NiceLabel 2019 Designer User

Guide

Rev-2020-11 ©NiceLabel 2020.

PowerForms Edition

Table of Contents

1. Introduction ..................................................................................................................... 12

1.1. Basic Designer Concepts ...................................................................................... 12

1.1.1. Label .......................................................................................................... 12

1.1.2. Form .......................................................................................................... 13

1.1.3. Solution ..................................................................................................... 13

1.1.4. Object ........................................................................................................ 14

1.1.5. Document .................................................................................................. 14

1.1.6. Design Surface ........................................................................................... 15

1.1.7. Data Sources ............................................................................................. 15

1.1.8. Dynamic Data Manager ............................................................................... 16

1.1.9. Dynamic Data Explorer ............................................................................... 17

1.1.10. Layers ...................................................................................................... 17

1.1.11. Solution Explorer ...................................................................................... 18

1.1.12. Actions Editor ........................................................................................... 18

1.1.12.1. Ribbon .......................................................................................... 19

1.1.12.2. Actions Explorer ............................................................................ 20

1.1.12.3. Editing eld ................................................................................... 21

1.2. Keyboard and Mouse Support ............................................................................... 22

1.2.1. Ecient Use of Keyboard and Mouse .......................................................... 22

1.2.2. Mouse Wheel Support ................................................................................ 23

1.2.3. Keyboard Shortcuts ................................................................................... 23

1.3. Options (Conguring the Program) ......................................................................... 24

2. Workspace Overview ....................................................................................................... 26

2.1. Landing Page ........................................................................................................ 27

2.2. Object and Explorer Panels .................................................................................... 28

2.3. Layers Panel ......................................................................................................... 29

2.3.1. Working with the Layers panel ..................................................................... 30

2.3.2. Positioning your objects using layers ........................................................... 31

2.3.3. For easier designing: layer states ................................................................ 31

2.3.4. Keeping layers organized using the right-click menu .................................... 33

2.4. Objects Panel ........................................................................................................ 34

2.5. Printer and Status Bar ............................................................................................ 35

2.5.1. Status Bar Printer Selection ........................................................................ 36

2.5.2. Windows Printing Mode .............................................................................. 36

2.6. Tabs and Ribbons .................................................................................................. 37

2.6.1. Tabs ........................................................................................................... 37

2.6.2. Ribbon ....................................................................................................... 37

2.6.3. File Tab ...................................................................................................... 38

2.6.3.1. Start ................................................................................................ 39

2.6.3.2. New ................................................................................................ 39

2.6.3.3. Open ............................................................................................... 40

2.6.3.4. File Tab Import ................................................................................. 40

2.6.3.5. Save ................................................................................................ 40

2

2.6.3.6. Save as ........................................................................................... 41

2.6.3.7. Print ................................................................................................ 41

2.6.3.8. Store/Recall Printing Mode ............................................................... 41

2.6.3.9. Protection ....................................................................................... 42

2.6.3.10. Options (Conguring the Program) ................................................. 43

2.6.3.11. About ............................................................................................ 50

2.6.4. Home Tab ................................................................................................... 52

2.6.4.1. Clipboard ........................................................................................ 53

2.6.4.2. Font ................................................................................................ 54

2.6.4.3. Action ............................................................................................. 54

2.6.4.4. Management ................................................................................... 56

2.6.4.5. Align ................................................................................................ 56

2.6.4.6. Objects ........................................................................................... 56

2.6.5. Data Tab ..................................................................................................... 57

2.6.5.1. Step-by-Step Database Wizard ........................................................ 57

2.6.5.2. Data Source Management ................................................................ 58

2.6.6. View Tab .................................................................................................... 59

2.6.6.1. Zoom .............................................................................................. 59

2.6.6.2. Object Markers Visibility .................................................................. 60

2.6.6.3. Alignment and Gridline Guides ......................................................... 60

2.6.6.4. Rotation .......................................................................................... 60

2.6.7. Solution Tab ............................................................................................... 61

2.6.7.1. Clipboard ........................................................................................ 61

2.6.7.2. New ................................................................................................ 62

2.6.7.3. Action ............................................................................................. 62

2.6.7.4. Import and Export ............................................................................ 62

2.6.8. Contextual Tabs ......................................................................................... 63

2.6.8.1. Label-specic Contextual Tabs ........................................................ 63

2.6.8.2. Form-specic Contextual Tabs ......................................................... 77

2.6.8.3. Document Storage .......................................................................... 83

2.6.9. Help Tab ..................................................................................................... 84

2.6.10. RFID Tag ................................................................................................... 85

2.6.10.1. Tag ................................................................................................ 85

2.6.10.2. Content ......................................................................................... 86

2.6.10.3. Security ........................................................................................ 87

2.6.10.4. Settings ........................................................................................ 90

2.6.10.5. RFID Read and Print ....................................................................... 91

2.7. Design Surface ..................................................................................................... 93

2.7.1. Design Surface Elements ............................................................................ 93

2.7.2. Design Surface Editing Actions ................................................................... 94

2.7.3. Visual Aid Elements .................................................................................... 95

2.7.4. Object Properties Window .......................................................................... 95

2.8. Document Properties and Management Dialogs ..................................................... 96

2.8.1. Label Properties ......................................................................................... 96

2.8.2. Form Properties ......................................................................................... 97

2.8.3. Dynamic Data Manager ............................................................................... 98

3

2.8.3.1. Dynamic Data Manager Ribbon ........................................................ 99

2.8.3.2. Dynamic Data Explorer ................................................................... 102

2.9. Object Properties Editor ...................................................................................... 103

2.10. Context Menus .................................................................................................. 103

2.10.1. Design Surface Context Menu ................................................................. 103

2.10.2. Object Context Menu .............................................................................. 104

2.10.3. Group Context Menu .............................................................................. 105

3. Label ............................................................................................................................. 108

3.1. New Label Setup Wizard ...................................................................................... 108

3.1.1. Step 1: Select the Printer .......................................................................... 109

3.1.2. Step 2: Set the Page Size .......................................................................... 111

3.1.3. Step 3: Select the Label Layout ................................................................. 112

3.1.4. Step 4: Specify the Label Dimensions ....................................................... 112

3.1.5. Step 5: Summary ...................................................................................... 112

3.2. Label Properties .................................................................................................. 113

3.2.1. Printer ...................................................................................................... 114

3.2.2. Label Dimensions ..................................................................................... 118

3.2.3. Paper ....................................................................................................... 119

3.2.4. Stocks ..................................................................................................... 120

3.2.5. Style ........................................................................................................ 121

3.2.6. Batch Printing ........................................................................................... 122

3.2.7. Cutter ...................................................................................................... 124

3.2.8. Info .......................................................................................................... 125

