Oregon Harvested Wood Products Carbon

Inventory 1906 – 2018

Todd A. Morgan, Thomas S. Donahue, Thale Dillon

University of Montana, Bureau of Business and Economic Research, Forest Industry Research

Program

Andrew Yost

Oregon Department of Forestry

Jeremy Groom

Groom Analytics, LLC

April 2020

Prepared for:

USDA Forest Service, Forest Inventory and Analysis Program

Portland, OR

and

Oregon Department of Forestry

Salem, OR

Report completed through Agreement No. 18-CO-11261979-074 between the U.S. Forest

Service, Pacific Northwest Research Station and the Oregon Department of Forestry; and

Agreement No. 18-CR-11261979-095 between the U.S. Forest Service, Pacific Northwest

Research Station and the University of Montana, Bureau of Business and Economic Research.

2

Acknowledgements

The authors wish to acknowledge funding from the Oregon Department of Forestry and support

from the Pacific Northwest Research Station Forest Inventory and Analysis Program analyst

Glenn Christensen. The authors also thank CalFire research program specialist Mark

Rosenberg; Utah State University’s programmer/analyst Chris Garrard; research forester Nate

Anderson of the Forest Service’s Rocky Mountain Research Station; Dan Loeffler; and the

University of Montana’s Bureau of Business and Economic Research senior research associate

Eric Simmons for their assistance with this project. The authors also acknowledge the critical

reviews of the manuscript from four independent reviewers.

3

Introduction: Forest Carbon Accounting in Oregon

Forest ecosystems are an important and dynamic component of the carbon cycle. While

reducing emissions from combustion of geologic sources of energy (e.g., coal, oil, and natural

gas) remains the most effective and direct way for humans to control rising levels of

atmospheric carbon (Holl and Brancalion 2020), managing forests to increase carbon

sequestration and storage is often cited as a major element in addressing the climate crisis

(McKinley et al. 2011). Understanding the capacity for forests to mitigate fossil fuel emissions

requires a reliable inventory of the stock and flux of carbon in forests and the wood products

generated from timber harvesting. Indeed, there has been a decades-long demand for a reliable

forest carbon accounting framework in Oregon to better inform forest managers about the

capacity for increasing carbon sequestration and storage. For example, legislation passed as

early as 2001 required the State Forester to develop a forest carbon accounting system (ORS

526.783). Through the 2011 Forestry Program for Oregon, the Board of Forestry established

goals for developing a system for monitoring carbon in forests and harvested wood products

(HWP). Further, the Oregon Global Warming Commission (OGWC) was mandated to track and

evaluate the carbon sequestration potential of Oregon’s forests and the carbon stored in tree-

based building materials (ORS 468A.250(1)(i)). More recently, the Forest Carbon Accounting

Report (OGWC 2018) described Oregon’s long-standing need for a reliable forest carbon

accounting system to monitor the status and trends of carbon storage and annual changes (flux)

in carbon storage in forest ecosystems and HWP.

Recognizing the need for proper forest carbon accounting in Oregon, the Forest Ecosystem

Carbon Report (Christensen et al. 2019) presented the forest ecosystem dimension of the

accounting framework. That report provided estimates of the amount of carbon stored in seven

pools of forest carbon based on the Forest Inventory and Analysis (FIA) Program’s annual

inventory of field plots distributed across Oregon’s forests. These were initially measured from

2001 to 2010. The report also provided estimates of the amount of carbon flux to and from those

pools based on measurements of the same field plots revisited from 2011 to 2016. Estimates of

forest carbon flux in the ecosystem report were based on calculations of tree growth, mortality,

and removals between the two periods. The report was a result of a partnership between the

Governor’s Office of Carbon Policy, Oregon Department of Forestry (ODF), and the Pacific

Northwest Research Station (PNW) of the USDA Forest Service.

Reliable estimates of stocks and flux of carbon in forest ecosystems and HWP provide a basis

for analyses of tradeoffs between carbon storage and other forest management objectives,

which can inform forest managers, policy-makers, and the public (Galik and Jackson 2009,

Ryan et al. 2010, McKinley et al. 2011). Although HWP C constitutes a relatively small fraction

of forest carbon relative to ecosystem carbon (Loeffler et al. 2019), it is a fundamental

component of carbon accounting and base of information for evaluating various strategies to

reduce atmospheric carbon dioxide (CO

2

) concentrations.

Forest C removed by timber harvest is not released immediately into the atmosphere because

timber harvests transfer a portion of the C stored in wood to a "product pool." Once in a product

pool, the C is emitted over time mostly in the form of CO

2

as it decomposes. When discarded

wood products are burned, other greenhouse gases (CH

4

, N

2

O, CO, and NOx) are emitted. The

4

rate of emission varies considerably among different product pools. For example, if timber is

harvested for fuelwood to produce energy, combustion releases C immediately but if timber is

harvested and used as lumber in a house, it may be many decades or even centuries before the

lumber decays and C is released to the atmosphere. If wood products are disposed of in solid

waste disposal sites (SWDS), the C contained in the wood may be released many years or

decades later or may be stored almost permanently in SWDS (EPA 2020).

This report provides estimates for the storage and flux of carbon in wood products

manufactured from trees harvested in Oregon since 1906 (Andrews and Kutara 2005, Simmons

et al. 2016). It was made possible through a partnership with ODF, PNW-FIA, and the Bureau of

Business and Economic Research (BBER) at the University of Montana.

Objectives

The objectives of this analysis were to:

1) Use the production accounting approach to generate estimates and confidence intervals

for the stocks and flux of carbon in the HWP pool for timber harvested from 1906 to 2017

within the State of Oregon.

2) Generate estimates and confidence intervals for the cumulative emissions of CO

2

from

burning fuelwood for energy capture and from the decay and burning of discarded wood

products.

3) Compare the amount of carbon in HWP among the major Oregon forest ownerships that

contributed harvested timber to the pool of HWP from 1962-2017 harvests.

4) Combine the estimate of stock and flux for the HWP pool with the average in Oregon’s

forest ecosystems to evaluate the total stocks and flux in forests and HWP from 2001-

2016.

5) Provide a reporting framework for subsequent HWP C analyses in Oregon that can be

applied to other regions with available timber harvest and end-product data.

This report neither advocates any particular course of action for forest carbon management, nor

does it include a life-cycle analysis (LCA) of wood products, estimates for the substitution

benefits of wood products, leakage, or estimates of greenhouse gas emissions associated with

timber harvesting, wood products manufacturing or related transportation.

Methods

Harvested wood products include lumber, panels, paper, paperboard, and wood used for fuel,

and the HWP C pool includes both products currently in use, products-in-use (PIU), and

products that have been discarded to SWDS. Additions to the HWP C pool are made through

5

harvesting timber for wood products, and emissions that occur from the decay and combustion

of wood products subtract from the pool.

The HWP C analysis described in this paper was based on timber harvested and processed in

the State of Oregon, as well as timber that was harvested in Oregon and processed (or burned

as fuelwood) outside the state. It does not include timber from outside Oregon that was

processed by Oregon facilities (mills) or used directly by residents of Oregon. Material left in the

forest after harvest (i.e., logging residue) is not accounted for in this report as HWP C but can

represent approximately 32% of total tree biomass as treetops, branches, and foliage (Ganguly

et al. 2020).

Nearly all (over 99%) of the bark on logs delivered to primary processing facilities is burned for

energy or used for mulch and other landscaping products (Brandt et al. 2006, Simmons et al.

2016, Simmons et al. 2019). Therefore, bark is considered a short-lived by-product with

negligible contribution to the pool of HWP C. Nevertheless, approximations were made for the

amount of biogenic emissions occurring from utilization of bark following Harmon (1996).

Oregon records timber harvest with the Scribner decimal c log rule (32-foot log West OR, 16-

foot log East Oregon), which uses inside-bark measurements to quantify wood volume. Total

harvest volumes were converted from board foot volumes to cubic feet based on the conversion

factors listed in Table 1 (page 8) and the carbon in bark was approximated with the following

equation:

= ×

1

All timber harvested in a specific year is utilized as PIU, SWDS or fuelwood for energy capture

throughout the year of harvest with the final amounts for each pool reported in the subsequent

year. The model will generate estimates for emissions with energy capture from discarded wood

products when reliable information for parameterization becomes available.

Model

As pointed out by Stockmann et al. (2012) and Loeffler et al. (2019), monitoring systems for

HWP C have been implemented at the national level. There are well-established and robust

inventory-based methods for estimating carbon stocks and fluxes in forest ecosystems, with

several tools available to forest managers (Galik et al. 2009, Smith et al. 2004, Smith et al.

2006, Zheng et al. 2010). However, some of these tools, such as the U.S. Forest Carbon

Calculation Tool (Smith et al. 2006), do not provide estimates of HWP C, while others, such as

WOODCARB II (Skog 2008) are restricted to national level HWP C accounting. Neither of these

models are accessible or practical tools for estimating and monitoring stocks and fluxes in HWP

C at the state level (Ingerson 2011, Stockmann et al. 2012).

6

Estimates of HWP C for the state of Oregon were calculated using the Intergovernmental Panel

on Climate Change (IPCC) Tier 3 production accounting approach

1

, which only considers timber

harvested in a particular area of study. The HWP C model has been used by several National

Forest System (NFS) regions to quantify carbon stored in wood products manufactured from

NFS timber (Anderson et al. 2013, USURS 2013, Butler et al. 2014, Loeffler et al. 2014,

Stockmann et al. 2012). It has also been used to produce state-specific estimates for California

(Loeffler et al. 2019). The software to run the HWP C model was programmed in R by Groom

Analytics and available online at www.ODF.gov

.

