United States

Environmental Protection Agency

Office of Air and Radiation

Washington, DC 20460

EPA-402-R-06-003

March 2006

Technology Reference Guide for

Radiologically Contaminated Surfaces

Technology Reference Guide for

Radiologically Contaminated

Surfaces

EPA-402-R-06-003

April 2006

Project Officer

Ed Feltcorn

U.S. Environmental Protection Agency

Office of Air and Radiation

Office of Radiation and Indoor Air

Radiation Protection Division

This page intentionally left blank.

Technology Reference Guide for

Radiologically Contaminated Surfaces

U.S. Environmental Protection Agency

Office of Air and Radiation

Office of Radiation and Indoor Air

Radiation Protection Division

Center for Radiation Site Cleanup

EnDyna, Inc.

Under Contract No. 4W-2324-WTSZX

i

This page intentionally left blank

ii

Disclaimer

This Technology Guide, developed by USEPA, is meant to be a summary of information available for

technologies demonstrated to be effective for radioactive surface decontamination. Inclusion of

technologies in this Guide should not be viewed as an endorsement of either the technology or the vendor

by USEPA. Similarly, exclusion of any technology should not be viewed as not being endorsed by

USEPA; it merely means that the information related to that technology was not so readily available

during the development of this Guide. Also, the technology-specific performance and cost data presented

in this document are somewhat subjective as they are from a limited number of demonstration projects

and based on professional judgment. In addition, all images used in this document are from public

domain or have been used with permission.

iii

Acknowledgments

This manual was developed by the Radiation Protection Division of EPA’s Office of Radiation and

Indoor Air. Mr. Edward Feltcorn served as the Project Manager. Several individuals provided valuable

input on the content of this Guide throughout its development. Special acknowledgement and

appreciation are extended to Ms. Schatzi Fitz-James and Mr. Ronald Wilhelm of ORIA’s Radiation

Protection Division, Mr. Jami Rodgers of EPA’s Administrative Contract Service Center, Mr. Larry

Boing of Argonne National Laboratory, and Mr. Rick Demmer of Idaho National Laboratory.

Individuals inside and outside EPA who provided peer review are:

U.S. Environmental Protection Agency

Ms. Robin M. Anderson Office of Superfund Remediation and Technology Innovation

Ms. Lindsey Bender Office of Radiation and Indoor Air

Mr. Michael C. Eagle Office of Radiation and Indoor Air

Ms. Schatzi Fitz-James Office of Radiation and Indoor Air

Mr. Roger Goodman Office of Radiation and Indoor Air

Mr. Brian Littleton Office of Radiation and Indoor Air

Mr. Reid J. Rosnick Office of Radiation and Indoor Air

Mr. Stuart Walker Office of Superfund Remediation and Technology Innovation

Mr. Ronald Wilhelm Office of Radiation and Indoor Air

Idaho National Laboratory

Mr. Rick L. Demmer

State of Tennessee

Mr. Robert Storms

Technical support was provided by EnDyna, Inc., under Contract 4W-2324-WTSX, managed by Dr.

Smita Siddhanti and supported by Dr. Ian Tasker.

iv

Preface

This Technology Reference Guide for Radiologically Contaminated Surfaces (Guide) is designed to help

interested parties identify technologies that are potentially useful in removing radiological contaminants

from surfaces as part of a site remediation. The Guide is a snapshot in time and may be updated in the

future. If you have any comments on the document or suggestions for incorporation in future updates,

please contact:

Mr. Edward Feltcorn

U.S. Environmental Protection Agency

Office of Radiation and Indoor Air

Radiation Protection Division

1200 Pennsylvania Avenue, NW (MC 6608J)

Washington, DC 20460-0001

U.S.

Phone: (202) 343-9422

FAX: (202) 343-2306

E-mail: feltcorn[email protected]

.

v

Table Of Contents

List of Acronyms and Abbreviations ...................................................xi

Executive Summary ................................................................xiv

Chapter 1. Introduction

1.1 Purpose ..................................................................... 2

1.2 Regulatory Background ....................................................... 4

1.3 Technical Approach/Document Development ..................................... 5

1.4 Organization and Use of the Guide .............................................. 5

Chapter 2. Chemical Decontamination

2.1 Introduction to Chemical Decontamination ...................................... 11

2.2 Chelation and Organic Acids

2.2.1 Description of Technology ................................................ 14

2.2.2 Target Contaminants ..................................................... 16

2.2.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.5 Operating Characteristics.................................................. 17

2.2.6 Performance ............................................................ 18

2.2.7 Capital and Operating Costs ............................................... 18

2.2.8 Commercial Availability .................................................. 18

2.3 Strong Mineral Acids and Related Materials

2.3.1 Description of Technology ................................................ 19

2.3.2 Target Contaminants ..................................................... 21

2.3.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.3.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.3.5 Operating Characteristics.................................................. 22

2.3.6 Performance ............................................................ 22

2.3.7 Capital and Operating Costs ............................................... 22

2.3.8 Commercial Availability .................................................. 22

2.4 Chemical Foams and Gels

2.4.1 Description of Technology ................................................ 23

2.4.2 Target Contaminants ..................................................... 24

2.4.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.4.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.4.5 Operating Characteristics.................................................. 24

2.4.6 Performance ............................................................ 25

2.4.7 Capital and Operating Costs ............................................... 25

2.4.8 Commercial Availability .................................................. 25

2.5 Oxidizing and Reducing (REDOX) Agents

2.5.1 Description of Technology ................................................ 26

2.5.2 Target Contaminants ..................................................... 27

2.5.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

vi

2.5.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.5.5 Operating Characteristics.................................................. 28

2.5.6 Performance ............................................................ 28

2.5.7 Capital and Operating Costs ............................................... 29

2.5.8 Commercial Availability .................................................. 29

2.6 TechXtract

2.6.1 Description of Technology ................................................ 30

2.6.2 Target Contaminants ..................................................... 31

2.6.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.6.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2.6.5 Operating Characteristics.................................................. 31