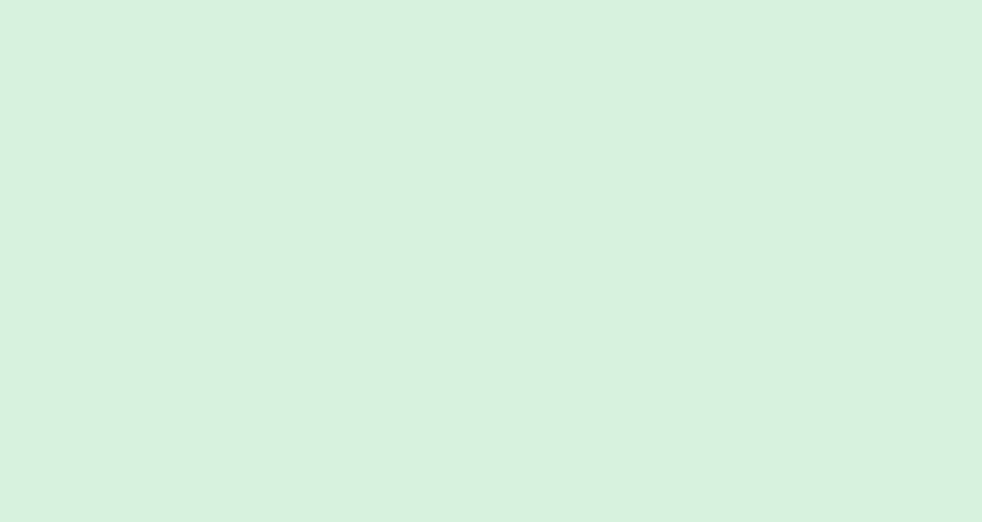

3.3. Label Objects ...................................................................................................... 125

3.3.1. Text .......................................................................................................... 126

3.3.1.1. Source .......................................................................................... 126

3.3.1.2. Style ............................................................................................. 127

3.3.1.3. Eects .......................................................................................... 128

3.3.1.4. Position ......................................................................................... 128

3.3.1.5. Relative position ............................................................................ 129

3.3.1.6. General ......................................................................................... 130

3.3.2. Text Box ................................................................................................... 131

3.3.2.1. Source .......................................................................................... 131

3.3.2.2. Style ............................................................................................. 132

3.3.2.3. Text Fit .......................................................................................... 133

3.3.2.4. Eects .......................................................................................... 134

3.3.2.5. Boundaries .................................................................................... 134

3.3.2.6. Position ......................................................................................... 135

3.3.2.7. General ......................................................................................... 136

3.3.3. Rich Text Box ............................................................................................ 137

3.3.3.1. Source .......................................................................................... 137

3.3.3.2. Style ............................................................................................. 138

3.3.3.3. Text Fit .......................................................................................... 139

3.3.3.4. Position ......................................................................................... 139

3.3.3.5. Relative Position ............................................................................ 140

3.3.3.6. General ......................................................................................... 141

4

3.3.3.7. Rich Text Box Editor ....................................................................... 141

3.3.4. Barcode ................................................................................................... 143

3.3.5. Picture ..................................................................................................... 143

3.3.5.1. Source .......................................................................................... 144

3.3.5.2. Base64 encoded graphics .............................................................. 144

3.3.5.3. BLOB elds support ....................................................................... 145

3.3.5.4. Style ............................................................................................. 145

3.3.5.5. Position ......................................................................................... 146

3.3.5.6. General ......................................................................................... 148

3.3.6. Rectangle ................................................................................................. 149

3.3.6.1. Position ......................................................................................... 150

3.3.6.2. General ......................................................................................... 152

3.3.7. Line ......................................................................................................... 153

3.3.7.1. Position ......................................................................................... 154

3.3.7.2. General ......................................................................................... 154

3.3.8. Ellipse ...................................................................................................... 156

3.3.8.1. Position ......................................................................................... 157

3.3.8.2. General ......................................................................................... 159

3.3.9. Inverse ..................................................................................................... 160

3.3.9.1. About ............................................................................................ 160

3.3.9.2. Position ......................................................................................... 160

3.3.9.3. General ......................................................................................... 162

3.3.10. Reports .................................................................................................. 163

3.3.10.1. Report elements .......................................................................... 164

3.3.10.2. Creating new reports ................................................................... 166

3.3.10.3. Adding objects to reports ............................................................ 168

3.3.10.4. Conguring Repeater Denitions .................................................. 169

3.3.10.5. Adding headers and footers ......................................................... 170

3.3.10.6. Adding dynamic objects to headers and footers ........................... 171

3.3.10.7. Adding page numbers .................................................................. 172

3.4. Working with Objects .......................................................................................... 172

3.4.1. Adding Objects ........................................................................................ 173

3.4.2. Adding Objects with Connected Data Source ............................................ 173

3.4.3. Grouping .................................................................................................. 174

3.4.4. Rotating ................................................................................................... 175

3.4.5. Object Resizing ........................................................................................ 175

3.4.5.1. Graphic Object resizing .................................................................. 176

3.4.5.2. Automatic Resizing with Form ......................................................... 176

3.4.5.3. Table Column Resizing ................................................................... 176

3.5. Label Saving ....................................................................................................... 177

3.5.1. Label Files vs. Solution Files ...................................................................... 177

3.5.2. Label Storage ........................................................................................... 177

4. Barcode ......................................................................................................................... 178

4.1. Source ................................................................................................................ 178

4.2. Barcode .............................................................................................................. 178

4.3. Check Digit ......................................................................................................... 179

5

4.4. Human Readable ................................................................................................. 180

4.5. Bearer Bar ........................................................................................................... 181

4.6. Details ................................................................................................................ 181

4.7. Position .............................................................................................................. 181

4.8. Relative Position .................................................................................................. 182

4.9. General ............................................................................................................... 183

4.10. Available Barcodes and Their Settings ............................................................... 185

4.10.1. 2D Barcodes .......................................................................................... 193

4.10.2. GS1 DataBar Subtypes ........................................................................... 195

4.10.2.1. Linear Symbol Types .................................................................... 195

4.10.2.2. Composite Symbol Types ............................................................ 196

4.11. 1D Barcode Details ............................................................................................ 197

4.12. 2D Barcode Details ............................................................................................ 198

4.12.1. Code Page ............................................................................................. 198

4.12.2. Columns ................................................................................................ 199

4.12.3. Compaction Mode .................................................................................. 199

4.12.4. Encoding ................................................................................................ 199

4.12.5. ECI Encoding .......................................................................................... 199

4.12.6. Error Correction Level ............................................................................. 200

4.12.7. Format ................................................................................................... 200

4.12.8. Rows ...................................................................................................... 201

4.12.9. Symbol Version ...................................................................................... 201

4.12.10. Truncated ............................................................................................. 201

4.12.11. Version ................................................................................................ 201

4.13. GS1 DataBar Specics ...................................................................................... 201

4.13.1. GS1 DataBar Source ............................................................................... 201

4.13.2. GS1 DataBar Properties .......................................................................... 202

4.14. Maxicode Barcode Content ............................................................................... 202

4.15. USPS Intelligent Mail Barcode Content ............................................................... 204

5. Printing .......................................................................................................................... 205

5.1. Print Pane (Default Printing Form) ......................................................................... 205

5.2. Edit Printing Form ................................................................................................ 209

5.3. Printing Procedure .............................................................................................. 209

5.4. Store/Recall Printing Mode .................................................................................. 211

5.5. Optimize Printing Speed ...................................................................................... 212

5.6. Printing from Databases ...................................................................................... 213

5.7. Changing Common Printer Settings ..................................................................... 214

5.8. Changing Dithering Options ................................................................................ 215

5.9. Double-sided Printing .......................................................................................... 216

5.10. Dening Unprintable Area .................................................................................. 217

6. Dynamic Data Sources ................................................................................................... 219

6.1. Variables ............................................................................................................. 219