The HWP C model uses a series of calculations to estimate carbon storage and emissions for

timber that is harvested and used for wood products. Stockmann et al. (2012) provide a flow

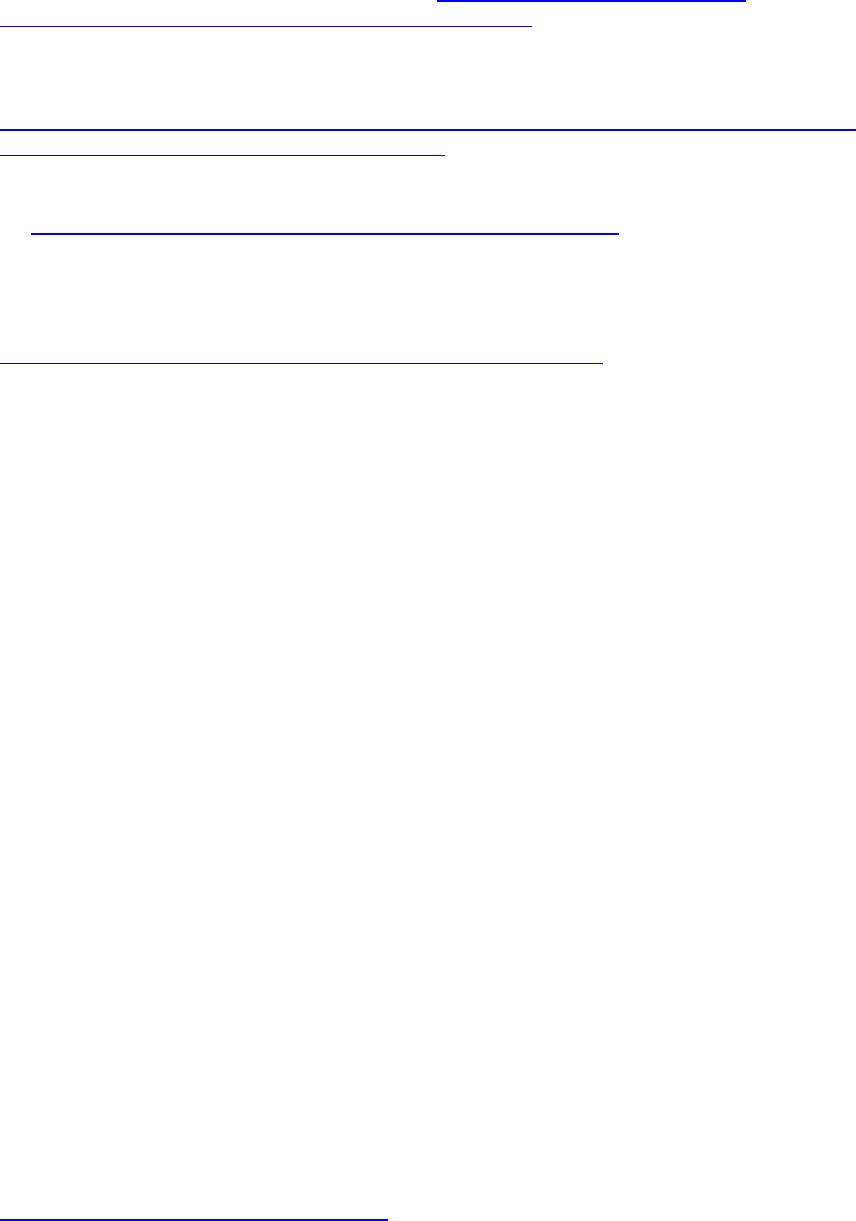

chart of the model (Figure 1) demonstrating how HWP C is tracked through a product’s life, from

timber harvest through timber products, primary wood products, end use products, and finally to

disposal. For a more detailed description of the model assumptions and calculations, see

Stockmann et al. (2012) and Loeffler et al. (2019).

Figure 1. Diagram of the harvested wood products model used to quantify carbon

storage pools and emissions.

Source: Stockmann et al. 2012

1

IPCC Tier 3 denotes the availability of highly detailed data (e.g., from field plots) and the use of simulation models,

whereas Tier 1 and 2 use more general data that result in higher uncertainty.

7

Four sets of inputs are required to run the HWP C model: 1) annual timber harvest volume; 2)

annual timber product ratios that allocate harvest to different timber product classes; 3) annual

primary product ratios allocating the timber products to a variety of primary products and residue

uses, and 4) end use ratios that allocate the primary products to a larger set of end use

products. For this Oregon HWP C analysis, the input files were developed from Oregon-specific

data, the sources for which are outlined below.

Data Sources

Timber Harvest Data

Data for Oregon’s timber harvest volume is quite extensive but somewhat incomplete for the

earliest years. Andrews and Kutara (2005) compiled state-level harvest volumes going back to

1925 and state-level lumber production as far back as 1849. County-level timber harvest data

with three ownership classes (Tribal, U.S. Forest Service [USFS], private and state combined)

have been compiled since 1953, and with the seven ownership classes currently in use

(industrial private, non-industrial private [NIP], Tribal, State, Bureau of Land Management

[BLM], USFS, and other public) since 1962. Both classifications are from the Oregon

Department of Forestry (Andrews and Kutara 2005, ODF 2019). The earliest vintage allowed by

the HWP C model is 1906 because it was originally developed for use by the NFS, which was

transferred to the Department of Agriculture’s U.S. Forest Service in 1905.

Estimates of Oregon timber harvest volumes without ownership classifications are available

from 1906 to 1961. Harvest volumes by ownership are available for a shorter time—from 1962

to 2017—allowing for an ownership-level analysis for this period. The major limitation

associated with the data for years prior to 1962 is the absence of reliable harvest data for each

ownership and the lack of quantitative information from mill studies necessary for developing

timber product and primary product ratios for each ownership.

The five ownership classes reported in this analysis include USFS, BLM, Tribal, Private

(including industrial and non-industrial lands) and State and other public (including ODF and

other state lands, county and municipal lands). See Appendix 1, table 1A, for Oregon timber

harvest by ownership class. State-level Oregon timber harvest data for 1906 to 2017 are

included in Appendix 1, table 1B.

Because it was originally developed for use by NFS, the HWP C model requires timber harvest

input files with volumes expressed in hundred cubic feet (ccf). Timber harvested in Oregon were

reported in a mix of thousand board feet (mbf) Scribner, log rule and mbf lumber tally (Andrews

and Kutara 2005) and were converted to cubic feet (cf) of logs using conversion factors from

literature and an ordinary least squares regression equation (r-square = 0.9871) formulated

from published bf/cf factors (Table 1).

8

Timber Product and Primary Product Data

Oregon harvest and mill studies (Andrews and Cowlin 1940; Cowlin et al. 1942; Metcalf 1965;

Manock et al. 1970; Schuldt and Howard 1974; Howard and Hiserote 1978; Howard 1984;

Howard and Ward 1988, 1991; Ward 1995, 1997; Ward et al. 2000; Brandt et al. 2006; Gale et

al. 2012; Simmons et al. 2016) were used to develop ratios for timber products (e.g., softwood

sawlogs, softwood pulpwood, etc.) and primary products (e.g., softwood lumber, softwood

plywood, softwood mill residue used for energy, etc.). For years when specific product ratios

could not be determined from the literature, ratios from the previous or following mill study year

were used.

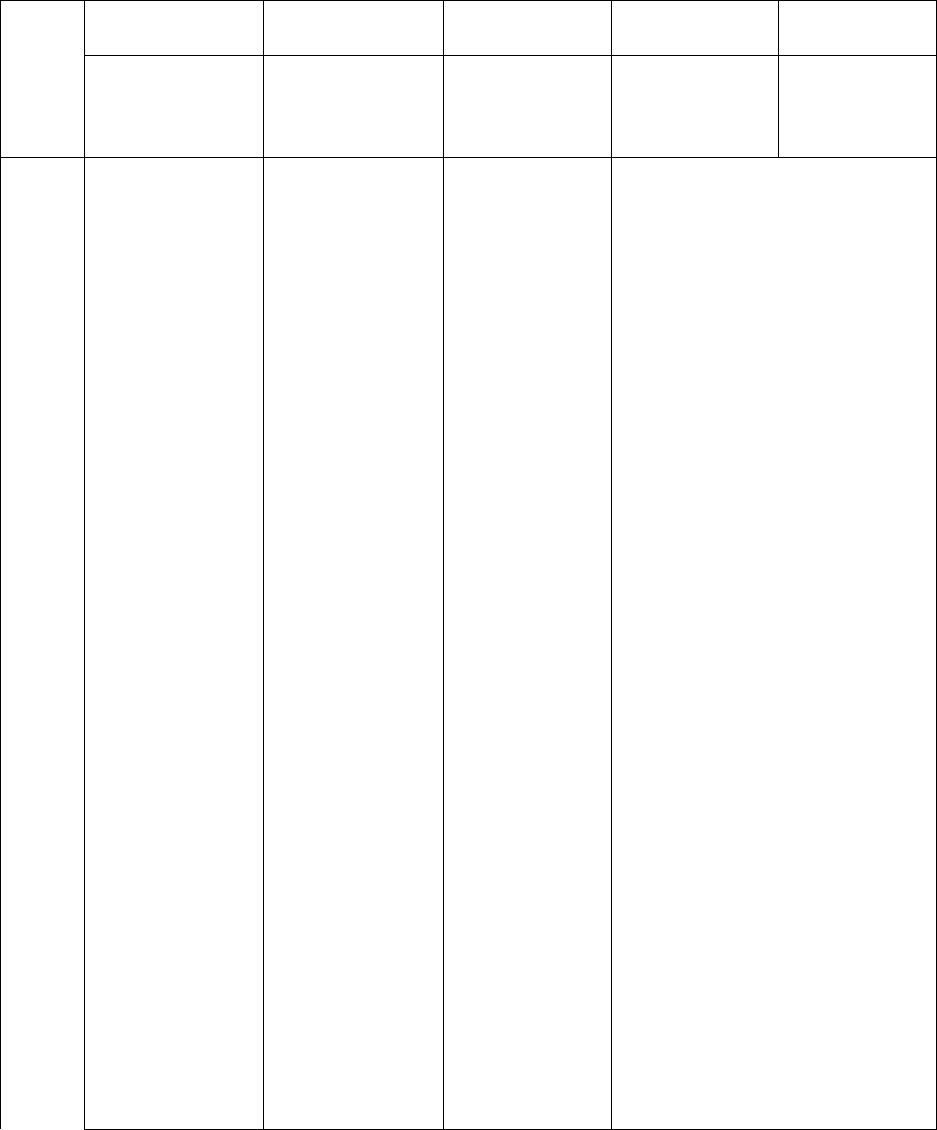

Table 1. Conversion factors used in the Oregon HWP C analysis

Conversion Units Source

8.596 bf per cf, timber harvest 1906 – 1910

Regression Equation

8.141 bf per cf, timber harvest 1911 – 1920

7.6923 bf per cf, timber harvest 1921 – 1930 Andrews and Cowlin (1940)