2.6.6 Performance ............................................................ 32

2.6.7 Capital and Operating Costs ............................................... 33

2.6.8 Commercial Availability .................................................. 35

Chapter 3. Physical Decontamination

3.1 Introduction to Physical Decontamination ....................................... 36

3.2 Strippable Coatings

3.2.1 Description of Technology ................................................ 38

3.2.2 Target Contaminants ..................................................... 38

3.2.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.2.4 Waste Streams and Waste Management ...................................... 39

3.2.5 Operating Characteristics.................................................. 39

3.2.6 Performance ............................................................ 39

3.2.7 Capital and Operating Costs ............................................... 40

3.2.8 Commercial Availability .................................................. 41

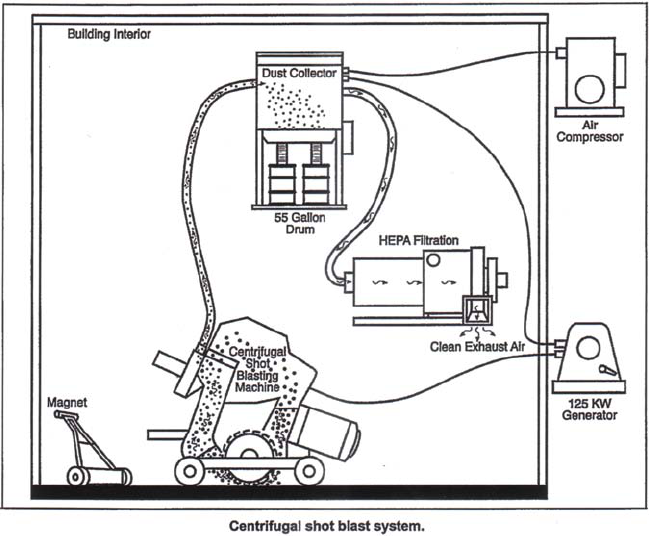

3.3 Centrifugal Shot Blasting

3.3.1 Description of Technology ................................................ 42

3.3.2 Target Contaminants ..................................................... 43

3.3.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.3.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3.3.5 Operating Characteristics.................................................. 43

3.3.6 Performance ............................................................ 44

3.3.7 Capital and Operating Costs ............................................... 46

3.3.8 Commercial Availability .................................................. 48

3.4 Concrete Grinder

3.4.1 Description of Technology ................................................ 49

3.4.2 Target Contaminants ..................................................... 49

3.4.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.4.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.4.5 Operating Characteristics.................................................. 50

3.4.6 Performance ............................................................ 50

3.4.7 Capital and Operating Costs ............................................... 51

3.4.8 Commercial Availability .................................................. 53

vii

3.5 Concrete Shaver

3.5.1 Description of Technology ................................................ 54

3.5.2 Target Contaminants ..................................................... 54

3.5.3 Application Media and Surface Characterization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3.5.4 Waste Stream and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

3.5.5 Operating Characteristics.................................................. 55

3.5.6 Performance ............................................................ 55

3.5.7 Capital and Operating Costs ............................................... 56

3.5.8 Commercial Availability .................................................. 57

3.6 Concrete Spaller

3.6.1 Description of Technology ................................................ 58

3.6.2 Target Contaminants ..................................................... 58

3.6.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.6.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3.6.5 Operating Characteristics.................................................. 59

3.6.6 Performance ............................................................ 59

3.6.7 Capital and Operating Costs ............................................... 60

3.6.8 Commercial Availability .................................................. 62

3.7 Dry Ice Blasting

3.7.1 Description of Technology ................................................ 63

3.7.2 Target Contaminants ..................................................... 64

3.7.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3.7.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

3.7.5 Operating Characteristics.................................................. 65

3.7.6 Performance ............................................................ 65

3.7.7 Capital and Operating Costs ............................................... 65

3.7.8 Commercial Availability .................................................. 66

3.8 Dry Vacuum Cleaning

3.8.1 Description of Technology ................................................ 67

3.8.2 Target Contaminants ..................................................... 67

3.8.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.8.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

3.8.5 Operating Characteristics.................................................. 68

3.8.6 Performance ............................................................ 68

3.8.7 Capital and Operating Costs ............................................... 69

3.8.8 Commercial Availability .................................................. 69

3.9 Electro- Hydraulic Scabbling

3.9.1 Description of Technology ................................................ 70

3.9.2 Target Contaminants ..................................................... 70

3.9.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.9.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

3.9.5 Operating Characteristics.................................................. 71

3.9.6 Performance ............................................................ 71

3.9.7 Capital and Operating Costs ............................................... 71

3.9.8 Commercial Availability .................................................. 72

viii

3.10 En-vac Robotic Wall Scabbler

3.10.1 Description of Technology ............................................... 73

3.10.2 Target Contaminants .................................................... 73

3.10.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

3.10.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

3.10.5 Operating Characteristics................................................. 74

3.10.6 Performance ........................................................... 74

3.10.7 Capital and Operating Costs .............................................. 75

3.10.8 Commercial Availability ................................................. 76

3.11 Grit Blasting

3.11.1 Description of Technology ............................................... 77

3.11.2 Target Contaminants .................................................... 80

3.11.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3.11.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

3.11.5 Operating Characteristics................................................. 81

3.11.6 Performance ........................................................... 81

3.11.7 Capital and Operating Costs .............................................. 82

3.11.8 Commercial Availability ................................................. 83

3.12 High Pressure Water

3.12.1 Description of Technology ............................................... 85

3.12.2 Target Contaminants .................................................... 85

3.12.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.12.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

3.12.5 Operating Characteristics................................................. 86

3.12.6 Performance ........................................................... 86

3.12.7 Capital and Operating Costs .............................................. 87

3.12.8 Commercial Availability ................................................. 88

3.13 Soft Media Blast Cleaning (Sponge Blasting)

3.13.1 Description of Technology ............................................... 91

3.13.2 Target Contaminants .................................................... 91

3.13.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

3.13.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3.13.5 Operating Characteristics................................................. 92