6.1.1. Variable .................................................................................................... 220

6.1.1.1. General ......................................................................................... 220

6.1.1.2. Text ............................................................................................... 224

6.1.1.3. Date .............................................................................................. 225

6

6.1.1.4. Time .............................................................................................. 227

6.1.1.5. Floating Point ................................................................................ 228

6.1.1.6. Currency ....................................................................................... 230

6.1.2. Current Date ............................................................................................ 233

6.1.2.1. General Tab ................................................................................... 233

6.1.2.2. Output Rules ................................................................................. 234

6.1.2.3. Date Formats ................................................................................. 234

6.1.3. Current Time ............................................................................................ 235

6.1.3.1. General Tab ................................................................................... 235

6.1.3.2. Output Rules ................................................................................. 236

6.1.3.3. Time Formats ................................................................................ 236

6.1.4. Counter ................................................................................................... 237

6.1.4.1. General Tab ................................................................................... 237

6.1.5. Prompting ................................................................................................ 241

6.1.6. Printing Form Variables ............................................................................. 241

6.2. Functions ............................................................................................................ 243

6.2.1. Subset ..................................................................................................... 245

6.2.2. Concatenate ............................................................................................ 246

6.2.3. Date Oset .............................................................................................. 247

6.2.4. Linear ...................................................................................................... 248

6.2.5. VBScript .................................................................................................. 249

6.2.6. VBScript Expression ................................................................................. 250

6.2.6.1. Script Editor .................................................................................. 250

6.2.7. Python Script ........................................................................................... 252

6.2.8. HIBC ........................................................................................................ 253

6.2.9. GS1-128 .................................................................................................. 254

6.2.10. ANSI MH10.8.2 (ASC) .............................................................................. 255

6.2.11. Transfer Data Syntax for High Capacity ADC Media .................................. 256

6.2.12. Read from File ........................................................................................ 258

6.2.13. NDEF Message ....................................................................................... 258

6.3. Databases .......................................................................................................... 260

6.3.1. Supported Database Types ....................................................................... 260

6.3.2. Database Connection Options .................................................................. 261

6.3.3. Step-by-Step Database Wizard ................................................................. 262

6.3.3.1. Adding a Database ......................................................................... 262

6.3.3.2. Database Wizard for Excel Files ...................................................... 263

6.3.3.3. Database Wizard for Access Database ........................................... 266

6.3.3.4. Database Wizard for Microsoft SQL Server Database ...................... 269

6.3.3.5. Database Wizard for Text Files ........................................................ 272

6.3.3.6. Database Wizard for Oracle Database ............................................. 274

6.3.3.7. Database Wizard for MySQL Database ............................................ 277

6.3.3.8. Database Wizard for Adding Databases via OLE DB ......................... 280

6.3.3.9. Database Wizard for ODBC Data Sources ....................................... 284

6.3.3.10. Database Editing .......................................................................... 287

6.3.4. Manual Database Connection Setup ......................................................... 290

6.3.4.1. Connect to Microsoft Excel File ...................................................... 290

7

6.3.4.2. Connect to Microsoft Access File ................................................... 293

6.3.4.3. Connect to Microsoft SQL Server Database .................................... 295

6.3.4.4. Connect to Text File ....................................................................... 298

6.3.4.5. Connect to Oracle Database .......................................................... 300

6.3.4.6. Connect to MySQL Database ......................................................... 304

6.3.4.7. Connect to Other Databases (OLE DB) ............................................ 306

6.3.4.8. Connect to ODBC Data Source ....................................................... 310

6.3.4.9. Database Table Conguration ........................................................ 312

6.3.4.10. Database Field Conguration ....................................................... 316

6.3.4.11. Databases with Custom SQL Queries ........................................... 318

6.3.4.12. Database Connection Conguration ............................................. 319

6.3.4.13. Using Text File Structure Wizard ................................................... 320

6.3.4.14. Database Connection Conguration for Text Files ......................... 322

6.4. Internal Variables ................................................................................................. 324

6.5. Global Variables .................................................................................................. 325

6.5.1. Adding Global Variables as Object Data Sources ........................................ 326

6.5.2. Global Variable Conguration .................................................................... 327

6.5.2.1. General Tab ................................................................................... 327

6.6. Adding and Deleting Data Sources ....................................................................... 329

6.7. Groups of Permitted Input Characters .................................................................. 330

6.8. Special Character Shortcuts ................................................................................ 330

7. Solutions ....................................................................................................................... 333

7.1. Create or Edit a Solution ...................................................................................... 333

7.2. Accessing Files in Solution .................................................................................. 334

7.3. Create or Edit a Label in a Solution ....................................................................... 334

7.4. Form ................................................................................................................... 335

7.4.1. Create or Edit a Form ................................................................................ 335

7.4.2. Form Properties ....................................................................................... 336

7.4.2.1. Basic Settings ............................................................................... 337

7.4.2.2. Additional Settings ........................................................................ 339

7.4.2.3. Style ............................................................................................. 339

7.4.2.4. Tab Order ...................................................................................... 340

7.4.2.5. F1 Help .......................................................................................... 340

7.4.2.6. Events ........................................................................................... 340

7.4.2.7. Variable Events .............................................................................. 341

7.4.2.8. Serial Port Data .............................................................................. 341

7.4.2.9. Info ............................................................................................... 343

7.4.3. Adding Objects to a Form ......................................................................... 343

7.4.4. Form Objects ........................................................................................... 343

7.4.4.1. Frame ............................................................................................ 345

7.4.4.2. Text ............................................................................................... 347

7.4.4.3. Picture .......................................................................................... 350

7.4.4.4. Button ........................................................................................... 352

7.4.4.5. Button Group ................................................................................. 356

7.4.4.6. Edit Field ....................................................................................... 360

7.4.4.7. Memo Field .................................................................................... 364

8

7.4.4.8. Combo Box ................................................................................... 367

7.4.4.9. List Box ......................................................................................... 371

7.4.4.10. Radio Group ................................................................................ 375

7.4.4.11. Checkbox .................................................................................... 379

7.4.4.12. Database Table ............................................................................ 382

7.4.4.13. Database Navigator ..................................................................... 387

7.4.4.14. Database Search ......................................................................... 389

7.4.4.15. Label Preview .............................................................................. 391

7.4.4.16. Data Initialization ......................................................................... 394

7.4.4.17. Printer Settings ............................................................................ 400

7.4.4.18. Print Quantity .............................................................................. 402

7.4.5. Run Form ................................................................................................. 405

7.4.6. Form Debugger ........................................................................................ 406

7.5. How To ................................................................................................................ 407

7.5.1. Printing with Forms ................................................................................... 407

7.5.1.1. Simple Printing with Forms ............................................................. 408

7.5.1.2. Printing Labels whose Names are Read from Database .................... 409

7.5.2. Import and Export .................................................................................... 410

7.6. Dene Actions .................................................................................................... 411

7.6.1. Actions Editor ........................................................................................... 412

7.6.1.1. Ribbon .......................................................................................... 413

7.6.1.2. Actions Explorer ............................................................................ 414

7.6.1.3. Editing eld ................................................................................... 414

7.6.2. Available Actions ...................................................................................... 415

7.6.2.1. General ......................................................................................... 417

7.6.2.2. Printer ........................................................................................... 428

7.6.2.3. Form ............................................................................................. 445

7.6.2.4. Variables ....................................................................................... 460

7.6.2.5. Data and Connectivity .................................................................... 468

7.6.2.6. File Operations .............................................................................. 489

7.6.2.7. Flow Control .................................................................................. 496

7.6.2.8. Other ............................................................................................ 503

7.6.3. Combining Values in an Object .................................................................. 519

7.6.4. Access to Shared Network Resources ....................................................... 520

7.6.4.1. User privileges for service mode .................................................... 520

7.6.4.2. UNC notation for network shares .................................................... 520

7.6.4.3. Notation for accessing les in Control Center ................................. 521

7.6.4.4. Printer drivers availability ............................................................... 521

7.6.5. Search Order for Requested Files .............................................................. 521

7.6.6. Spooler Status ID ..................................................................................... 522

8. NiceLabel Print .............................................................................................................. 523