7.231 bf per cf, timber harvest 1931 – 1940

Regression Equation

6.776 bf per cf, timber harvest 1941 – 1950

6.321 bf per cf, timber harvest 1951 – 1960

5.866 bf per cf, timber harvest 1961 – 1970

5.42 bf per cf, timber harvest 1971 – 1979

Keegan et al. (2010)

5.17 bf per cf, timber harvest 1980 – 1989

4.55 bf per cf, timber harvest 1990 – 1999

4.0674 bf per cf, timber harvest 2000 – 2003 Brandt et al. (2006)

4.1813 bf per cf, timber harvest 2004 – 2008 Gale et al. (2012)

4.0161 bf per cf, timber harvest 2009 – 2017 Simmons et al. (2016)

33 to 42 lbs per cubic foot, primary products

Smith et al. (2006)

2204.6 lbs per metric ton (MT)

0.95 to 1.0 Metric ton wood fiber per metric ton product

0.5 Metric ton carbon (MT C) per dry metric ton wood fiber

0.71 to 0.91 MT C per ccf, primary products

1

1

See Appendix 1, table 1C (embedded .pdf file), for the model’s ccf to MT C conversion for each primary product.

The model utilizes 40 timber product classes (Appendix 1, table 1D embedded .pdf file),

requiring harvest to be allocated to timber product categories. Since Oregon timber harvest

records contain only harvest volume and do not allocate harvest among different timber product

types, harvest and mill studies that quantified the volume of timber used for different products

were used to calculate the proportion of total timber harvest that went into each timber product

category. Quantitative information from two published reports for the period 1906 to 1941 was

9

used to develop timber product ratios for timber from the Douglas-fir and ponderosa pine

regions of Washington and Oregon (Andrews and Cowlin 1940, Cowlin et al. 1942). Timber

product ratios were developed from Metcalf (1965) for the period 1942 to 1961.

Data for developing timber product ratios for harvest after 1961 were more readily available

2

.

The portion of the harvest allocated to each timber product class was calculated for each

harvest year for which data were reported. Although there are 40 timber product classes in the

model, the majority of harvested timber was softwood sawtimber for both periods (Table 2). See

Appendix 2, embedded .pdf file A, for Oregon timber product ratios from 1906 to 2017.

Table 2. Average annual Oregon timber product ratios, 1906-1961 and 1962-2017.

Products class

1906 to 1961 1962 to 2017

Mean Std. deviation Mean Std. deviation

Sawtimber, hardwood

0.003

0.001

0.016

0.010

Sawtimber, softwood

0.818

0.030

0.921

0.061

Pulpwood, hardwood

0.002

0.002

0.011

0.013

Pulpwood, softwood

0.034

0.035

0.042

0.040

Poles, softwood

0.003

0.000

0.004

0.002

Fuelwood, softwood

0.128

0.004

0.002

0.017

Other

0.012

0.010

0.004

0.004

There were 64 primary product classes with ratios, developed from the USFS Pacific Northwest

Region HWP C report (Butler et al. 2014) used for the 1906 to 1941 period, and Oregon-specific

primary product ratios developed from Manock (1970) that were used for 1942 to 1961. For

1962 and later, primary product ratios were developed from the same literature used to

calculate timber product ratios

3

. Mill residues are included as primary wood products, with some

entering solid waste disposal sites (SWDS) immediately, some being burned for energy, and

some being converted into products that rely on mill residues as raw material, such as

particleboard and paper. See Appendix 2, embedded file B, for Oregon’s primary products ratios

1906 to 2017. Estimates of primary products volume (in ccf) were converted to metric tons of

carbon (MT C) using product specific conversion factors (Smith et al. 2006; Appendix 1, table

1C, embedded .pdf file)

2

Metcalf 1965; Manock et al. 1970; Schuldt and Howard 1974; Howard and Hiserote 1978; Howard 1984; Howard

and Ward 1988, 1991; Ward 1995, 1997; Ward et al. 2000; Brandt et al. 2006; Gale et al. 2012; Simmons et al. 2016.

3

Manock et al. 1970; Schuldt and Howard 1974; Howard and Hiserote 1978; Howard 1984; Howard and Ward 1988,

1991; Ward 1995, 1997; Ward et al. 2000; Brandt et al. 2006; Gale et al. 2012; Simmons et al. 2016.

10

End-Use Data

The fate of HWP C is highly dependent on the end use of the primary products. For example,

the release of carbon from lumber used in new home construction has a longer duration than

carbon released from lumber used for shipping containers, which is released into the

atmosphere more quickly through combustion and decay. Fuelwood products are assumed to

have full emissions with energy capture in the year they were produced.

Following the methodology advanced by Stockmann et al. (2012) and Loeffler et al. (2019),

annual primary product output is distributed to specific end-use categories within the HWP C

model according to annual wood product consumption estimates (McKeever 2009, McKeever

and Howard 2011). The model’s primary products and corresponding end use categories are

shown in Appendix 1, table 1E (embedded .pdf file). A national data set was used for a series of

analyses and reports generated for all NFS Regions (USFS 2019) for the distribution of primary

products to end uses (Appendix 2, embedded .pdf file C).

The HWP model has 224 different possible end uses for HWP per harvest year (e.g., softwood

lumber/new housing/single family, softwood lumber/new housing/multifamily, softwood

lumber/new housing/manufactured housing, softwood lumber/manufacturing/furniture, softwood

lumber/packaging and shipping, etc.). The amount of carbon remaining in use during each

inventory year was calculated based on the products’ half-lives (Appendix 2, embedded file D)

and the number of years that have passed between the year of harvest and the inventory year.

An end-use product’s half-life value is the decay rate at which carbon in the PIU category

passes into the discarded-products category, representing the transition between the two pools

(Appendix 1, table 1F, embedded .pdf file). The amount of HWP C remaining in use in any given

year was calculated for each end use from all prior years with the standard decay formula:

=

exp (

()

/

)

where N

t

is the amount of carbon remaining in use in inventory year t, N is the amount of carbon

in the end use category in the vintage year of harvest, t is the number of years since harvest, t

1/2

is the half-life of carbon in that end use, and exp is notation for the exponential function. In our

calculations, the starting amount (N

0

, at n=0) is adjusted downward by an 8% loss factor

(McKeever 2004, Skog 2008) to reflect an immediate transfer to the pool of discarded products

before entering the PIU pool. This “loss in use” accounts for waste when primary products (e.g.,

softwood lumber) are put into specific end uses (e.g., new single-family residential housing).

For a given inventory year, the balance of HWP C that is not in use and not emitted with energy

capture is assumed to be in the discarded products category. Carbon in discarded products falls

into one of five disposition categories: burned, recovered, compost, landfills and dumps

4

. The

proportion of discarded products that ends up in each of these five categories is different for

paper vs. solid wood products, and changes over time. Prior to 1970, wood and paper waste

were generally discarded to dumps, where it was subject to higher rates of decay than in

4

Dumps are open-air disposal sites with high decomposition rates, while landfills are environments with lower decomposition rates.

11

modern landfills. Since then, the proportion of discarded wood and paper going to dumps has

dropped, while the proportion going to landfills has risen, with the remainder going to the other

two disposition categories, composting and recovery. Composting and recovery (i.e., recycling

and reuse) have become a more prominent part of contemporary waste management systems.

In the HWP C model, carbon in compost is assumed to transition directly to emissions while

carbon in recovery has a half-life decay factor that treats the discarded portion as emissions.

The model’s disposal of carbon in paper and solid wood products to dumps and landfills

categories is based on discarded products disposition ratios (Appendix 2, embedded file E) from

Skog (2008). Following the passage of the Resource Conservation and Recovery Act of 1976

(RCRA, 42 USC § 6901), a much larger portion of discarded HWP goes into modern landfills

rather than aerobic dumps or disposed through open burning, which were the dominant form of

SWDS prior to RCRA. The model assumes that carbon from discarded products that are burned

or composted is emitted without energy capture due to a lack of reliable data to support the

alternative (Stockmann et al. 2012, Loeffler et al. 2019). Carbon in the recovered category re-

enters the PIU category in the year of recovery. Carbon in products discarded to landfills and

dumps are subject to decay determined by their respective half-lives. Only a fraction of the

discarded products pool in landfills is subject to decay and associated with emission of carbon.

The portion of the discarded products pool not subject to decay is considered “fixed carbon”

(Appendix Table 1F embedded .pdf file). For a given year, the carbon remaining in SWDS is the

sum of fixed carbon and the carbon remaining after decay.