3.13.6 Performance ........................................................... 93

3.13.7 Capital and Operating Costs .............................................. 94

3.13.8 Commercial Availability ................................................. 96

3.14 Steam Vacuum Cleaning

3.14.1 Description of Technology ............................................... 97

3.14.2 Target Contaminants .................................................... 98

3.14.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

3.14.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

3.14.5 Operating Characteristics................................................. 99

3.14.6 Performance .......................................................... 100

3.14.7 Capital and Operating Costs ............................................. 102

3.14.8 Commercial Availability ................................................ 103

ix

3.15 Piston Scabbler

3.15.1 Description of Technology .............................................. 104

3.15.2 Target Contaminants ................................................... 104

3.15.3 Applicable Media and Surface Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3.15.4 Waste Streams and Waste Management Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3.15.5 Operating Characteristics................................................ 105

3.15.6 Performance .......................................................... 105

3.15.7 Capital and Operating Costs ............................................. 107

3.15.8 Commercial Availability ................................................ 109

List Of Exhibits

Exhibit 1-1. Summary of Chemical Decontamination Technologies . . . . . . . . . . . . . . . . . . . . . . . . 7

Exhibit 1-2. Summary of Physical Decontamination Technologies . . . . . . . . . . . . . . . . . . . . . . . . . 8

Exhibit 2-1. EDTA Complex ..................................................... 14

Exhibit 2-2. NPOx Equipment .................................................... 28

Exhibit 2-3. Comparison of TechXtract with Encapsulation and Disposal . . . . . . . . . . . . . . . . . . 33

Exhibit 2-4. Costs for Equipment Rental and Purchase and Rates for Vendor Personnel . . . . . . . 34

Exhibit 2-5. Summary of Production Rates and Unit Costs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Exhibit 3-1. Strippable Coating ................................................... 38

Exhibit 3-2. Centrifugal Shot Blast System .......................................... 42

Exhibit 3-3. Physical Characteristics of Centrifugal Shot Blast Systems . . . . . . . . . . . . . . . . . . . 44

Exhibit 3-4. Performance Results of the Centrifugal Shot Blast Unit . . . . . . . . . . . . . . . . . . . . . . 46

Exhibit 3-5. Conclusions of the Department of Energy Cost Analysis . . . . . . . . . . . . . . . . . . . . . 47

Exhibit 3-6. Summary Cost Comparison Process- Enriched Uranium Material . . . . . . . . . . . . . . 47

Exhibit 3-7. Concrete Grinder .................................................... 49

Exhibit 3-8. Concrete Grinder in Use............................................... 49

Exhibit 3-9. Performance Results for the Concrete Grinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Exhibit 3-10. Department of Energy Cost Comparisons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Exhibit 3-11. Summary of Unit Costs ............................................... 52

Exhibit 3-12. Concrete Shaver ..................................................... 54

Exhibit 3-13. Production Rates and Unit Costs (1997) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Exhibit 3-14. Performance Results of the Concrete Spaller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Exhibit 3-15. Department of Energy Cost Comparisons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Exhibit 3-16. Summary of Unit Costs ............................................... 61

Exhibit 3-17. Typical Pellets ...................................................... 63

Exhibit 3-18. Alpheus Miniblast ................................................... 63

Exhibit 3-19. Pentek Vacuum System ............................................... 68

Exhibit 3-20. En-vac Robotic System................................................ 73

Exhibit 3-21. En-vac on a Wall .................................................... 73

Exhibit 3-22. Chemical Composition of Abrasive Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Exhibit 3-23. Abrasive Characteristics............................................... 79

Exhibit 3-24. Performance of the En-vac and Pentek Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Exhibit 3-25. Summary of Costs and Production Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Exhibit 3-26. Materials Performance and Cost: Nonrecycled Slag vs. Steel Grit . . . . . . . . . . . . . . 83

Exhibit 3-27. Conclusions of the DOE Cost Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Exhibit 3-28. Soft Media Blasting .................................................. 91

Exhibit 3-29. Soft Media Blaster ................................................... 91

Exhibit 3-30. Performance Results of the Soft Media Blast System . . . . . . . . . . . . . . . . . . . . . . . . 94

x

Exhibit 3-31. Conclusions of the Department of Energy Cost Analysis . . . . . . . . . . . . . . . . . . . . . 95

Exhibit 3-32. Summary of Cost Comparison Process - Enriched Uranium Material . . . . . . . . . . . . 95

Exhibit 3-33. The Kelly Decontamination System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Exhibit 3-34. Overall Performance results of the Kelly Decontamination System . . . . . . . . . . . . 101

Exhibit 3-35. Conclusions of the Department of Energy Cost Analysis . . . . . . . . . . . . . . . . . . . . 102

Exhibit 3-36. Pentek Remote Scabbler.............................................. 104

Exhibit 3-37. Remote Scabbler Head ............................................... 104

Exhibit 3-38. Piston Head........................................................ 104

Exhibit 3-39. Performance of the Scabbling Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Exhibit 3-40. Equipment Costs for the Pentek Moose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Exhibit 3-41. Summary of Unit Costs and Production Rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Appendices

Appendix A: References ........................................................ 110

Appendix B: List of Vendors ..................................................... 115

Appendix C: Basic Terms, Types and Units of Radiation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Appendix D: Sources of Information ............................................... 124

Appendix E: Suitability of Surface Decontamination Technologies for Use in an Urban

Environment ....................................................... 125

Appendix F: Emerging Decontamination Technologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Appendix G: “Treatment” Defined by NCP.......................................... 129

Appendix H: Chemical Abstract Service Registry Number (CASRN) for Chemicals Cited . . . . 130

xi

List of Acronyms and Abbreviations

A Ampere

AEC U.S. Atomic Energy Commission

AECL Atomic Energy of Canada Limited

ALARA As low as reasonably achievable

ANL Argonne National Laboratory

ANSI American National Standards Institute

AP Alkaline-Permanganate

ARAR Applicable or Relevant and Appropriate Requirement

ASME American Society of Mechanical Engineers

Bq Becquerel

BRC Below regulatory concern

BRWM Board on Radioactive Waste Management (NAS)

CANDEREM Canadian Decontamination and Remediation Process

CERCLA Comprehensive Environmental Response, Compensation, and Liability Act of 1980 (also

known as Superfund; see also SARA)

CFM Cubic Feet per Minute

CFR Code of Federal Regulations

CITROX Citric acid – oxalic acid process

CLU-IN Hazardous Waste Clean-Up Information (EPA website)

cm centimeter

CMS Corrective Measures Study

CORD Chemical Oxidizing Reducing Decontamination

D&D Decontamination and Demolition (also can refer to Deactivation and Decommissioning

or other combinations of these terms)