8.1. Managing Document Locations ........................................................................... 523

8.2. Opening the Documents ..................................................................................... 523

8.3. Printing Using NiceLabel Print .............................................................................. 524

9. Reference ...................................................................................................................... 525

9.1. Command File Types ........................................................................................... 525

9

9.1.1. JOB Command File ................................................................................... 525

9.1.1.1. JOB Command File Denition ......................................................... 525

9.1.1.2. JOB Command File Example .......................................................... 531

9.1.2. XML Command File ................................................................................... 531

9.1.2.1. XML Command File Denition ........................................................ 532

9.1.2.2. XML Command File Example .......................................................... 536

9.1.3. CSV Command File ................................................................................... 536

9.1.3.1. CSV Command File Denition ......................................................... 537

9.1.3.2. CSV Command File Example .......................................................... 537

9.2. Variables Export File Denition ............................................................................ 537

9.2.1. .NLVR File Denition .................................................................................. 538

9.2.2. XML Schema Denition (XSD) for Label Specication XML ......................... 540

9.2.3. .NLVR File Example ................................................................................... 544

9.3. Oracle WMS File Denition .................................................................................. 545

9.3.1. XML DTD .................................................................................................. 546

9.3.2. Sample Oracle XML .................................................................................. 546

9.4. Importing Variables from Legacy Labels ............................................................... 547

9.5. Licensing and Printer Usage ................................................................................ 548

9.6. Spell Checking Support ....................................................................................... 549

9.7. Session Printing .................................................................................................. 551

9.8. Tracing Mode ...................................................................................................... 552

9.9. Synchronizing Cutter Settings with Printer ........................................................... 553

10. How To ........................................................................................................................ 555

10.1. Insert Characters with <#hex_code> Syntax ....................................................... 555

10.2. Insert Characters with <Alt>+<ASCII_code> ....................................................... 555

10.3. Automatic Font Replacement ............................................................................. 556

10.3.1. Conguring Font Mapping ...................................................................... 556

10.3.2. Sample Mapping Conguration ............................................................... 557

10.4. Formatting Allergens for Food Ingredients ......................................................... 557

10.4.1. Prerequisites .......................................................................................... 558

10.4.2. Applying formatting to allergens ............................................................. 558

10.4.3. Syntax of Allergen formatting functions ................................................... 560

10.4.3.1. User provided list of allergens ...................................................... 560

10.4.3.2. Allergens from Microsoft Excel spreadsheet ................................. 560

10.4.3.3. Allergens from Microsoft Access database ................................... 561

10.4.3.4. Allergens from Microsoft SQL Database ....................................... 561

10.4.3.5. Allergens from SQL Server ........................................................... 562

10.4.3.6. Allergens from Tags ..................................................................... 563

10.4.4. Syntax of Allergen formatting functions with support for exclusions ......... 563

10.4.4.1. User provided list of allergens ...................................................... 563

10.4.4.2. Allergens from Microsoft Excel spreadsheet ................................. 564

10.4.4.3. Allergens from Microsoft Access Database ................................... 565

10.4.4.4. Allergens from Microsoft SQL Database ....................................... 566

10.4.4.5. Allergens from SQL Server ........................................................... 567

10.5. Designing Labels with Variable Length ............................................................... 567

10.6. Multicolor Printing ............................................................................................. 569

10

10.7. How to Create GS1 Compliant Labels ................................................................. 570

10.8. Printing of Unlimited Data .................................................................................. 571

10.8.1. Label with Connected Database or Counter ............................................. 571

10.8.2. Label without connected Database or Counter ........................................ 572

10.9. Using the Internal Printer Counter ...................................................................... 572

10.10. Installation of Printer Drivers ............................................................................ 573

10.11. Creating Hyperlinks and Sending Emails on Forms ........................................... 574

11. Online Support ............................................................................................................ 576

11

1. Introduction

1.1. Basic Designer Concepts

This section describes the Designer elements that enable you to eciently design label templates or

to create and manage a complex labeling solution that includes multiple labels, dynamic data sources,

and automatically run actions.

PRODUCT LEVEL INFO

Solution building is available in PowerForms.

Listed below are the essential Designer concepts. Being familiar with them provides a perfect starting

point for successful labeling projects.

• Label

• Form

• Solution

• Object

• Document

• Design Surface

• Data Sources

• Dynamic Data Manager

• Dynamic Data Explorer

• Solution Manager

• Action Editor

If you come across any other unfamiliar items while working with Designer, refer to the Help tab.

1.1.1. Label

Label works as a template to add label objects and print using any kind of printing media.

Each object adds a dierent kind of content such as text, line, ellipse, barcode or rectangle to a label.

The content is either xed (manually entered by the user) or dynamic (dened using values from

connected data sources).

12

After nishing with your label design, you can print the labels using any of your installed printers.

PRODUCT LEVEL INFO

Solution building is available in PowerForms.

Designing of a printable label belongs to basic Designer tasks. Designer allows creating and printing

of stand-alone labels and labels that are included in a printing solution.

Read about how to create, design or edit a label here.

1.1.2. Form

PRODUCT LEVEL INFO

This section is applicable to PowerForms.

NiceLabel Designer form serves as a panel for entering, manipulating and viewing the data. The

advantage of using a form are simplied data-entry and label printing process for the end-user.

In NiceLabel Designer, a form is created within a printing solution. This means that a form is usually

built in combination with a predesigned label.

TIP

Forms allow you to build an entire tailor-made data handling system which is

adaptable to current business needs.

Read about how to create, design or edit a form here.

1.1.3. Solution

PRODUCT LEVEL INFO

This section is applicable to PowerForms.

NiceLabel Designer solution acts as a container which includes multiple documents – labels, forms

and shared data sources. A single solution enables dealing with any number of labels, forms and

shared variable data sources.

How do labels and forms cooperate in a solution? A label alone can be designed and printed.

Multiplied manual printing of a single label le is time consuming and dicult if the content needs to

13

be constantly updated. Therefore, NiceLabel introduced the ability to create forms which are

combined with labels in a solution.

As a part of a solution, label document(s) specify the layout of printed labels. Forms make sure the

content of printed labels is easily dened, edited, and updated. Forms also oer the user the control

over a wide range of data- and print-related actions.

The advantages of keeping multiple labels and forms in a single le are:

• Simplied management print outputs.

• Simpler and time ecient label designing and printing.

• Simplied use of shared variable data sources.

Read about how to create or edit a solution here.

1.1.4. Object

PRODUCT LEVEL INFO:

Creation of forms and use of form objects are available in PowerForms.

Object is the basic building block for designing labels and forms. To design a label or form means to

select, add, and position the objects on the design surface.

Example

Each object performs a dierent role. Text object is in most cases used for single-line textual content

that does not need to adapt its font size to the label design. Barcode object adds a barcode whose

type and content can be adapted to the needs of current document. Radio Group object to allow a

user to select a single item from a set of mutually exclusive items.

Label object types and their purpose are listed here.

Form object types and their purpose are listed here.

1.1.5. Document

The term document is used for labels and forms – it can be used interchangeably.

14

NOTE

Be careful not to mistake document with solution. A solution is always a stand-alone

le while a document – be it label or form – may be used as a stand-alone le or as a

part of a solution.