The HWP C model calculates and reports HWP C stock reductions (i.e., emissions) in MT C,

and does not estimate the different forms of C emissions (e.g., as methane, carbon monoxide,

carbon dioxide, etc.). Estimates for carbon emissions from HWP were multiplied by the atomic

weight of carbon dioxide divided by the atomic weight of carbon (i.e., 44/12) to find the carbon

dioxide equivalent (CO

2

e). All landfill and dump emissions are considered emissions without

energy capture. Methane remediation that includes combustion and subsequent emissions with

energy capture at landfills is not modelled. These methods are used to calculate annual HWP C

in the PIU and SWDS pools and emissions for all inventory years from 1906 through 2017.

Uncertainty Analysis

A Monte Carlo (MC) simulation analysis was conducted to estimate the uncertainty associated

with estimates generated with the HWP C model following methods described by Skog (2008)

and used by Anderson et al. (2013) and Stockmann et al. (2012). The goal of the MC simulation

was to produce 90% confidence intervals for the cumulative amount of carbon classified in four

categories: SWDS, PIU, emissions without energy capture (EWOEC), and emissions with

energy capture (EEC) from fuelwood. To achieve this goal, the MC simulation directly altered 16

different variables within the model according to their associated parameters (Appendix 3, table

3a). These 16 variables were allowed to vary by amounts that were based on estimates from

Skog (2008) and professional judgement. Random values were drawn from triangular

distributions that have a peak value of 1.0 (Appendix 3, table 3a) and symmetrically taper to

given 90% confidence interval bounds. The random values from the triangular distribution were

used as proportions for adjusting parameter values for each iteration of the simulation. A full

12

description of the methods for the MC simulation is provided in Appendix 3. Software to operate

the HWP C model and MC simulation was written in the R (2020) programming environment.

Results

Estimates of HWP C stocks and flux for Oregon’s timber harvests from 1906 to 2017 are

reported below, followed by results of the uncertainty analysis. Next, HWP C estimate at the

ownership level are reported for the 1962 to 2017 harvest period. Finally, HWP C stock and flux

estimates are evaluated with results from the Oregon Forest Ecosystems Carbon Report

(Christiansen et al. 2019).

State-wide HWP Carbon Stocks and Flux, 1907–2018

Changes in Oregon’s timber harvest levels by county and ownership have been well

documented (Andrews and Kutara 2005, ODF 2019). Recent trends in harvest ownership,

species, and product mix have been discussed in the context of wood products markets, and

the broader economy, as well as changing forest policy and industry infrastructure (Brandt et al.

2006, Gale et al. 2012, Simmons et al. 2016). The analysis that follows focuses on the

consequences of Oregon’s dynamic timber harvest levels and national wood use and disposal

on the stock and flux of HWP C since 1906. Timber product output (TPO) refers to the quantity

of carbon in harvested timber as estimated by the model.

In 1906, annual TPO was approximately 1.3 MMT C and grew to 5.1 MMT C by 1929 (Figure 2).

Timber harvest steadily increased, after dropping to 1.8 MMT C of TPO in 1932, with greater

demand for wood products during World War II and the housing boom that followed (Andrews

and Kutara 2005, Brandt et al. 2006).

13

Figure 2. Annual and cumulative timber product output (TPO) in MMT C from Oregon's

forests, 1906-2017.

Annual TPO reached a peak in 1972 at 13.3 MMT C and decreased to 8.2 MMT C by 1981 from

three recessions between 1973 and 1982. Annual TPO recovered to 12.5 MMT C in 1986

before its descent during the 1990s when the USFS timber harvest dropped steeply with

implementation of the Northwest Forest Plan (Spies et al. 2019). Recent notable changes

occurred around the Great Recession in 2009, when annual TPO and harvest declined by one-

third, to less than 5.1 MMT C, before rebounding to pre-recession levels of 7.6 MMT C in 2014

(Table 3). In 2017, the last year of timber harvest data at the time of analysis, annual TPO was

7.1 MMT C, and cumulative TPO was 814.4 MMT C (Table 3).

The carbon in TPO is added to the pool of HWP carbon as PIU, which consists of all 224 end-

use products. The carbon in the PIU pool matriculates into the SWDS pool and is emitted to the

atmosphere as wood decays, is burned as fuelwood for energy capture, or burned without

energy capture. For instance, the 1962 total harvest volume of approximately 8.5 bbf Scribner

represented TPO of 10.7 MMT C, with about 7.2 MMT C added to the PIU pool and about 11.4

MMT CO2e emitted from burning fuelwood and wood disposal.

0

150

300

450

600

750

900

1,050

0

2

4

6

8

10

12

14

1906

1910

1914

1918

1922

1926

1930

1934

1938

1942

1946

1950

1954

1958

1962

1966

1970

1974

1978

1982

1986

1990

1994

1998

2002

2006

2010

2014

Cumulative TPO MMT C

Annual TPO MMT C

TPO_MMTC

CumTPO_MMTC

14

Table 3. Oregon timber harvest, timber product output (TPO) and cumulative TPO, 2000-

2017.

Harvest year Timber harvest Timber product output Cumulative TPO

bbf Scribner

MMT C

MMT C

2000

3.9

7.0

696.0

2001

3.4

6.3

702.3

2002

3.9

7.2

709.4

2003

4.0

7.3

716.8

2004

4.5

7.9

724.7

2005

4.4

7.8

732.5

2006

4.3

7.7

740.2

2007

3.8

6.7

746.9

2008

3.4

6.1

753.1

2009

2.7

5.1

758.1

2010

3.2

6.0

764.1

2011

3.6

6.7

770.8

2012

3.7

6.9

777.8

2013

4.2

7.8

785.5

2014

4.1

7.6

793.1

2015

3.8

7.0

800.1

2016

3.9

7.2

807.3

2017

3.9

7.1

814.4

See Appendix 1, table 1B, for all annual harvest and TPO data years.

Carbon in PIU is held in end-use or recovered products, and carbon in SWDS is held in landfills

or in dumps. Over time, stored carbon is emitted with energy capture (e.g., using fuelwood for

energy) or without energy capture (i.e., emitted from landfills, dumps, recovered products,

burning and compost). Emissions from the burning of discarded products with energy capture

are treated as zero in this report because reliable data were not available to parameterize that

portion of the HWP model (Appendix 2, embedded .pdf file C). Approximately 1,700.5 MMT

CO2e (463.8 MMT C) was emitted through combustion and decomposition of wood products

since 1906 (Table 4). Thus, total biogenic emissions from HWP account for 56.9% of cumulative

TPO. The cumulative HWP stock was 350.7 MMT C, about 43.1% of cumulative TPO since

1906. Products-in-use account for 57.3% (201.1 MMT C) of the total HWP C stock, while

products in SWDS account for 42.7% (149.6 MMT C) of the total HWP C stock.

15

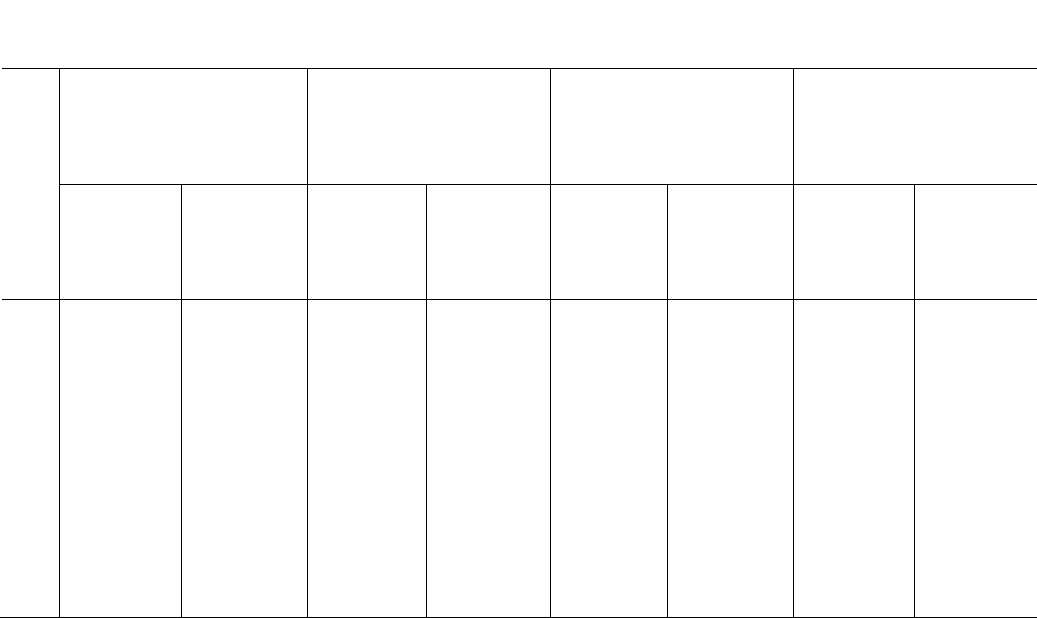

Table 4. Cumulative TPO, HWP C stocks, and emissions from Oregon timber harvests,

1906-2017.

Cumulative TPO MMT C

1906-2017

814.4

Cumulative storage as of 2018

Products-in-use

201.1

End-use products

194.9

Recovered products

6.2

Products in SWDS

149.6

Landfills

138.2

Dumps

11.4

Total HWP stock 350.7

Cumulative emissions as of 2018 MMT C MMT CO

2

e

Emissions with energy capture

155.6

570.4

Emissions without energy capture 308.2 1130.2

Landfills

30.6

112.3

Dumps

130.0

476.5

Recovered products

46.4

170.0

Burning

92.6

339.7

Compost

8.6

31.7

Total emissions

463.8

1700.5

The model output reveals a serrated pattern of annual change to the PIU pool (Figure 3) that

generally reflects the history of timber harvest and TPO (Figure 2). For most years between

1906 and 1992, changes to the PIU pool were positive – more C entered the pool through TPO

and HWP manufacturing than was transferred to SWDS or emissions (Appendix Table 1G). The

time series for this pool can be divided into three basic time periods. Up until 1940 the annual

change to the PIU pool averaged about 1 MMT C/year but then climbed to about 3 MMT C/year

up until 1992, after which it declined to 0.4 MMT C/year until the end of the time series. The

annual change in the PIU pool dropped to below zero during the Great Depression in 1933, near

the end of the Federal timber harvest declines in 1995-2000, and in response to the Great

Recession and housing bust in 2009-2011. During periods of negative annual change, more

carbon transitioned into SWDS than was added to the pool of PIU from harvests, usually as a

result of one or more years of steeply declining timber harvest.

