pumping well and any other wells used to

observe drawdown and recovery during the pumping test.

c) Graphs plotted on semi-logarithmic graph paper showing the recovery

measurements on the arithmetic scale and time on the logarithmic scale.

Graphs must be submitted for the pumping well and any other wells used to

observe drawdown and recovery during the pumping test.

d) Arithmetic graphs showing all water-level data collected during the pumping

test and recovery period from the pumping well and all observation wells.

9. If the high use well is part of a multiple-well system the report shall also include documentation

demonstrating:

1. The well can supply water at the anticipated permanent design pumping rate while at

minimum maintaining the operational capacity of the well field and without degrading

the water quality of any well in the well field.

2. Analyses of the effects of interference drawdown from other wells owned by the PWS, as

well as other high capacity wells not owned by the PWS. Operational practices and the

potential to cause degradation of water quality at the well field should also be considered

when establishing a permanent design pumping rate for a new PWS well.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 30 of 77

3.10 Disinfection of Wells

3.10.1 Requirements

All wells shall be properly disinfected by chlorination before being placed into service. OAC Rule

3745-9-08 specifies well disinfection procedures and should be consulted; however, a summary is

provided below.

3.10.2 Procedure

1. Disinfectant shall be slowly poured into the well by wetting the inside casing circumference,

drop pipe and electrical cable.

2. Disinfectant concentration in the water column shall be initially at least one hundred

milligrams per liter chlorine. AWWA specification, C654-13, can be consulted to determine the

necessary amount of sodium or calcium hypochlorite needed. If using unscented bleach, the

following formula can be used:

(R)2(D)(0.000272) = gallons of bleach containing 6% sodium hypochlorite

R = radius of the well in inches

D = depth of water in the well in feet

3. Water in the well shall be agitated or surged to ensure even dispersal of the disinfectant

throughout the entire water column. Recirculating water back into the well casing from an

outside spigot may distribute chlorine throughout the water column if the well pump is located

at the bottom of the well.

4. Cap the well and allow it to stand at least eight hours.

5. After disinfection, a well shall not supply water for human consumption until it has been found

to be microbiologically safe. Total coliform samples shall be collected at least eight hours after

disinfection and after all residual chlorine is completely flushed from the well. Total chlorine

shall be tested and the results of the test noted on the sample submission form. Total chlorine

shall be undetectable before total coliform sampling for microbiological samples. Two

consecutive total coliform samples, at least thirty minutes apart, must be total coliform negative

before the well can supply water for human consumption. It is preferred the samples be

collected twenty-four hours apart. An Ohio EPA certified laboratory must be used for bacterial

analysis.

6. If any of the bacterial samples taken from the well in step 5 are reported as total coliform-

positive (unsafe), repeat step 1 through step 5.

7. If the water is reported as total coliform positive (unsafe) after repeating the procedure two

times, contact the District Office.

EXAMPLE

6 inch diameter well

40 feet of water in the well

(3)

2

(40)(0.000272) = 0.097 gallons (approximately 0.1 gallons, or 1.5 cups)

Therefore: 0.1 gallons (1.5 cups) of bleach containing 6% sodium hypochlorite will

establish a chlorine residual of 100 mg/L in a 6-inch well that has 40 feet of water.

Guidelines for Design of Small Public Ground Water Systems

June 2023

Page 31 of 77

NOTE: When calcium hypochlorite is used for disinfection, the tablets or granules shall be completely

dissolved in water prior to placement into the well.

Sodium hypochlorite solution with fragrance additives shall not be used for disinfection.