1.1.6. Design Surface

PRODUCT LEVEL INFO:

Creation of forms and use of form objects are available in PowerForms.

Your design surface is a place to create, add, position, and interconnect label and form objects.

To help you design labels and forms as simply and eciently as possible, your design surface uses

usability and functional principles from Microsoft Oce.

TIP

Use View tab to customize your design surface.

• Learn more about design surface elements here.

• Learn more about design surface editing actions here.

• Learn more about design surface visual aid elements here.

1.1.7. Data Sources

PRODUCT LEVEL INFO:

Creation of forms and use of form objects are available in PowerForms.

Data sources are containers that provide content for label or form objects. Available data sources of

NiceLabel Designer are listed and described in the table below:

Fixed data

Fixed content allows you to manually insert a value into an edit box using a

keyboard. The inserted value remains unchanged on every printed label.

All standard Windows editing features are supported for inserting and editing the

xed content (cut, copy, paste, etc.). Special characters are accessible via arrow

button on the right side of the edit elds or via context (right click) menu.

15

Variable If a label or form object is connected to a variable, its current value is always

displayed as the object's content. When the variable's value changes, the change

reects in the appearance of the selected object.

Create and manage multiple types of variables using the Designer's Dynamic Data

Manager tool.

Function Functions process the existing data source values and store the result in function-

generated data sources.

Designer oers multiple types of functions that allow you to transform the variable

object content according to the current needs.

Database Various types of databases can be used as dynamic data source for label or form

objects. Select a database from the list of dened database connections. When

done, select the elds and use them as a data source for an object.

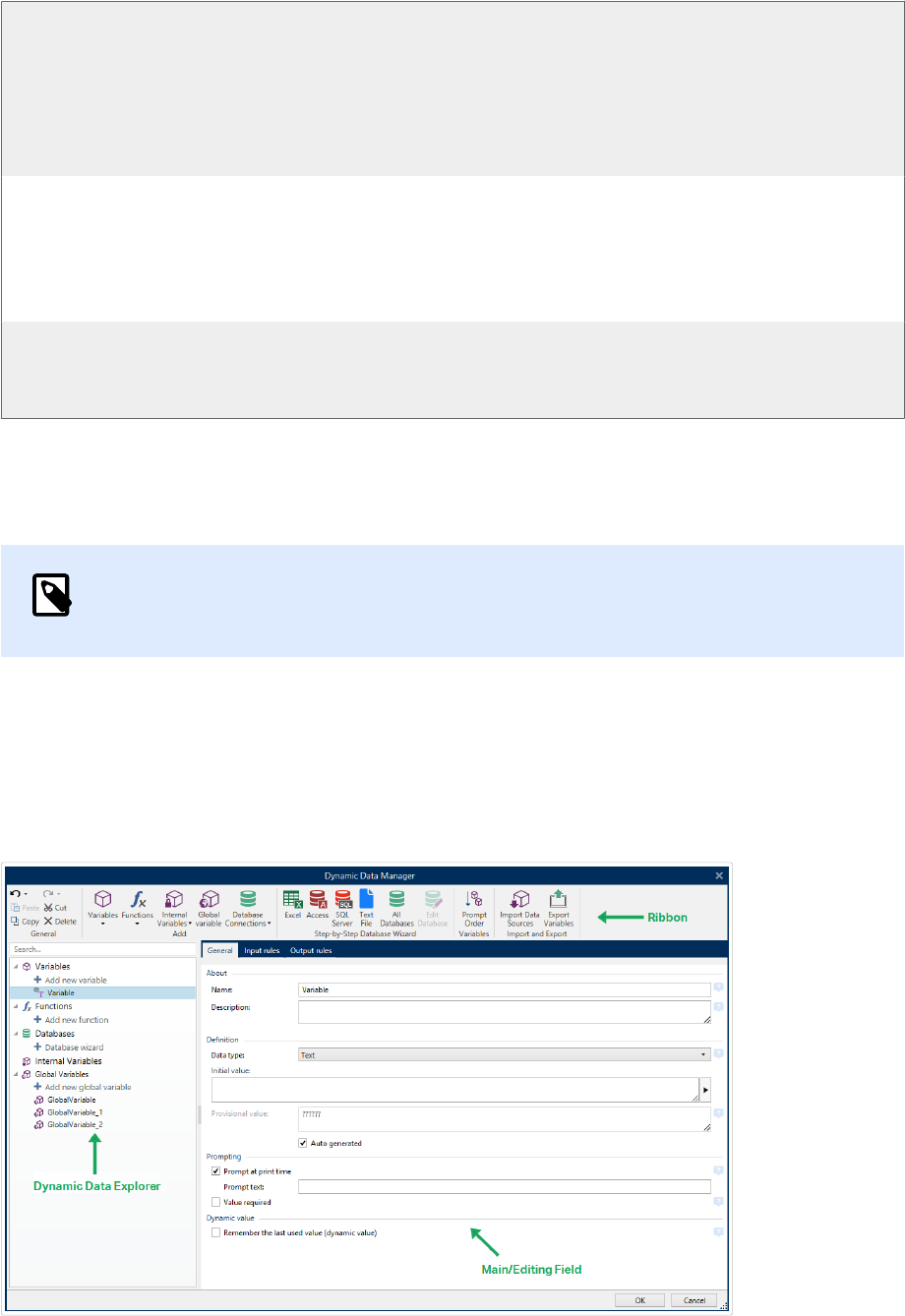

1.1.8. Dynamic Data Manager

PRODUCT LEVEL INFO

This section applies to NiceLabel 2019 Pro and PowerForms editions.

Dynamic Data Manager is a dialog that enables the user to manage the dynamic data sources for

label and form objects.

Label and form objects can be connected to multiple variables, functions and databases.

To open the dialog, click the Dynamic Data Manager button in the Designer ribbon.

Read more about how to dene the data sources in the following sections:

16

• Work with variables.

• Work with functions.

• Use databases as content source.

• Use internal variables as content source.

• Use global variables as content source.

1.1.9. Dynamic Data Explorer

PRODUCT LEVEL INFO

This section applies to NiceLabel 2019 Pro and PowerForms editions.

Dynamic Data Explorer is a Designer tool for managing the data sources that are connected to label

or form objects.

Dynamic Data Explorer is located at the bottom left side of the Designer window. It oers an overview

of existing Variables, Functions and Databases and allows adding new sources.

Read more about the Dynamic Data Explorer and how to work with it here.

1.1.10. Layers

Layers act as transparent surfaces that allow you to place your objects on labels or forms in multiple

levels.

When designing labels or forms that contain a large number of objects, layers help you manage the

positioning and visibility of added objects.

NiceLabel 2019 allows you to use layers when designing labels and forms using the Layers panel. This

helps you design adaptable label templates and create forms that align with your business logic. Read

more in section Layers Panel.

17

1.1.11. Solution Explorer

PRODUCT LEVEL INFO

This section is applicable to PowerForms.

Solution Explorer is the Designer's dedicated tool for managing the labels and forms in a solution.

Solution Explorer is located at the bottom left side of the Designer window. It displays the existing

labels and forms and allows adding new ones.

Solution and Data source buttons toggle between Solution Explorer and Dynamic Data Explorer.

1.1.12. Actions Editor

PRODUCT LEVEL INFO

This section is applicable to PowerForms.

Actions Editor is a dialog for managing actions in a Designer solution.