The pool of C in SWDS has continued to grow as HWP from earlier harvest years matriculate

out of PIU and into SWDS (Figure 3 and 4). This movement of HWP C into SWDS, particularly

landfills, has contributed to the overall positive net change in HWP C. The annual change in the

SWDS pool (Figure 3) was positive across the time series and increased in a linear fashion up

until its peak in 1990 at approximately 3.3 MMT C/year. With the decline in timber harvest from

federally owned forests in the 1990s, the annual change in the SWDS pool dropped to

approximately 1.3 MMT C/year by 2002, after which it climbed to about 1.9 MMT C/year by the

16

end of the time series. Consequently, the cumulative amount of C in the PIU pool increased at a

smaller rate after 1992 (Figure 4). The PIU pool increased by approximately 10 MMT C in the 25

years from 1993 to 2018, whereas in the 12 years from 1980 to 1992 it increased by

approximately 30.7 MMT C.

Figure 3. Annual additions to the products-in-use (PIU) and solid waste disposal sites

(SWDS) pools from timber harvested in Oregon 1906-2017. Annual emissions with and

without energy capture (in MMT C/yr) are represented as negative values. “Net”

represents the sum of annual additions and annual emissions.

The amount of annual biogenic emissions from burning fuelwood with energy capture (EEC)

peaked in 1942 at 3.6 MMT C/year (13.2 MMT CO

2

e/year) but then declined in a linear fashion

after 1963 to the end of the time series (emissions are represented as negative values in Figure

3 and 4). Annual biogenic emissions from the decay and burning of discarded HWP without

energy capture (EWOEC) peaked in 1980 at 4.8 MMT C/year (17.7 MMT CO

2

e/year) and have

averaged about 4.3 MMT C/year (15.8 MMT CO

2

e/year) since then. From 1906 to 1975, EEC

was greater than EWOEC but since 1975 EWOEC exceeded EEC (Figure 3). These facts are

likely due to several related factors: 1) the SWDS pool continues to grow as a function of

cumulative TPO and PIU reaching the end of their useful lives (Figure 4); 2) emissions from the

SWDS pool are all EWOEC because the model lacks data on EEC from SWDS; 3) industrial

and residential fuelwood use and the burning of wood waste, as reflected by Oregon’s timber

product ratios, primary product ratios and annual EEC, have generally declined; and 4) markets

17

for mill residue (e.g., sawdust and chips) in Oregon, as reflected in the primary product ratios,

are mainly for pulp and particleboard, rather than biomass energy.

Figure 4. Cumulative stocks of HWP C from timber harvested in Oregon 1906-2017 for

products-in-use (PIU) and solid waste disposal sites (SWDS). Cumulative emissions with

energy capture (EEC) and emissions without energy capture (EWOEC) are represented

as negative values.

The net difference between the annual change in the pool of HWP C and biogenic emissions—

from burning fuelwood for energy capture, and decay and burning of discarded products—was

positive at the start of the time series up until 1914, during three instances between 1944 and

1953, from 1972 to 1975, and again from 1986 to 1990 (Figure 3).

Based on the methods from Harmon (1996) and the BF/CF conversion factors in Table 1, the

cumulative amount of carbon in bark associated with logs harvested from 1906 to 2017 was

approximately 92.21 MMT C (338.15 MMT CO

2

e). To better understand how much bark was

generated at Oregon facilities in a contemporary year we can compare the estimates for bark

from Brandt et al. (2006) with the bark estimate using Harmon’s (1996) method. According to

the former, Oregon’s facilities generated about 1.5 MMT (1.422 million bone dry units (BDU)) of

bark during 2003 while processing timber, 80 percent of which was used as fuel, with nearly all

18

the remaining 20 percent used for decorative bark or soil additives (Brandt et al. 2006). This

amount of bark constitutes a possible lower limit of approximately 2.84 MMT CO

2

e/year in

biogenic emissions, whereas the estimate for 2003 using Harmon’s (1996) method was slightly

higher at 3.24 MMT CO

2

e/year, constituting a possible upper limit. Emissions from bark

utilization for energy production are provided in the Oregon Sawmill Energy Consumption report

(Donahue et al. 2021). Finally, the HWP C model does not treat bark as a wood product and

carbon in bark is accounted for and integrated within the “cut” estimates in the Oregon Forest

Ecosystem Carbon Inventory (Christensen et al. 2019). Therefore, the above annual

approximations for bark associated with harvested wood products would be included in the “cut”

estimates of the Forest Ecosystem Carbon Inventory. To avoid double counting biogenic

emissions from the combustion and decomposition of bark, these bark quantities should not be

added to HWP C unless they are subtracted from the Forest Ecosystem Carbon Inventory.

The computational methods associated with the IPCC production accounting approach requires

carbon to be followed through the duration of a product’s life from harvest through disposal,

applying appropriate ratios and half-lives at each stage (Stockmann et al. 2012). Hence, the

HWP C model accounts for all of the carbon that enters the system as TPO each year and

follows that carbon through its duration as new and recovered PIU, then into the landfills at the

end of product usefulness, and finally as emissions with and without energy recovery. Indeed,

the cumulative amount of all carbon that entered the HWP C model as TPO through 2017

(814.4 MMT C) was accounted for in each of the disposition categories through 2018 (Figure 5;

Appendix 1, table 1H).

19

Figure 5. Carbon Mass Balance showing that the cumulative amount of carbon entering

the HWP pool, as Timber Product Output (TPO) for 1906-2017, is equal to the sum of the

cumulative amounts of carbon in each disposition category through 2018.

Monte Carlo (MC) Simulation Results

After 2,000 iterations, the MC simulation stabilized on values for the mean and the 90%

confidence intervals for the cumulative amount of carbon in the combined HWP pools of PIU

and SWDS (Figure 6). For 2018, the MC estimate for the mean of these two pools combined

was 349.7 MMT C with a lower bound of 291.0 and an upper bound of 410.0 MMT C. The width

of the confidence intervals through the time series reflected the effect of altering parameter

values for amounts of carbon entering the model and being emitted or distributed to different

pools. The precision of parameter estimates for harvest and the ratios for timber and primary

products was modelled as improving over time (Appendix 3, table 3a). Between 1906 and 1920,

the difference between the lower bound relative to the simulated mean averaged about 37%

and the upper bound about 42%. From 2010 to 2017, both the lower and upper bounds

averaged about 17% relative to the mean. The difference between the MC simulation means

and the HWP C model values for the combined pool of PIU and SWDS were less than 1% for

most of the time series, except for the years prior to 1944, when it was slightly larger.

20

Figure 6. Monte Carlo simulated mean and 90% confidence interval for the cumulative

amount of HWP C in PIU and SWDS pools combined.

Confidence intervals were generated separately for the cumulative amount of carbon in the PIU,

SWDS, EEC, and EWOEC pools (Figure 7). The small differences (< 2 MMT C) between the

MC simulated means for these pools in 2018 and the respective estimates from the HWP C

model (Table 5) indicate that the simulation operated as expected given the parameters in

Appendix 3, table 3A. The 2018 MC confidence intervals for EEC, relative to the mean, were the

widest of these four disposition categories at about 24% and 26% for the lower and upper limits,

respectively. Conversely, the width of the 2018 confidence intervals for PIU were the narrowest

at about 18% and 19% of the mean for the lower and upper limits, respectively.

21

Figure 7. Monte Carlo simulation mean and 90% confidence intervals for the cumulative

amount of carbon in products in use, solid waste disposal sites (SWDS), emissions with

energy capture and emissions without energy capture for Oregon’s1906-2017 timber

harvests.

Table 5. Estimates of HWP C (in MMT) for PIU, SWDS, EEC, and EWOEC for the 2018

HWP C model output compared with means and 90% confidence intervals from the MC

simulation.

Disposition Categories

HWP C Model

Output

MC Simulation Mean and

90% Confidence Interval

Products in Use (PIU) 201.1 163.3 < 199.3 < 236.8

Solid Waste Disposal Sites(SWDS) 149.6 122.5 < 150.4 < 179.3

Emissions With Energy Capture (EEC)

155.6

118.7 < 156.0 < 197.3

Emissions Without Energy Capture (EWOEC)

308.2

249.9 < 309.4 < 373.2

22

Stocks and Flux of HWP Carbon by Ownership, 1962-2017

Consistent timber harvest data by ownership class are available for Oregon since1962, which

provides the opportunity to understand how much each ownership has contributed to the pool of

HWP C (Figure 8). From 1962 to 2017, the cumulative TPO for all ownership classes was 514.5

MMT C, from approximately 346.9 bbf Scribner of harvested timber. The volumes and relative

proportions by ownership class vary from year to year and are documented in historic and

recent reports (Andrews and Kutara 2005, Simmons et al. 2019). For example, in 2016,

industrial timberlands accounted for 63.3% of harvest, followed by NIP timber (13.1%), USFS

(9.0%), State (7.3%), BLM (4.7%), Tribal (1.5%) and other public (1.1%). However, the average

for each ownership across the time series shows that timber from industrial ownerships

accounted for 47.2%, USFS 29.5%, BLM 10.2%, NIP 7.7%, State and other public 4.1%, and

Tribal 1.3%.

Figure 8. Cumulative HWP C stock as products-in-use (PIU) and at solid waste disposal

sites (SWDS) by ownership from timber harvested in Oregon, 1962-2017.