DECOHA A fluoroboric acid process

DfD Decontamination for Decommissioning Process (EPRI)

DHS U.S. Department of Homeland Security

DOE U.S. Department of Energy

DPM Disintegrations per Minute

DTPA Diethylenetriaminepentaacetic acid

EC European Commission or European Community

EDDS Ethylenediaminedisuccinic acid

EDTA Ethylenediamine tetra-acetic acid

EHS Electro-hydraulic scabbling

EPA U.S. Environmental Protection Agency

EPRI Electric Power Research Institute

ERDF Environment Restoration Disposal Facility (Hanford)

ERWS En-vac Robotic Wall Scabbler

EU European Union

FEMP Fernald Environmental Management Project

FS Feasibility Study

ft foot

g gram

gal gallon

h hour

HEDTA Hydroxyethylenediaminetriacetic acid

xii

HEPA High efficiency particulate and aerosol (filter)

HPS The Health Physics Society

HPWC High-Pressure Water Cleaning

Hrc Hardness on the Rockwell C Scale

Hz Hertz

ICRP International Commission on Radiological Protection

in inch

INL Idaho National Laboratory

ITSR Innovative Technology Screening Report

kJ kilojoule

kg kilogram

kV kilovolt

kW kilowatts

L Liter

LOMI Low Oxidation State Transition Metal Ion Process

LSDDP Large Scale Demonstration and Deployment Project

LSDP Large Scale Demonstration Project

LTR License Termination Rule

m meter

MDA Minimum Detectable Activity

MEDOC Metal Decontamination by Oxidation with Cerium process

MID Microbially Influenced Degradation

min minutes

mm millimeter

n nano

NAS National Academy of Sciences

NCP National Oil and Hazardous Substances Pollution Contingency Plan

NEA Nuclear Energy Agency

NITROX Nitric acid-permanganate-oxalic acid process (PN Services Inc)

NMSS Nuclear Material Safeguards and Safety

NORM Naturally occurring radioactive material

NP Nitric acid-permanganate process

NRC U.S. Nuclear Regulatory Commission

NUREG Nuclear regulation (NRC)

OECD Organization of Economic Cooperation and Development

OEDPA Oxyethylidenediphosphonic acid

OMB Office of Management and Budget

OPG Oxalic acid-Peroxide-Gluconic acid process

OSC On-Scene Coordinator

OSDF Of-Site Disposal Facility

OSHA Occupational Safety and Health Admistration

p pico

PCB Polychlorinated biphenyl

PH Person Hour

PICS Personal Ice Cooling System

PLF Productivity Loss Factor

PNNL Pacific Northwest National Laboratory

PPE Personal Protective Equipment

PWR Pressurized Water Reactor

psi pounds per square inch

xiii

R&D Research and Development

RCT Radiological Control Technician

RAPIC Remedial Action Program Information Center

REDOX Reduction-Oxidation process

RBMK Reactor Bolshoy Moshchnosty Kanalny (Soviet Nuclear Reactor)

RI Remedial Investigation

RI/FS Remedial Investigation/Feasibility Study

rpm revolutions per minute

s second

SABAR Steel Abrasive Blasting and Recovery System

SARA Superfund Amendments and Reauthorization Act of 1986 (also known as Superfund)

scfm standard cubic feet per minute

SCIRUS A specialized science based search engine (http://www.scirus.com/srsapp/)

SODP Strong Ozone Decontamination Process

SITE Superfund Innovative Technology Evaluation

SRS Savannah River Site (DOE)

TEDE total effective dose equivalent

TENORM technologically enhanced naturally occurring radioactive material

TMS Technology Management System

TUCS Thermally Unstable Complexing Solutions

USACE U.S. Army Corps of Engineers

UV Ultra violet

V Volt

VAC Volts AC

VISITT Vendor Information System for Innovative Treatment Technologies

yr year

xiv

Executive Summary

The U.S. Environmental Protection Agency (EPA), Office of Radiation and Indoor Air (ORIA)

developed this Technology Reference Guide For Radiologically Contaminated Surfaces (Guide) to help

identify surface decontamination technologies that can effectively remove radiological contaminants

from building, structure, and equipment surfaces. These technologies may also be useful in the removal

of non-radiological contaminants, such as hazardous metals, from surfaces. This Guide is designed to

provide easy access to critical information on technologies that are commercially available. This

information is presented in technology profiles that can be used to compare technologies for site-specific

application. The technologies selected for presentation in this Guide include those that could be

considered for response actions.

The technology profiles are categorized under two general classifications:

• Chemical Decontamination Technologies

• Physical Decontamination Technologies

Chemical decontamination technologies include those technologies that involve placing a liquid chemical

or chemical solution in contact with a contaminated surface for a predetermined time and allowing the

chemical properties of the chemicals, the contaminants, and the host matrices to effect the

decontamination. Physical decontamination technologies involve mechanical action, such as abrasion,

scrubbing or grinding of the surface, to remove the contaminant or the contaminant together with the host

surface.

The technology profiles provide a consistent format for presentation of the information obtained from

diverse reference sources. Each technology profile presents the relevant information under eight sections:

1. Description of Technology

2. Target Contaminants

3. Applicable Media and Surface Characteristics

4. Waste Streams and Waste Management Issues

5. Operating Characteristics

6. Performance

7. Capital and Operating Costs

8. Commercial Availability

The Guide is designed to be updated as necessary. A comprehensive review of available information was

performed to identify technologies appropriate for reduction in the level of radioactive contaminants on

building surfaces and equipment. It should be noted, however, that information was not readily available

for all sections of all technology profiles. Reliable cost information was especially difficult to identify in

some cases. However, this Guide summarizes pertinent available information that can be used for

appropriate site response decisions. In addition, an attempt is made to see whether these technologies are

applicable in situations of radioactive dispersion in urban settings.