18

Actions can be dened for:

• Form: these actions are triggered with form events. They are applicable to the following events:

• On form load: action(s) are run after a form is loaded.

• On form close: action(s) are run after a form is closed.

• On form timer: action(s) are run after a specied time interval.

• On Form Inactivity: action(s) are run after the form has been inactive for a given time

interval.

• Form object: these actions are triggered with object-related events.

• Variable: these actions are triggered according to the received values.

1.1.12.1. Ribbon

Actions Editor Dialog ribbon includes commands for adding, removing and ordering the actions. It

also provides a direct access to frequently used actions.

Clipboard group icons activate the following actions:

• Paste: pastes the clipboard data.

• Cut: cuts the selection to the clipboard.

• Copy: copies the selection to the clipboard.

• Delete: deletes the selected items.

Undo & Redo group allows undoing or repeating actions.

• Undo: Designer allows the user to undo the entire sequence of actions since opening the editor.

19

• Redo: repeats the requested range of actions.

Action Order group denes the action execution order of selected actions.

• Up and Down: arrows place the selected action in front or after any other existing action.

• Right: arrow nests the selected action under the previous existing action.

NOTE

Nested action is any action that starts when the parent action is already in progress.

• Left: arrow makes a nested action independent of the preceding action.

NOTE

Certain actions cannot exits independently. If such action is added to the action list, a

warning appears. The warning denes which action should it be nested under.

Add assigns actions to the selected form object.

• All actions button gives access to the entire range of Designer actions. Recently used actions

are listed on the top. Use Search... eld to quickly locate any action by entering its name.

• Four buttons give direct access to the most commonly used actions:

• Open Label: button adds the Open Label action to the event list.

• Print Label: button adds the Print Label action to the event list.

• Set Printer: button adds the Set Printer action to the event list.

• Quit: button adds the Quit action to the event list.

1.1.12.2. Actions Explorer

Actions Explorer is a tool for adding, removing and ordering the assigned actions. Use ribbon

commands to manipulate with existing actions or to add new actions.

The explorer columns provide instant overview of actions' execution options and their descriptions.

• Enabled: enables or disables the included action.

• Condition: display the condition for executing an action (if set).

• Description: displays the information about an action as dened by the user.

Actions Explorer enables you to make a selection of multiple actions, and to perform copy, paste and

delete operations with them. To make a selection, Use Ctrl/Shift + Click on the required actions.

20

NOTE

Multiple actions can only be selected under the same parent action, i.e. all selected

actions must be on the same level. See picture below.

1.1.12.3. Editing eld

Editing eld allows editing the advanced action properties.

• Main properties of the selected action are available for editing on the top of the Main/editing

eld. Main properties dier with each action – read the dedicated action description sections for

details.

• About group allows you to describe all NiceLabel 2019 actions.

• Name: by default, action name is dened by its type and is therefore not unique. Dene a

custom name to make it instantly recognizable among other actions, in logs and in

potential error messages.

• Description: user notes for the selected action. Description is displayed in actions

explorer.

• Action Type: read-only eld which displays the type of action.

NOTE

When upgrading from legacy solutions (created with NiceLabel V6 and back),

update the action names based on the currently selected language. Solution

version becomes updated.

• Hidden properties dene the less frequently dened properties. Hidden properties dier with

each action – read dedicated action description sections for details.

21

1.2. Keyboard and Mouse Support

To eciently perform and complete the Designer tasks, follow the guidelines related to the use of

keyboard and mouse:

• How to eciently use keyboard and mouse

• Keyboard shortcuts

1.2.1. Ecient Use of Keyboard and Mouse

Use the following list of tips to make your work with Designer easier and more ecient.

1. Select object anchoring point. Press <Ctrl> key and click the object placeholders to quickly

dene the anchoring point.

2. Label scrolling and zooming. Use mouse wheel to scroll the label. Holding <Ctrl> when

rotating the wheel, adjusts zoom factor. <Shift> scrolls label left or right.

3. Set label or form properties. Double-click the design surface to open the label or form

properties dialog.

4. Vertical or horizontal object moving. Hold <Shift> while moving an object over the design

surface. The object is moved in straight vertical and horizontal lines.

5. Resize an object with arrow keys. Holding <Shift> while pressing arrow keys resizes the

object.

6. Fine-tune the object position. Hold <Ctrl> while pressing arrow keys.

7. Open contextual menus. Right-click the object or design surface to access the label, form or

design surface contextual menus.

8. Select multiple objects. Hold <Shift> and click the objects to add them to the selected

objects in a group.

9. Quickly add an object with connected data source. Click the object's shortcut handle in the

object toolbox. A list of available data sources appears. Select a data source or add a new

one, and click the design surface to add an object which already has a dynamic data source

connected to it.

PRODUCT LEVEL INFO:

Creation of forms and use of form objects are available in PowerForms.

22

1.2.2. Mouse Wheel Support

Use mouse wheel to speed up design object zooming and design surface scrolling.

• Turning the wheel scrolls the label in a vertical direction.

• Holding <Shift> and turning the wheel scrolls the label left or right.

• Holding <Ctrl> and turning the wheel zooms the label in or out.

1.2.3. Keyboard Shortcuts

Use keyboard shortcuts to reduce the time needed to accomplish frequent tasks with Designer. To

complete these tasks, use a standard combination of keys.

TIP

Keyboard shortcuts are just a faster and more convenient way of choosing

commands. The command itself is executed in the same way as if it was run from the

menu or toolbar.

Action

Press

Select all Ctrl+A

Run the startup form Ctrl+D

Paste Ctrl+V

Cut Ctrl+X

Move up ↑

Move right →

Move down ↓

Move left ←

Close Alt+F4

Zoom to document Ctrl+0

Bold Ctrl+B

Copy Ctrl+C

Italic Ctrl+I

Close solution Ctrl+L

Zoom Out Ctrl+minus sign on numeric keypad

Zoom In/Out Ctrl+mouse scroll up/down

Open Ctrl+O

Print Ctrl+P

23

Action Press

Zoom In Ctrl+plus sign on numeric keypad

Run the currently opened form Ctrl+R

Save Ctrl+S

Open blank label connected to default printer Ctrl+Shift+N

Redo Ctrl+Y

Undo Ctrl+Z

Cancel Esc

Move Focus Tab or Shift+Tab

Run Form Debugger when form is running Ctrl+Shift+F12

Start form and Form Debugger at the same time to

debug the onFormLoad events

Ctrl+Shift+R

Format painter – copy object properties Ctrl+Shift+C

Format painter – paste object properties Ctrl+Shift+V

1.3. Options (Conguring the Program)

PRODUCT LEVEL INFO

Solution building is available in PowerForms.

To customize the general program conguration of Designer, open the Options dialog which is

accessible from the File tab.

Designer conguration options are grouped on the following tabs:

• Folders: allows you to set the default locations for storing the labels, forms (solutions),

databases and picture les.

24

• Language: selects the user interface language. Select the preferred language from the listed

options.

• Global Variables: storage location for global variables.

• Printer usage: locally logged usage of installed printers.

• NiceLabel Control Center: allows you to enable and congure the monitoring of events and print

jobs.

• Automation: enables you to congure NiceLabel Automation settings.

• Designer: enables you to congure opening behavior of NiceLabel 2019.

25

2. Workspace Overview

PRODUCT LEVEL INFO

Data source explorer and Solution manager are available in NiceLabel Designer Pro

and PowerForms.

Your Designer workspace provides a exible and easy-to-use environment for both – simple label

designing and complex solution building.