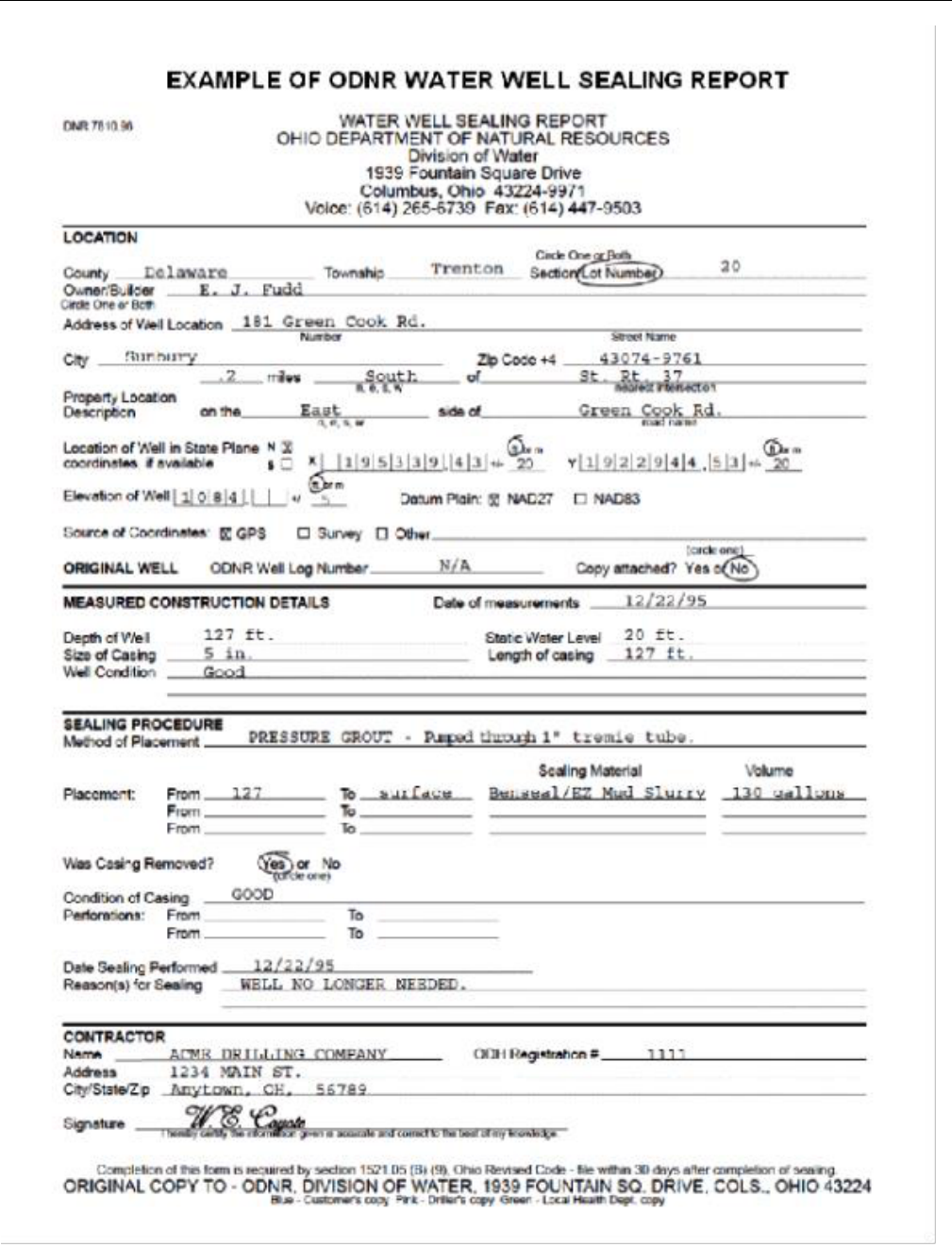

3.11 Sealing of Wells That Are No Longer Used or Needed

3.11.1 Requirements

A well or dry hole whose use has been permanently discontinued, shall be properly sealed. A test

hole that is not converted into a well upon completion of testing shall also be properly sealed.

Sealing shall be in accordance with OAC Rules 3745-9-10 and 3745¬-9-07 and “The State of Ohio

Regulations and Technical Guidance for Sealing Unused Water Wells and Boreholes.”

3.11.2 Procedure

Engage a qualified ground water professional, engineer or Ohio Department of Health registered

well driller familiar with proper sealing procedures to perform or supervise abandonment of the

well. The sealing procedure from OAC Rule 3745-9-10 for a non-artesian well that is constructed

through a single aquifer is summarized below:

1. All obstructions shall be removed, including the pump and related equipment, drop pipe,

pitless adapter, suction line, trash or other debris.

2. The casing shall be removed, ripped or perforated. Casing shall be removed if the annular

seal is inadequate or water is flowing from around the outside of the casing. If none of these

conditions are present the casing may be left intact or in-place with prior approval of the

District Office.

3. If microbiological growth is present, the well shall be disinfected with sodium hypochlorite

or calcium hypochlorite to achieve at least 50 mg/L total chlorine in the water column.

4. The well can be either entirely filled with bentonite or it can be filled with clean and

disinfected sand or gravel in the bottom followed by a bentonite cap. If sand or gravel is to

be used then it may be placed no higher than the top of the aquifer or 25 feet below the

ground surface, whichever is lower.

Coarse grade bentonite can be used to seal wells that are larger than 4 inches in diameter

and less than 200 feet deep. Pelletized bentonite can be used to seal wells that are larger than

4 inches in diameter and less than 100 feet deep. Wells that are either more than 200 feet

deep or less than 4 inches in diameter will require special bentonite placement and the

District Office should be consulted.

If the casing is to be removed, the sealing material and grout shall be placed concurrently

with casing removal.

5. After the sealing material and grout have been placed into the well, the grout shall cure a

minimum of twelve hours to assess whether any settling of the sealing material has

occurred. If settling has occurred, additional grout shall be placed into the well.

6. Casing shall be removed to a depth of at least 3 feet below ground surface. The remaining

hole should be filled with clean clay.

7. Obtain, complete and submit a uniquely numbered well sealing report to the Ohio

Department of Natural Resources, Division of Soil and Water Resources. Also, submit a copy

to the Ohio EPA District Office. A sample well sealing report is included in Appendix F.

Guidelines for Design of Small Public Ground Water Systems

June 2023