1

This page intentionally left blank

2

Chapter 1. Introduction

1.1 PURPOSE

This Technology Reference Guide for Radiologically Contaminated Surfaces (Guide) is designed to help

site managers, Remedial Project Managers (RPMs), On-Scene Coordinators (OSCs), their contractors

and others identify technologies that are potentially useful in removing radiological contaminants from

building, structure, and equipment surfaces as part of a site remediation. The Guide is primarily targeted

at sites subject to the Comprehensive Environmental Response, Compensation, and Liability Act of 1980

(CERCLA), as amended by the Superfund Amendments and Reauthorization Act of 1986 (SARA),

although it is hoped that it will be useful for other locations facing similar problems.

To make appropriate site response action decisions, site managers need pertinent technical information to

help guide them. For this reason, the Guide provides basic information on technologies and references to

further information sources. As such, this Guide is decision-focused to help the project manager select an

appropriate technology for surface decontamination that will meet the cleanup criteria.

The Guide assumes that the site manager or other decision maker has had some Superfund experience,

and is generally aware of the hazards associated with radiological contaminants, but does not necessarily

have the expertise of a health physicist. The Guide has a singular focus on decontamination and does not

address other aspects of decommissioning, deactivation or dismantlement. It assumes that a decision has

been made to clean up the structure and that cleanup goals have already been established. It does not

address shielding contamination to prevent exposure. EPA recognizes that site managers fulfill numerous

technical, management, and regulatory responsibilities, all driven by the goal of making expedient, yet

careful, decisions about their actions. In planning and implementing response actions, this document can

be used in the Remedial Investigation/Feasibility Study (RI/FS) or Proposed Plan processes. In addition,

Superfund administrators, EPA site manager counterparts in federal facilities, site managers outside of

EPA, EPA Regional Radiation Program staff, and technology vendors can use the Guide to evaluate

technology options. The Guide is designed to be a resource, not a teaching tool.

The Guide is meant to be an aid to decision making and is not meant to replace other procedures that are

acknowledged as critical to the decision-making process. It may be appropriate to gather information to

support remedy selection and implementation through a small-scale engineering study. Such small-scale

engineering studies are often laboratory based tests that provide critical information on how a proposed

technology will perform under particular real-world conditions. They are relatively low cost and are often

used to provide better data support remedy selection and valuation. Small-scale laboratory tests may be

followed up with advanced or pilot scale tests if more remedy design information is needed.

When properly designed a treatability study should yield information on seven remedy selection criteria:

• Overall protection of human health and the environment,

• Compliance with applicable or relevant and appropriate requirement (ARAR)

• Long-term effectiveness,

• Reduction of toxicity, mobility and volume,

• Short term effectiveness,

• Implementability, and

• Cost.

3

Recognition of the value of this approach will allow the project manager to budget early in the planning

process for decontamination treatability studies, screen for potentially applicable decontamination

technologies, develop remedial alternatives incorporating other considerations such as protective cleanup

levels and waste disposal options, and perform a comparative analysis of alternatives to ultimately select

the final remedial action technology. It is also important to realize that the results of treatability studies

on technologies considered in this Guide are not only applicable to CERCLA remedial actions which

typically address situations where there is a long term threat to human health or the environment, but can

also be applied by On-Scene Coordinators (OSCs) to make selections for CERCLA removal actions,

which are used in situations where there is an immediate threat to human health or to the environment.

Finally, it is appropriate to consider at the outset of the Guide the issue of “treatment.” Radioactive

contamination may be treated by a variety of technologies. The concept of treatment is not solely

dependent on whether contamination is destroyed (though obviously in the case of radioactive material,

destruction as such is not possible), but may also involve removing or stabilizing the contaminant. This

concept of treatment is discussed in the National Oil and Hazardous Substances Pollution Contingency

Plan (NCP) under §300.5, provided in Appendix G of this document. Here, treatment is defined by

whether the technology can or will alter “ ... the composition of a hazardous substance or pollutant or

contaminant through chemical, biological, or physical means so as to reduce toxicity, mobility, or volume

of the contaminated materials being treated.” Furthermore, such technology should generally achieve a

standard of treatment of 90 to 99 percent reduction in concentration or mobility.

From an environmental media standpoint, treatment may include: stabilization (e.g., fixation), thermal

treatment, dehalogenation, soil washing, etc. It typically does not include waste capping in place by itself.

While this latter technology reduces the mobility of the contaminant, for the most part it does not do so

by treating the actual contaminated media.

In a similar manner, treatment of surface contamination includes activities that remove or stabilize the

material on the surface. These may include, for purposes of this guidance, the various washing or

abrasive technologies that remove the contaminant from the surface. Applying shielding material, while a

remediation technology that may facilitate achieving protectiveness or ARAR by limiting direct exposure

and inhibiting resuspension of degraded material, normally would not be considered a treatment

technology. Treatment may also include a stabilization or fixation technology in which an additive

chemically or physically bonds with the contaminant and by immobilizing it prevents the contaminant

from migrating. For nonradioactive contaminants the immobilization of contamination on a surface

followed by removal of the entire structure from a site (“fixation and total removal”) is used at many

residential Superfund sites. This document addresses only decontamination, but notes that fixation and

removal should be explored as a potential option in cases where decontamination is not feasible.

Under CERCLA, the concept of treatment is the same for organic, inorganic or radioactive contaminants.

While some forms of treatment may in fact be capable of destroying or modifying the chemical

composition, other forms of treatment may immobilize the contaminant or may remove the contaminant

from the media, and thus mitigate the former potential exposure pathway. Contaminated materials may be

treated to remove the contaminant from the material. The contaminant and associated treatment residuals

may require further treatment for final waste management.

4

1.2 REGULATORY BACKGROUND

For this document, decontamination is defined as the removal of radiological contamination from the

surfaces of facilities and equipment by a variety of chemical and physical techniques (DOE 1994) with

the objectives of:

• Reducing radiation exposure,

• Enabling reuse of facilities and equipment,

• Reducing the amount of material (equipment, construction and related debris) requiring

expensive disposal,

• Restoring a site or facility to productive use,

• Removing contaminants prior to return to use, further treatment, modifications, protective

storage, or longer-term management and disposal, and

• Reducing the amount of residual radioactivity to be protective of public and worker health and

safety, and the environment.