Your Designer workspace follows widely used application interface guidelines and is equipped with

tools and interface elements familiar to most users.

Designer workspace includes the following:

• Landing page

• Object and Explorer Panels

• Layers panel

• Printer and Status bar

• Tabs and Ribbons

• Design Surface

26

2.1. Landing Page

Your landing page in Designer is an introduction which opens after the application loads. The page

includes the following:

• New document area: create new or open existing Designer documents.

• Create a New Label: create new label documents.

• New Solution: create solutions with labels and forms.

PRODUCT LEVEL INFO

Solution building is available in PowerForms.

• Open from Document Storage: open labels or solutions from Document Storage on your

connected NiceLabel Control Center.

PRODUCT LEVEL INFO

Opening from Document Storage is available when connected to

NiceLabel Control Center, and requires an LMS license.

• Open...: open existing label and solution les from your workstation, cloud or network

locations.

TIP

When you create new labels based on sample templates, Designer creates a

new folder inside your Solutions folder. Your new folder is named after your

sample. It is located at: C:\Users\username\Documents\NiceLabel

\Solutions\newly created folder

• Recent Files: lists recently used Designer les.

TIP

Your landing page and its sections are dierent when you run licensed Designer

editions or trial versions.

• Learning resources: access useful resources to help you create labels and solutions, and learn

more about NiceLabel 2019.

• Training Videos: access your NiceLabel video tutorial library. Video tutorials help you learn

label design basics and solution building in just minutes.

• User Guides: access the entire online library of NiceLabel user guides. User guides provide

you comprehensive descriptions and instructions for using NiceLabel 2019.

27

• Sample Files: access sample label collections and solution les. Use samples to get

familiar with NiceLabel 2019, start building new documents, and to explore software

capabilities. Samples help you create labels compliant with industry standards like GS1

and GHS, and labels equipped with mandatory objects like allergens or nutrition tables.

• Printer Drivers: access NiceLabel printer drivers. Drivers let you optimize your labels to print on

specic printer models.

• Software Information: contains information about your installed copy of NiceLabel 2019 –

license, license key, and installed version. If a newer version of NiceLabel 2019 is available,

notication links appear automatically. Click the link to download and install the latest version.

2.2. Object and Explorer Panels

Object and explorer panels are located at the left-most area of the Designer window. They provide

access to objects, Solution Manager and Dynamic Data Explorer.

• Object Toolbox: Contains available objects. These objects are ready to be used on a label or

form. Click the selected object and drag it to the design surface.

• Solution Manager: The tool for managing the labels and forms in a solution.

• Dynamic Data Explorer: The tool for managing the data sources in a solution.

• Layers Panel: The tool for managing the layers while you design labels or forms.

28

2.3. Layers Panel

PRODUCT LEVEL INFO

This section applies to NiceLabel 2019 Pro and PowerForms editions.

In NiceLabel 2019, the Layers panel is a tool that helps you manage your layers and added objects

while designing labels or forms.

NOTE

Layers act as transparent surfaces that allow you to place your objects on labels or

forms in multiple levels.

• Working with the Layers panel

• Positioning your objects using layers

• For easier designing: layer states

29

• Keeping layers organized using the right-click menu

2.3.1. Working with the Layers panel

• Adding a layer: Click the green plus button to add a new layer. This adds a new layer on top of

the default layer. The number of layers is not limited.

• Setting the layer properties: The Layer Properties window appears automatically when you add

a layer. Use this window to set the properties of the added layer:

• Add Name and Description to make your layers easy to nd and edit later when you add

more layers.

• The Visibility settings allow you to dene if objects on layers are visible when you print the

label, or after you run the form.

NOTE

In comparison with layer states (see section Section 2.3.3, “For easier

designing: layer states”), the visibility settings aect the layout when you

print a label, or when you run a form.

• Visible: denes if the objects on the selected layer appear on the printed label, or are

visible when you run the form.

Condition: the layer is visible if the result of the given condition is "True".

Example

You can create a single label template for labels in multiple languages. Stack the objects

with text in the required languages on the dedicated layers. Use visibility conditions to only

display the layer with the right language – in this case German.

30

• Deleting layers: Select a layer and click the red X button. This deletes the layer with all of its

objects. If the layer is locked, you cannot delete it.

• Moving layers up or down: You can change the stacking order for your existing layers. This

allows you to dene how the objects overlap. If you move one layer above another, you also

place the objects on this layer in front of the objects that belong to the layer below.

2.3.2. Positioning your objects using layers

Layers help you position label or form objects on the z-axis. This means that you can place your

objects on top or beneath the objects on other layers. If you change the stacking order of layers, you

also change the stacking order of objects.

NOTE

When designing labels or forms, the stacking order of layers tells you the vertical

position of each individual layer within all existing layers.

By default, you add all objects on a single layer. If you decide to add more layers, you can move your

objects onto newly added layers, or move objects from one layer to another at any time.

To add objects to a specic layer, click the layer in the Layers panel to make the layer active, and drag

the objects onto the currently active layer.

NOTE

You can only group the objects that belong to the same layer. To group objects from

multiple layers, move these objects onto the same layer rst.

2.3.3. For easier designing: layer states

Layer states allow you to show/hide, lock/unlock, or highlight your layers.

31

NOTE

Layer states only aect the label template or form layout during the design phase.

After printing a label or if you run a form, the layers remain visible even if you set their

state to invisible, locked, or highlighted. Manage the nal visibility of layers using the

Visibility settings in the Layer Properties window.

Layer states allow you to:

• Keep the layer visible or hide the layer. Toggle the states to make all layer objects visible or

hidden while you are designing your label template or form.

NOTE

The ability to show or hide a layer helps you position the objects that appear

above or below other objects.

• Unlock or lock the layer. If you lock a layer, you cannot:

• Add objects to this layer.

• Move objects from other layers to this layer.

• Change the position of the existing objects.

• Delete this layer.

NOTE

Layer locking prevents unwanted layout changes.

• Set focus on the layer. Use this option to determine which objects are on this on this layer by

defocusing the objects that belong to other layers. If you hover over the focus icon with your

mouse pointer, the objects on this layer remain visible, while all other objects become semi

transparent.

32

2.3.4. Keeping layers organized using the right-click

menu

Right-clicking a layer opens the contextual menu which helps you manage the layers of your label or

form:

• New layer adds a layer on top of the existing highest layer.

• Copy makes a copy of the selected layer and all of its objects.

• Paste pastes the copied layer.

• Duplicate allows you to duplicate the selected layer with a single click.

• Rename allows you to change the name of the selected layer.

33

NOTE

By default NiceLabel 2019, names the layers as Layer_"number" where "number"

tells you the initial stacking position of the layer.

• Hide Other Layers makes all layers with their objects invisible, except for the selected layer.

• Show All Layers makes all layers with their objects visible.

• Lock Other Layers makes only the selected object editable. This option locks the objects on all

other layers.

• Unlock All Layers makes all layers editable.

• Move Up/Down allows you to change the stacking order for the selected layer. Note that the

layers panel represents the stacking order of the layers. Use Move Up/Down to change the

position of the highlighted layer.

• Merge Down moves the objects from the selected layer to the layer below. NiceLabel 2019

places the moved objects on top of the existing objects and deletes the merging layer.

• Merge visible unlocked layers moves the objects from all unlocked layers to the lowest unlocked

layer. Objects from the upper layers are placed on top of the objects that belong to the lowest

layer. NiceLabel 2019 deletes the merging unlocked objects.