Note: The ownership group “Private” includes industrial and non-industrial private forest owners, and “BLM, State, Tribal” includes

BLM, State and other public, and Tribal forest owners (see Appendix 1, Table 1J).

23

Net additions to the HWP stock have generally diminished with declines in total timber harvest

in Oregon from the peaks of the 1970s and ‘80s. This is especially the case for the USFS

ownership that significantly curtailed timber harvest in the 90’s and the consequent decline in

the accumulation in HWP C. Indeed, the annual net increase in HWP C from USFS forests up to

1990 averaged about 2.8 MMT C/year whereas the annual average dropped to -0.2 MMT

C/year after 1990 (Appendix 1, table 1J). Nevertheless, the all-owner total HWP C pool

continued to increase, albeit at a lower rate, with timber harvest from other ownerships. Since

1962, PIU account for about 57% (164.4 MMT C) and SWDS account for about 43% (123.6

MMT C) of the total HWP C pool. About 288.0 MMT C (56%) of the TPO since 1962 remains in

the HWP pools, while 44% (226.5 MMT C or 830.6 MMT CO

2

e) was emitted through burning or

decay.

Net change in HWP C originating from BLM forests increased at an annual average of 0.9 MMT

C/year from 1963 to 1990 but the annual average was slightly negative (-0.04 MMT C)/year)

after 1990 (Figure 9). Net change in HWP C from State and other public forests averaged 0.2

MMT C/year through 1990 and increased to 0.3 MMT C/year after 1990. Net change of HWP C

from Tribal forests increased steadily at an annual average of about 0.1 MMT C/year from 1963

to 2018 (Appendix 1, table 1J). However, the annual change was slightly negative for 2018.

Figure 9. Cumulative HWP C stock as products-in-use (PIU) and at solid waste disposal

sites (SWDS) for the BLM, State and other, and Tribal owners from timber harvested in

Oregon, 1962-2017.

24

Evaluating estimates of HWP C relative to Oregon’s forest ecosystem carbon

Measurements from field plots monitored by the FIA Program indicate that for the 2016

reporting period Oregon’s forests contained approximately 3,239.7 ± 32.8 MMT C in living and

dead trees, understory vegetation, downed wood, roots, forest floor and forest soils across all

ownerships (Christensen et al. 2019; table 4.13a). About 1,118.3 MMT C were in the

aboveground parts of live and dead trees. For the 2017 HWP inventory year (which includes

carbon from timber harvests from 1906 through 2016), the model estimated the amount of

carbon accumulated in the HWP pool was 348.1 MMT C (Table 6), which is equivalent to

approximately 10.7% of the total C in Oregon’s forests and about 31.1% of the aboveground

portion of live and dead trees (1,118.3 MMT C). Finally, the total combined amount of carbon in

Oregon’s forests and HWP in 2016 was approximately 3,587.8 MMT C.

T

able 6. Annual accumulation of HWP C stock, since 2001, in solid waste disposal sites

(SWDS) and products-in-use (PIU) for Oregon timber harvested from 1906-2017.

Inventory

Year

PIU

SWDS

Total HWP C

MMT C

2001

189.5

122.3

311.8

2002

190.0

123.6

313.6

2003

191.2

125.1

316.3

2004

192.6

126.5

319.1

2005

193.9

127.9

321.8

2006

195.1

129.4

324.6

2007

196.2

131.0

327.2

2008

196.4

132.5

328.9

2009

196.1

134.1

330.2

2010

195.1

135.6

330.7

2011

195.0

137.1

332.1

2012

195.7

138.7

334.3

2013

196.4

140.3

336.7

2014

197.9

142.1

339.9

2015

199.1

143.9

343.0

2016

199.7

145.7

345.5

2017

200.5

147.6

348.1

2018

201.1

149.6

350.7

The net v

egetation flux of carbon in Oregon’s forested ecosystems was approximately 30.5

MMT CO

2

e/year (8.3 MMT C/year), after accounting for the transfer of 25.3 MMT CO

2

e/year

(6.9 MMT C/year) to dead wood pools from tree mortality, and 34.8 MMT CO

2

e/year (9.5 MMT

C/year) from trees being cut (Christensen et al. 2019, tables 4.6 and 4.7a). Comparing the FIA

estimates for the amount of carbon cut from forests with estimates for the average TPO is

challenging due to live trees being cut between field plot measurements, with growth equations

being used to estimate tree diameter and height at the midpoint of the measurement interval in

25

order to calculate C at the time of cutting. Moreover, harvesting of timber represented in the FIA

cut estimates could have occurred in any year from 2001 to 2016. The estimate for average

annual TPO output for 2001 to 2016 was approximately 7.0 MMT C/year (25.5. MMT CO

2

e),

approximately 73% of the average cut volume reported in the FIA Oregon Forest Ecosystem

Carbon Report (Christensen et al. 2019).

Considering the model estimates for average HWP emissions with energy capture from burning

fuelwood (EEC = 1.7 MMT CO

2

e/year) and emissions without energy capture (EWOEC = 15.5

MMT CO

2

e/year) for the 2001-2016 time period, the balance of carbon in the pool of HWP (8.4

MMT CO

2

/year) was negative at approximately -8.8 MMT CO

2

e/year. Therefore, the combined

average net change for the pool of carbon in Oregon’s forests and HWP for this time period

(including PIU and SWDS) was approximately 21.7 MMT CO

2

e/year (5.9 MMT C/year).

Discussion

Oregon has a long history of timber harvest and manufacturing of wood products that continue

to retain carbon throughout their use and disposal. Just like the various pools of carbon in forest

ecosystems, the pools of HWP C have dynamic rates of input and output. The analysis

described in this report used the IPCC production approach to generate estimates for the stocks

and flux of carbon in HWP for timber harvested within the State of Oregon from 1906 to 2017. It

also provides estimates for the cumulative emissions of CO

2

e from burning fuelwood for energy

capture and from the decay and burning of discarded wood products. Reliable estimates for

timber harvest among the different ownerships in Oregon are not available prior to 1962,

therefore, this report provides estimates of carbon in HWP for the major forest ownerships that

contributed to HWP C pools from 1962-2017 harvests. The results of the HWP study were

combined with those from the Oregon Forest Ecosystem Carbon Report (Christiansen et al.

2019) to calculate the total stocks and flux of carbon in both forests and HWP. This report

provides the HWP dimension of an overall forest carbon accounting framework for Oregon that

can be used for subsequent HWP C analyses and applied to other regions (e.g., California,

Washington; Christensen et al. 2018) with timber harvest, timber product, primary product and

end-use product data.

Carbon emissions from fossil fuels used in harvest, transportation and manufacturing of HWP

were not estimated and therefore were not deducted from the HWP pools. Although the HWP C

model generates estimates of emissions from burning HWP with energy capture, this study did

not make estimates for substitution of fossil fuel carbon, potentially reducing fossil fuel

emissions in some scenarios (Jones et al. 2010). Furthermore, the HWP C model does not

address carbon or energy associated with substituting HWP for construction materials such as

metal or concrete. While emissions trade-offs from product substitution are outside the scope

and purpose of this report, there are well-developed methods of life cycle analysis (LCA) that

account for all carbon emissions associated with manufactured products and that facilitate the

comparison between wood products and alternative products (Rebitzer et al. 2004, Lippke et al.

2011, CORRIM 2018). The production approach used in this analysis provides information that

could be used to inform an LCA of wood products generated in Oregon.

26

The dynamics in TPO for Oregon generally reflected changes in the economy and changes in

NFS land management through the 1906 to 2017 period. TPO increased from less than 2 MMT

C/year in 1906 to upwards of 13 MMT C/year in 1972, followed by a steep decline upon

implementation of the Northwest Forest Plan. Part of the annual additions to the SWDS C pool

are proportional to additions to the pool of PIU because the model transfers 8% of the carbon in

primary products directly to the discarded pool to account for waste generated during

manufacturing and construction of end-products each year. Wood products with a short half-life

such as crates, pallets, concrete forms, etc., enter the waste stream relatively quickly after

production, which also maintains the waste stream along with the regular demolition of products

with longer durations of use. Consequently, the waste stream of wood products was relatively

smooth during the time series, although it reflects declines following major decreases in harvest.

Many discarded products were disposed of in SWDS rather than burning, which has resulted in

significant quantities of HWP C transferred to these long-term storage pools rather than being

rapidly released into the atmosphere (Skog 2008). The net change in the HWP pool follow the

pattern of annual additions to PIU, slightly lagged, with periods of negative changes following

downturns in the economy and the large decline in federal harvest starting in 1987. The current

negative balances from 2001-2016, reflect the federal harvest decline, followed by the Great

Recession in 2009-2011.

Approximately 25% of the 814 MMT C in the cumulative TPO output since 1906 is currently in

PIU, 18% in SWDS, 19% has been emitted back to the atmosphere from burning fuelwood for

energy capture, and about 38% has been emitted through decomposition or burning without

energy capture. The contribution of carbon to the atmosphere from discarded HWP could be

significantly reduced with further advances in wood waste management. Indeed, end-of-life

management of wood products is perhaps the single most significant variable for the full life

cycle carbon profile of wood products (Sathre and O’Connor 2010).

Estimates of HWP C pools by ownership would be different than reported here if consistent,

reliable harvest information by ownership were available prior to 1962. However, HWP C

storage estimates by ownership for harvests since 1962 show that 59% of the HWP C pool in

2017 originated from private forestlands, 35% from federal forests, and 6% from State, Tribal

and local governments.