The hazards associated with radiological contaminants include radiological exposure to personnel from

three potential pathways: 1) direct exposure to external radiation emanating from radioactive

contaminants on surfaces and in equipment; 2) radiation exposure due to inhalation of contaminants that

are already airborne in the facility or are generated during the remediation activities; and 3) radiation

exposure due to ingestion of radioactive contaminants. It should be noted that a technology that addresses

one of these pathways need not necessarily address the others.

Decontamination is usually part of a larger cleanup activity often involving characterization, waste

treatment, dismantlement, demolition, and disposal work. The decontamination activities per se require

two main resources: clearly understood target cleanup levels and technologies to achieve the required

level of cleanup. The technologies themselves, rather than the standards, are the subject of the following

sections of this Guide. Please refer to CERCLA Section. 9621 - Cleanup Standards (42 USC §9621) and

EPA guidance on radiation cleanup standards (EPA 1997).

Standards for radiological decontamination are the subject of much debate and study. Radiological

decontamination may involve comparatively low levels of radioactivity. The situation parallels that of

managing low-activity radioactive wastes where there is a broad spectrum of materials for which a

regulatory framework has evolved in a piecemeal fashion since the late 1940s. This regulatory framework

has often focused on the source rather than on inherent radiological properties or risk. At least 12 federal

statutes apply to some types of, but not all, low-activity wastes. Radiation cleanup standards are set by

the Nuclear Regulatory Commission (NRC), the Department of Energy (DOE), the Environmental

Protection Agency (EPA), and by state regulators (NAS 2003). In addition, a number of other

professional organizations have made recommendations.

Radiological decontamination is also an issue in the consideration of potential terrorist attacks using

radioactive material. On January 3, 2006, the Department of Homeland Security (DHS) published a draft

guidance (for interim use with request for comment), titled Application of Protective Action Guides for

Radiological Dispersal Devices (RDD) and Improvised Nuclear Device (IND) Incidents. The draft is

intended for use by Federal agencies, and as appropriate, State and local governments, emergency

responders, and the general public who may find it useful in planning and responding to an RDD or IND

incidents.

5

1.3 TECHNICAL APPROACH/DOCUMENT DEVELOPMENT

As a basis for selecting technologies to be included in this Guide, a technology, first and foremost,

should be able to remove radioactive contaminants. It could also be useful to remove non-radioactive

contaminants such as organic materials, metals or other inorganic materials. Second, a technology had to

be commercially available from one or more vendors. Third, the technology should have a demonstrated

history in removing contaminants.

It was originally intended that a technology should also be cost effective in its implementation indicating

costs commensurate with decontamination effectiveness. However, technology implementation cost

information and the corresponding details of its application have been extremely difficult to obtain, and

therefore, determining “cost effectiveness” could not be estimated on a reliable basis. Cost data is

included where available.

A comprehensive review of available information was performed to identify technologies appropriate for

reduction in the level of radioactive contaminants on building surfaces and equipment. Details of the

sources and approach are provided in Appendix D.

1.4 ORGANIZATION AND USE OF THE GUIDE

The technology profiles presented in this Guide have been divided into two main classes: chemical and

physical technologies. Chemical decontamination technologies make use of manipulation of the chemical

properties of the contaminants and their host matrices to bring about the decontamination. Physical

decontamination technologies make use of some form of physical or mechanical abrasion of the

contaminant or the host surface material to effect contaminant removal. Section 2.0 reviews the following

five chemical decontamination technologies:

• Chelation and organic acids,

• Strong mineral acids and related materials,

• Chemical foams and gels,

• Oxidizing and reducing agents, and

• TechXtract.

Section 3.0 reviews the following thirteen physical decontamination technologies:

• Strippable coatings,

• Centrifugal shot blasting,

• The concrete grinder,

• The concrete shaver,

• The concrete spaller,

• Dry ice blasting,

• Dry vacuum cleaning,

• Electro-hydraulic scabbling,

• The En-vac robotic wall scabbler,

• Grit blasting,

• High pressure water,

• Soft media blast cleaning (sponge blasting), and

• Steam vacuum cleaning.

6

Each technology profile addresses either a single technology or a single technology type and is divided

into the following eight sections:

• Description of Technology, where a brief, non-exhaustive outline of the technology is presented

• Target Contaminants, where, if appropriate, the specific radionuclide or contaminant host

matrix is described,

• Applicable Media and Surface Characteristics, where the nature (e.g., porosity or chemical

characteristics) and geometry of the surface hosting the contamination are described,

• Waste Streams and Waste Management Issues, where information on the primary and

secondary waste-streams, quantities of waste, containment requirements, and any non-typical

waste treatment, disposal, or other management issues are provided. It should be noted that

certain items, such as used personal protective equipment, are common waste stream elements

for almost all technologies and have not been included in every section except where the vendor

specifically noted the issue.

• Operating Characteristics, where information on worker considerations (e.g., any non-typical

or specialized worker skills or training needed, any non-typical worker safety requirements), any

necessary surface pretreatments, equipment portability or mobility, equipment weight, power

requirements, installation requirements, other complementary technologies usually applied in

conjunction with the subject technology, special regulatory issues or permit requirements, or any

other operating constraints or concerns are presented,

• Performance, where information on documented performance (through treatability studies or

other radiological decontamination projects); performance measures (e.g., setup time,

decontamination factors, removal efficiencies, depth of contamination or surface removal,

number of operating personnel required, ability to clean around encumbrances, ease of

technology equipment decontamination after use); documented applications of NCP criteria;

impacts on performance; and any other technology limitations or needs for future development

are presented,

• Capital and Operating Costs, where information on purchase, rental, operating costs, quotes

from actual projects, comparisons with a baseline technology, and waste management costs are

presented, and

• Commercial Availability, where contact information for technology vendors is presented.

Eight appendices augment the information in the technology profiles:

• Appendix A contains all references cited in the document.

• Appendix B gives the list of contacts/vendors associated with technologies described.

• Appendix C provides basic terms and units of radiation.

• Appendix D gives the additional sources of information for technologies.

• Appendix E provides information related to the applicability of these technologies in situations

of radioactive dispersion in urban settings.

• Appendix F presents capsule summaries of emerging decontamination technologies.