• Properties opens the Layer Properties window.

2.4. Objects Panel

In Designer, your Objects panel lists every object on your design surface, making it simple to nd and

select exactly the objects you want on your label templates or forms. You can search and organize

your objects within layers, both separately or in groups. Each layer shows your objects and object

groups in a tree structure.

Use your Objects panel to:

• Search for objects by name or by connected data sources.

• Display action indicator icons after object names when your objects have actions assigned.

• Rename objects (when you press F2 on your keyboard).

NOTE

When searching, press Enter on your keyboard, Object panel automatically selects the

rst object within your search parameters.

You can move up and down between objects with your keyboard arrows.

34

Additional options in your object's context menu (right-click on objects or object names) include:

• Copying, cutting, and deleting your objects or object groups.

• Locking or unlocking your objects or object groups.

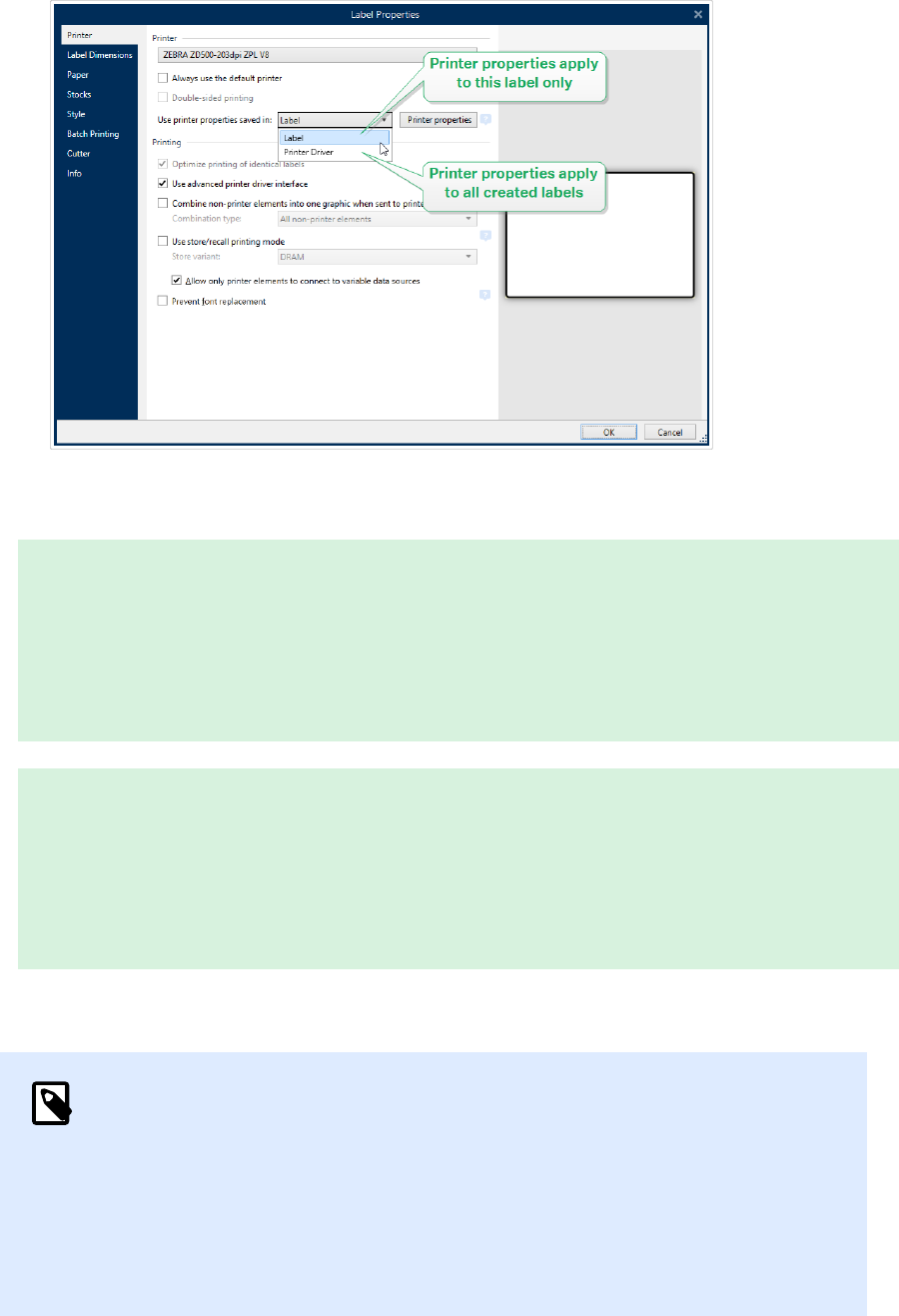

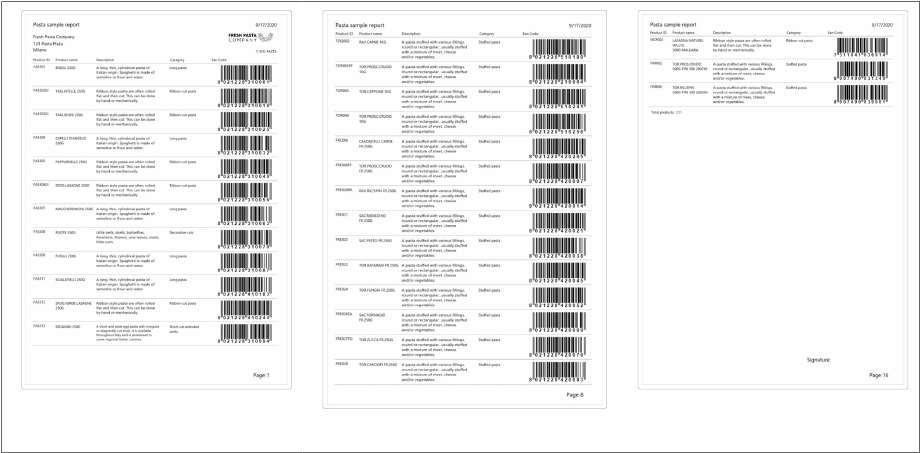

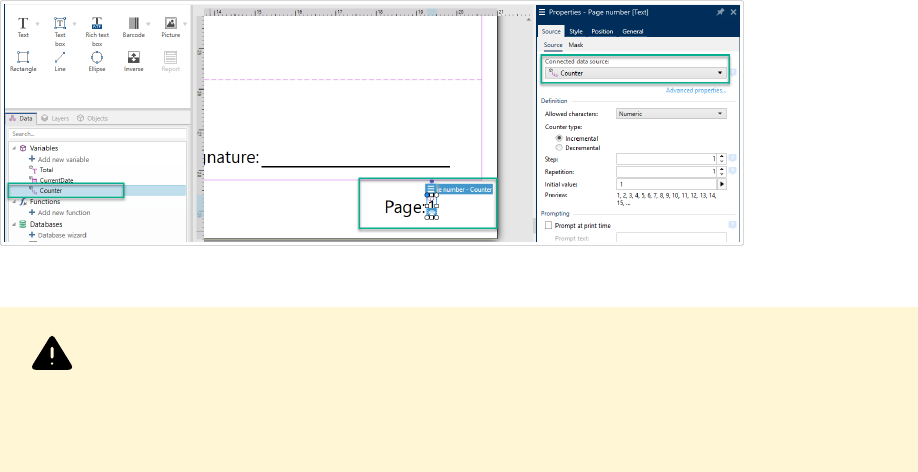

• Arranging and aligning your objects or object groups.