Comparing the stocks and flux of carbon in Oregon’s forests and HWP with estimates at the

national level is problematic because the flux of carbon across U.S. forests is based on stock

changes and reported annually, whereas C flux values reported in the Oregon Forest

Ecosystem Carbon Report were based on changes in measurements of individual trees and

averaged over the six years that plot re-measurements were available (EPA 2018; Christiansen

et al., 2019). Nonetheless, Oregon’s forests have been accumulating carbon with an annual

average total forest carbon flux of 30.5 MMT CO

2

e/year (8.3 MMT C/year). This represents

about 5.5% of the average national total forest carbon flux for 2016 of 565.5 MMT CO

2

e/year

(154.2 MMT C/year).

The EPA (2018) estimated that the total stock of HWP C for 2016 (2,591 MMT C) was about

4.7% of the total forest carbon stock for the continental U.S. plus coastal Alaska (55,592 MMT

C). The total stock of HWP C for 2016 in Oregon was 345.5 MMT C (Table 6), which is

equivalent to approximately 10.7% of the estimate for the total C in Oregon’s forests and about

27

13.3% of the national stock of HWP C. For 2017, the total annual input to HWP C from Oregon

was 9.7 MMT CO

2

e/year (Appendix 1, table 1G), which represents about 10.1% of the 2017

national HWP flux of 95.7 MMT CO

2

e/year. These results demonstrate that Oregon contributes

a significant amount to the national pool of HWP C.

Differences between the FIA estimates of cut from Oregon forests and TPO can be attributed to

a combination of differences between forests and HWP accounting methodologies, and

“additional” items in the FIA removals estimate that are not part of TPO. For example, logging

residue generated during timber harvesting, such as needles, branches, tops, and other

removals of non-merchantable material during operations such as pre-commercial thinning, are

included in FIA’s estimate of cut. Of the harvested tree, the stem represents about 67.54%,

while residues (tops, branches, and foliage) represent about 32.46% of total biomass (Ganguly

et al. 2020). In contrast, the HWP C estimates are calculated exclusively from log (wood fiber)

volumes delivered to timber-processing facilities. (i.e., mills). It is also important to note that the

HWP and FIA estimates were developed from very different data sets and methodologies that

prevent direct comparisons. For example, FIA’s estimates of average annual cut from forests

are based on re-measurements of a sample of field inventory plots over a 10-year cycle, while

the HWP estimates are based on annual timber harvest records. Completion of the full re-

measurement cycle for all FIA field plots by 2021 will increase the confidence in the estimates of

the stocks and flux of forest carbon, which should also transfer to comparing and combining

estimates of HWP carbon. There has not been a comprehensive analysis comparing FIA

estimates of removals to timber harvest records in Oregon since FIA began using the current

plot measurement system in 2001.

Conclusions

The pool of carbon in harvested wood products (HWP) is significant in size and should be

considered in decision making associated with carbon monitoring and climate change

adaptation and mitigation (Stockmann et al. 2012). This report provides an empirical accounting

of carbon in timber harvested in Oregon since 1906, with annual estimates of HWP C stocks

and changes in PIU and SWDS. It also includes estimates of C emissions from HWP with and

without energy capture. The information presented here is fundamental to the wood products

dimension of Oregon’s forest carbon accounting framework. It is consistent with the IPCC Tier-3

production accounting approach that was used for the HWP C section in the California Forest

Carbon Inventory (Loeffler et al. 2019, Christensen et al. 2018) and multiple USFS regions and

forests (Stockmann et al. 2012, Anderson et al. 2013, Butler et al. 2014, Loeffler et al. 2014).

The data, modeling framework and results are fundamental to evaluating how the dynamics of

Oregon’s past and current timber harvest levels have influenced the annual growth of the pool

of HWP C and total forest carbon stock levels. The modeling framework does not include

estimates for the emissions associated with timber harvesting, log transportation, HWP

manufacturing, substitution effects of wood products, bioenergy, or leakage.

While this analysis was generated at the state level with details for ownership class back to

1962, it provides an analytical framework that can be used for smaller regions in the state as

28

well.

Published literature with a relatively long time-series of county-level harvest volume data is

available for Oregon (Andrews and Kutara 2005, ODF 2019), including quantitative information

needed for allocating harvest estimates to timber and primary product distributions to reflect the

changes in wood product manufacturing. Clearly, the pool of carbon in HWP generated from

Oregon’s past timber harvests has grown to a large, active pool and, as such, is a significant

consideration when monitoring or developing (forest) carbon management policy. Total forest

carbon integrates the carbon dynamics of forest ecosystems and wood products manufactured

from timber, as well as changing forest management policies and wood product markets.

Periodically updated HWP end-use estimates would allow better HWP C storage and flux

estimates; however, no regional or state-level variations of product end use have been identified

in the literature (Loeffler et al. 2019).

The analysis presented above provides the historical perspective of carbon dynamics in the pool

of HWP C harvested from Oregon’s forests. Given the limitations already stated, the model was

not applied to potential future timber harvest levels. There are several different forest modeling

systems that can be used to predict the outcomes of alternative forest management regimes for

carbon mitigation. The ODF is currently working with partners from the USFS, California,

Washington and British Columbia in evaluating these different forest-modeling systems to

compare their capabilities for generating the carbon outcomes of alternative scenarios for

managing forests and HWPs across this large geographic region. The Carbon Budget Model

(CBM) of the Canadian Forest Sector is currently being tested for forests in Oregon and

California in collaboration with American Forests, ODF, and CalFire, with results expected in

2022. The CBM model will be used to quantify and understand the carbon outcomes of

alternative strategies for managing forests and wood products that integrate new technologies

and policies for recycling and waste disposal.

29

Literature Cited

Anderson, N., Young, J., Stockmann, K., Skog, K., Healey, S., Loeffler, D., Jones, J.G.,

Morrison, J. 2013. Regional and forest-level estimates of carbon stored in harvested

wood products from the United States Forest Service Northern Region, 1906-2010. Gen.

Tech. Rep. RMRS-GTR-311. Fort Collins, CO: USDA, Forest Service, Rocky Mountain

Research Station. 114 p.

Andrews, H.J., Cowlin, R.W. 1940. Forest Resources of the Douglas-fir Region. Miscellaneous

Publication No. 389. Portland, OR: USDA, Forest Service, Pacific Northwest Forest and

Range Experiment Station. 179 p.

Andrews, A., Kutara, K. 2005. Oregon’s timber harvests: 1849–2004. Salem, OR: Oregon

Department of Forestry. 154 p.

Brandt, J.P., Morgan, T.A., Dillon, T., Lettman, G.J., Keegan, C.E., Azuma, D.L. 2006. Oregon’s

forest products industry and timber harvest, 2003. Gen. Tech. Rep. PNW-GTR-681.

Portland, OR: USDA, Forest Service, Pacific Northwest Research Station. 53 p.

Butler, E., Stockmann, K., Anderson, N., Skog, K., Healy, S., Loeffler, D., Jones, J. G.,

Morrison, J., Young, J. 2014. Estimates of carbon stored in harvested wood products

from United States Forest Service Pacific Northwest region, 1909-2012. Unpublished

report. Missoula, MT: USDA, Forest Service, Rocky Mountain Research Station,

Forestry Sciences Laboratory. 28 p.

Christensen, G.A., Gray, A.N., Kuegler, O., Yost, A.C. 2019. Oregon Forest Ecosystem Carbon

Inventory: 2001-2016. Report submitted to Oregon Department of Forestry. Portland,

OR. 347 pp.

Christensen, G.A.; Gray, A.N.; Kuegler, O.; Tase, N.A.; Rosenberg. M; Loeffler, D.;

Anderson, N.; Stockmann, K.; Morgan, T.A. 2018. AB 1504 California Forest Ecosystem

and Harvested Wood Produc

t Carbon Inventory: 2017 Reporting Period. Final Report.

U.S. Forest Service agreement no. 18-CO-11052021-214, 17-CO-11261979-086,

California Department of Forestry and Fire Protection agreement no. 8CA04056 and

8CA03714 and the University of Montana. Sacramento, CA: California Department of

Forestry and Fire Protection and California Board of Forestry and Fire Protection. 539 p.

CORRIM (Consortium for Research on Renewable Industrial Materials) 2018.

[https://corrim.org/].

Cowlin, R.W., Briegleb, P.A., Moravets, F.L. 1942. Forest Resources of the Ponderosa Pine

Region of Washington and Oregon. Miscellaneous Publication No. 490. Portland, OR:

USDA, Forest Service, Pacific Northwest Forest and Range Experiment Station. 113 p.

Donahue, T., Morgan, T.A., Dillon, T. 2021. Oregon Sawmill Energy Consumption and

Associated Emissions, 2017. Report to the Oregon Department of Forestry, Bureau of

Business and Economic Research, Missoula, MT. 26 p.

30

EPA (US Environmental Protection Agency). 2020. Inventory of U.S. greenhouse gas emissions

and sinks: EPA 430-R-20-002. US EPA, Office of Atmospheric Programs, Washington,

DC. https://www.epa.gov/sites/production/files/2020-04/documents/us-ghg-inventory-

2020-main-text.pdf

EPA (US Environmental Protection Agency). 2018. Inventory of U.S. greenhouse gas emissions

and sinks: 1990–2016. EPA 430-R-18-003. US EPA, Office of Atmospheric Programs,

Washington, DC. https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-

emissions-and-sinks-1990-2016.

Gale, C.B., Keegan, C.E., III, Berg, E.C., Daniels, J., Christensen, G.A., Sorenson, C.B.,

Morgan, T.A., Polzin, P. 2012. Oregon’s forest products industry and timber harvest,

2008: industry trends and impacts of the Great Recession through 2010. Gen. Tech.

Rep. PNW-GTR-868. Portland, OR: USDA, Forest Service, Pacific Northwest Research

Station. 55 p.

Galik, C.S., Jackson, R.B. 2009. “Risks to forest carbon offset projects in a changing climate.”

Forest Ecology and Management 2009, 257: 2209-2216.