• Appendix G presents the National Contingency Plan definition of the term “treatment.”

• Appendix H provides the Chemical Abstracts Service Reference Number for all chemicals cited

in the text.

A summary of the chemical and physical technologies appears in Exhibit 1-1 and Exhibit 1-2 below.

Each exhibit includes an assessment of the quality of performance data available for the technologies.

This assessment is not exhaustive and is provided for informational purposes only.

7

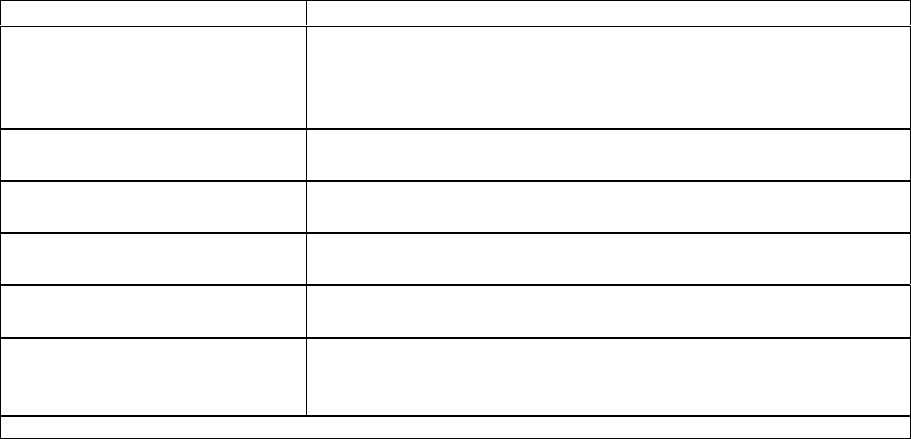

Exhibit 1-1. Chemical Decontamination Technologies

Technology Strengths Limitations Special Considerations Quality of

Performance

Data***

Cost*

Chelation &

Organic Acids

Can be tailored to wide

range of contaminants.

Safer than other chemical

techniques.

Requires considerable

on-hand chemical

knowledge for best

application.

Contaminant

solubilization requires

great care in waste

treament. Danger of

mobilization of the

contaminant.

Poor $10.76/m

2

($1.00/ft )

2

Strong Mineral

Acids & Related

Materials

Can remove very stubborn

deposits. Much operating

experience from industrial

cleaning.

Great care needed

operationally due to

safety considerations.

Can destroy substrate.

Primarily used for metal

corrosion products.

Poor $21.53/m

2

($2.00/ft )

2

Chemical Foams &

Gels

Increased contact time aids

performance. Can reach

remote and hidden areas.

May require repeated

applications to achieve

maximum

effectiveness.

Care must be taken

when flushing since

foams can travel to

areas beyond the reach

of liquids.

Adequate $21.53/m

2

($2.00/ft )

2

Oxidizing &

Reducing Agents

Disrupts matrix where

contaminants hide so small

amounts can be very

effective.

Must be targeted at

appropriate situation.

Will not work if redox

chemistry is not

suitable.

Often used as one step

of a multiple step

process.

Adequate $21.53/m

2

($2.00/ft )

2

and above

TechXtract Highly flexible. Can be

tailored to specific

contaminants.

Best for batch operation

for small objects or for

smaller areas.

Requires optimization

for contaminant and

substrate.

Good $2.15/kg

($0.98/lb)