Galik, C.S., Mobley, M.L., Richter, D.B. 2009. “A virtual “field test” of forest management carbon

offset protocols: the influence of accounting.” Mitigation and Adaptation Strategies for

Global Change 14: 677-690.

Ganguly, I, Pierobon, F., Hall, E.S. 2020 Global warming mitigating role of wood products from

Washington state’s private forests. Forests 11, 194; doi:10.3390/f11020194

Harmon, M.E., Harmon, J.M., Ferrell, W.K., Brooks, D. 1996. Modeling carbon stores in Oregon

and Washington forest products: 1900-1992. Climatic Change 33: 521-550.

Holl, K.D., Brancalion, P.H.S. 2020. Tree planting is not a simple solution. Science Vol. 368,

Issue 6491, pp. 580-581.

Howard, J.O., Hiserote, B.A. 1978. Oregon’s forest products industry: 1976. Resour. Bull. PNW-

RB-79. Portland, OR: USDA, Forest Service, Pacific Northwest Forest and Range

Experiment Station. 102 p.

Howard, J.O. 1984. Oregon’s forest products industry. 1982; Resour. Bull. PNW-RB-118.

Portland, OR: USDA, Forest Service, Pacific Northwest Forest and Range Experiment

Station. 79 p.

Howard, J.O., Ward, F.R. 1988. Oregon’s forest products industry: 1985. Resour. Bull. PNW-

RB-149. Portland, OR: USDA, Forest Service, Pacific Northwest Research Station. 90 p.

Howard, J.O., Ward, F.R. 1991. Oregon’s forest products industry: 1988. Resour. Bull. PNW-

RB-183. Portland, OR: USDA, Forest Service, Pacific Northwest Research Station. 91 p.

Ingerson, A. 2011. “Carbon storage potential of harvested wood: summary and policy

implications.” Mitigation and Adaptation Strategies for Global Change 16:307-323.

31

Jones, J.G., Loeffler, D, Calkin, D., Chung, W. 2010. “Forest residues for thermal energy

compared with disposal by onsite burning: Emissions and energy return.” Biomass and

Bioenergy 34(5):737-746.

Keegan, C.E., III, Morgan, T.A., Blatner, K.A., Daniels, J.M. 2010. “Trends in lumber processing

in the Western United States. Part I: Board foot Scribner volume per cubic foot of

timber.” Forest Products Journal. 60(2): 133–139.

Lippke, B., Oneil, E., Harrison, R., Skog, K., Gustavsson, L., Sathre, R. 2011. “Life cycle

impacts of forest management and wood utilization on carbon mitigation: knowns and

unknowns.” Carbon Management 2(3): 303-333.

Loeffler, D., Anderson, N., Stockmann, K., Morgan, T.A., Tase, N.A. 2019. AB 1504 California

Forest Carbon Stored in Harvested Wood Products: 1952 – 2017. Final Report.

Prepared for: USDA Forest Service and California Department of Forestry and Fire

Protection. University of Montana Bureau of Business and Economic Research, Forest

Industry Research Program, 54 p.

Loeffler, D., Anderson, N., Stockmann, K., Skog, K., Healey, S., Jones, G.J., Morrison, J.,

Young, J. 2014. Estimates of carbon stored in harvested wood products from United

States Forest Service Alaska Region, 1910-2012

[https://www.fs.fed.us/rm/pubs_other/rmrs_2014_loeffler_d002.pdf].

Manock, E.R., Choate, G.A., Gedney, D.R. 1970. Oregon timber industries: wood consumption

and mill characteristics, 1968. Salem, OR: Oregon Department of Forestry. 122 p.

McKeever D.B. 2004. Inventories of woody residues and solid wood waste in the United States,

2002. The Ninth International Conference on Inorganic-Bonded Composite Materials

Conference, October 10-13, 2004. Vancouver, British Columbia, Canada. 12 p.

McKeever, D.B. 2009. Estimated annual timber products consumption in major end uses in the

United States, 1950-2006. GTR-FPL-181, USDA, Forest Service, Forest Products Lab,

49 p.

McKeever, D.B., Howard, J.L. 2011. Solid wood timber products consumption in major end uses

in the United States, 1950-2009: a technical document supporting the Forest Service

2010 RPA assessment. GTR-FPL-GTR-199, USDA, Forest Service, Forest Products

Lab, 39 p.

McKinley, D.C., Ryan, M.G., Birdsey, R.A., Giardina, C.P., Harmon, M.E., Heath, L.S.,

Houghton, R.A., Jackson, R.B., Morrison, J.F., Murray, B.C., Pataki, D.E., Skog, K.E.

2011. “A synthesis of current knowledge on forests and carbon storage in the United

States.” Ecological Applications 21:1902-1924.

Metcalf, M.E. 1965. Timber Resource Statistics for the Pacific Northwest as of January 1, 1963.

Resource Bulletin PNW-RB-9. Portland, Oregon: USDA Forest Service, Pacific

Northwest Forest and Range Experiment Station, 40 p.

32

ODF (Oregon Department of Forestry). 2019. Natural Resources: Timber Harvest Data 1942 –

2018. Data.Oregon.Gov. Available online at:

https://data.oregon.gov/Natural-

Resources/Timber-Harvest-Data-1962-2018/kz4p-3qrv .

Oregon Global Warming Commission (OGWC). 2018. Forest Carbon Accounting Project Report

2018. Salem, OR. 52 p. Available online at:

https://www.oregon.gov/ODF/ForestBenefits/Documents/Forest%20Carbon%20Study/O

GWC-Forest-Carbon-Project-Report-2018.pdf . Last accessed 11/30/2019.

ORS 526.783. 2001. Development of forestry carbon offset accounting system. Available online

at: https://www.oregonlegislature.gov/bills_laws/ors/ors526.html

. Last accessed

11/29/2019.

ORS 468A.250(1)(i). 2007. Mandate of Oregon Global Warming Commission. ORS

468A.250(1)(i). Available online at:

https://www.oregonlegislature.gov/bills_laws/ors/ors468A.html

. Last accessed

11/29/2019.

R Core Team (2020). R: A language and environment for statistical computing. R Foundation for

Statistical Computing, Vienna, Austria. URL https://www.R-project.org/.

RCRA (Resource Conservation and Recovery Act) of 1976 § 42 U.S.C. § 6901 (2011).

Rebitzer, G., Ekvall, T., Frischknecht, R., Hunkeler, D., Norris, G., Rydberg, T., Schmidt, W.P.,

Suh, S., Weidema, B.P., Pennington, D.W. 2004. “Life cycle assessment part 1:

framework, goal and scope definition, inventory analysis, and applications.”

Environmental International 30:701-20.

Ryan, M.G., Harmon, M.E., Birdsey, R.A., Giardina, C.P., Heath, L.S., Houghton, R.A., Jackson,

R.B., McKinley, D.C., Morrison, J.F., Murray, B.C., Pataki, D.E., Skog, K.E. 2010. “

A

s

ynthesis of the science on forests and carbon for U.S. forests.” Issues in Ecology 13: 1-

6

.

Sathre, R., O’Connor J. 2010. A synthesis of research on wood products and greenhouse gas

impacts, 2

nd

Edition. Vancouver, B.C. FPInnovations. 117 p. (Technical Report TR-19R)

Schuldt, J.P., Howard, J.O. 1974. Oregon Forest Industries: Wood Consumption and Mill

Characteristics, 1972. Special Report 427. Corvallis, Oregon: Oregon State University

Extension Service, 113 pp.

Simmons, E.A., Scudder, M.G., Morgan, T.A., Berg, E.C., Christensen, G. A. 2016. Oregon’s

forest products industry and timber harvest 2013 with trends through 2014. Gen. Tech.

Rep. PNW-GTR-942. Portland, OR: USDA, Forest Service, Pacific Northwest Research

Station. 58 p.

Simmons, E.A., Rymniak, L., Morgan, T.A., Marcille, K., Lettman, G., Christensen, G. 2019.

Oregon forest products Industry and timber harvest, 2017: Highlights and summary data

tables. Bureau of Business and Economic Research, Forest Industry Research Program.

http://www.bber.umt.edu/FIR/S_OR.asp

33

Skog, K.E. 2008. Sequestration of carbon in harvested wood products for the United States.

Forest Products Journal 58(6): 56-72.

Smith, J., Heath, L., Skog, K., Birdsey, R. 2006. Methods for calculating forest ecosystem and

harvested carbon with standard estimates for forest types of the United States. Gen.

Tech. Rep. NE-343. Newtown Square, PA: USDA, Forest Service, Northeastern

Research Station. 216 p.

Smith, J.E., Heath, L.S., Woodbury, P.B. 2004. “How to estimate forest carbon for large areas

from inventory data.” Journal of Forestry 102: 25-31.

Spies, T.A., Long, J. W., Charnley, S., Hessburg, P.F., Marcot, B.G., Reeves, G.H., Lesmeister,

D.B., Reilly, M.J., Cerveny, L.K., Stine, P.A., Raphael, M.G. 2019. Twenty‐five years of

the Northwest Forest Plan: what have we learned? Frontiers in Ecology and the

Environment. 35: 1319-. https://doi.org/10.1002/fee.2101

Stockmann, K.D., Anderson, N.M., Skog, K.E., Healey, S.P., Loeffler, D.R., Jones, G., Morrison,

J.F. 2012. Estimates of carbon stored in harvested wood products from the United

States Forest Service Northern region, 1906-2010. Carbon Balance and Management

7(1): 1-16.

USFS (USDA Forest Service). 2019. NFS Carbon Assessments. U.S. Department of

Agriculture, Forest Service. [https://www.fs.fed.us/climatechange/advisor/products.html

]

USURS (Utah State University Remote Sensing)/GIS Laboratory. 2013.

https://www.gis.usu.edu/projects/harvested-wood-products/

Ward, F.R. 1995. Oregon’s forest products industry: 1992. Resour. Bull. PNW-RB-207.