8

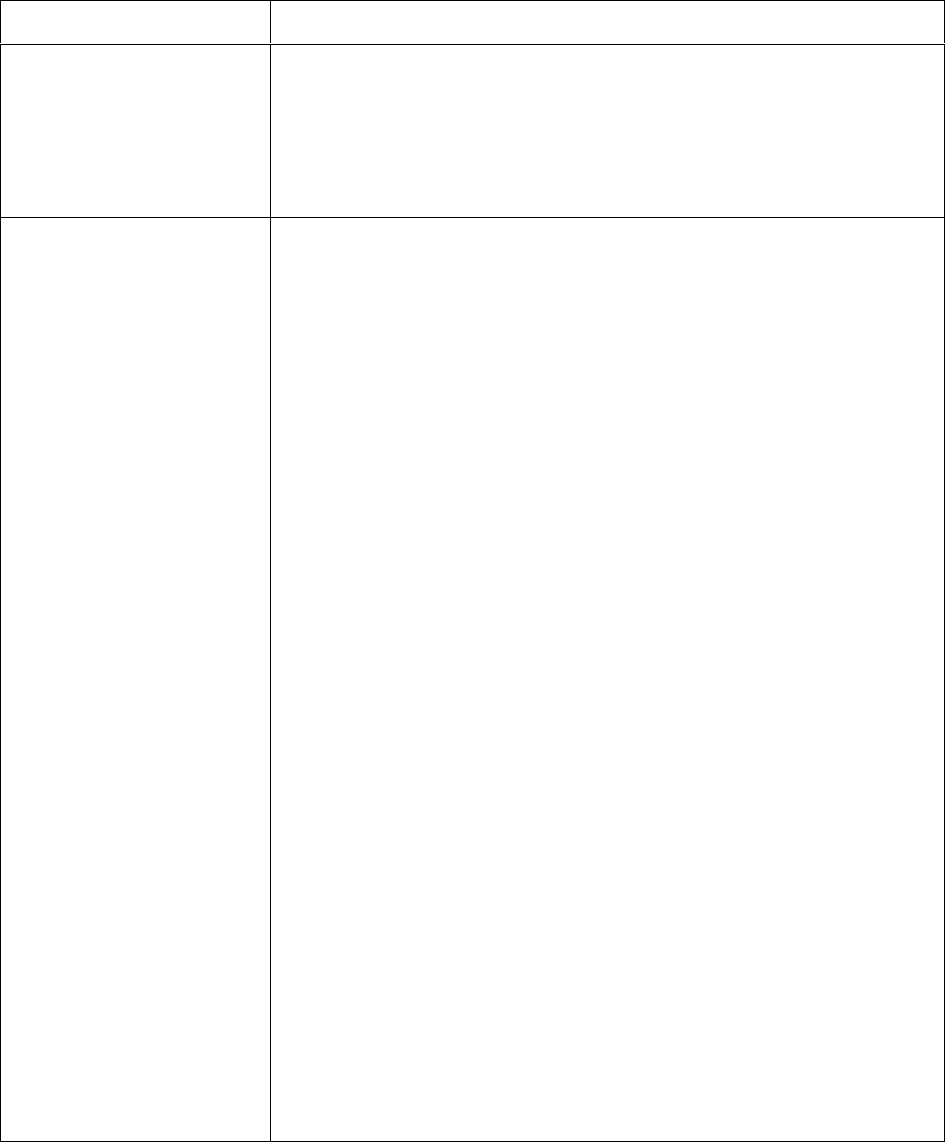

Exhibit 1-2. Physical Decontamination Technologies

Technology Strengths Limitations Special Considerations Quality of

Performance

Data***

Cost*

Strippable Coatings Produce a single solid

waste. No airborne

contamination. No

secondary liquid waste.

The spray gun nozzles

clog. From a cost

perspective, may be

best suited for smaller

decontamination

activities.

Only works for easily

removed (smearable)

contaminants.

Good $52.20/m

2

($4.85/ft )

2

Centrifugal Shot

Blasting

Especially good at

removing paint and light

coatings from concrete

surfaces in open areas away

from wall-floor interfaces.

Escaped shot may pose

a hazard to workers.

May require an air

compressor, systems for

dust collection and air

filtration, a forklift, and

a generator.

Can be limited by large

size, hence unable to

get into corners.

Good $368.66/m

2

($34.25/ft )

2

Concrete Grinder Fast and mobile. Less

vibration.

Small size limits utility. Often best used in

combination with other

technologies.

Good $31.43/m

2

($2.92ft )

2

Concrete Shaver Good for large, flat, open

concrete floors and slabs.

Fast and efficient.

Does not maneuver well

over obstacles. Good

only for concrete floors

and slabs.

Attractive alternative to

hand-held scabblers.

Good $14.21/m

2

($1.32/ft )

2

Concrete Spaller Good for in-depth

contamination. Fast.

Requires predrilling of

holes. Leaves behind a

rough, uneven surface.

Limited commercial

availability.

Good $199.35

/m

2

($18.52/ft )

2

Exhibit 1-2. Physical Decontamination Technologies

Technology Strengths Limitations Special Considerations Quality of

Performance

Data***

Cost*

9

2

Dry Ice Blasting CO gas generates very

little extra waste. Very

good for contamination on

a surface.

Cannot remove

contamination more

deeply embedded in the

surface matrix.

Requires support

systems: air-

compressors, dryers and

filters.

Adequate N/A**

Dry Vacuum

Cleaning

Readily available. Works

well with other physical

decontamination

technologies.

Only good for loose

particles.

Typically used in

conjunction with other

decontamination

technologies

Adequate $21.53/m

2

($2.00/ft )

2

Electro-Hydraulic

Scabbling

Generates less secondary

waste than other

technologies using water.

Very efficient. Removes

deep contamination.

Requires a skilled

operator. Generates

some secondary liquid

waste.

Works best for

horizontal surfaces.

Poor $107.64/m

2

($10.00/ft )

2

and up

En-vac Robotic Wall

Scabbler

Works well on large, open

spaces, including walls and

ceilings. Worker exposure

to contaminants is limited:

remote operation and

integrated vacuum system.

Requires additional

attachments to address

irregular surfaces,

obstacles, and tight

places such as near

wall-ceiling and wall-

floor interfaces.

Remote controlled

aspect allows operation

in areas unsafe for

humans.

Good

$52.74

per hour;

cost

effective at

approx.

139.35 m

2

(1500 ft )

2

Grit Blasting Well-established

technology. Different types

of grit and blasting

equipment are available for

a variety of applications.

Generates large

amounts of dust and

particulates during

operation.

Wide range of grits and

abrasives available for

special situations.

Good Cost based

on En-vac

system.

Exhibit 1-2. Physical Decontamination Technologies

Technology Strengths Limitations Special Considerations Quality of

Performance

Data***

Cost*

10

High Pressure Water High pressure systems are

readily available.

Generates a significant

secondary waste stream.

Can physically destroy

substrate. Best used on

sturdy structures.

Adequate $39.07/m

2

($3.63/ft )

2

Soft Media Blast

Cleaning

(Sponge Blasting)

Removes virtually all of the

contamination from the

surface.

Generates significant

amounts of airborne

contamination. Lower

productivity.

Applicable to surface

decontamination only.

Good $49.51/m

2

($4.60/ft )

2

Steam Vacuum

Cleaning

Easy to use. Washed

surfaces dry quickly. Good

for large flat surfaces.

Not good for irregular

surfaces. Not good for

grease. Poor ergonomic

design.

Not recommended for

surfaces that can be

damaged by steam

temperatures.

Good $146.82/m

2

$13.64/ft )

2

Piston Scabbler Remotely operated and

standard units are available.

Good for open, flat,

concrete floors and slabs.

The units are loud.

Remote units cannot

operate close to wall-

floor interfaces.

Remote controlled

aspect allows operation

in areas unsafe for

humans.

Good $64.58/m

2

($6.00/ft )

2

* Costs may vary widely depending on site specific conditions such as the size of the decontamination project.

** N/A: reliable cost information was not available.

*** The quality of performance is based on professional judgement made on the basis of data collected.

11

Chapter 2. Chemical Decontamination

2.1 INTRODUCTION TO CHEMICAL DECONTAMINATION

Chemical agents are widely used in the nuclear and related industries as decontaminants, primarily to

remove fixed contamination. Chemical decontamination is the most versatile approach to radiological

decontamination since it can draw on the entire discipline of chemistry to find agents able to chemically

transform and remove contamination. Hence, it can, in theory, remove any contaminant. In practice,

however, it is more limited since the same processes that attack the contaminant can also attack the

surface material on which the contaminant resides. Therefore, not all surfaces (e.g., porous material) are

amenable to its use.

Decontamination is essentially a cleaning operation, and chemical decontamination was developed from

the chemical cleaning methods used to maintain large-scale industrial processes. Both cleaning and

decontamination require similar technologies, methods, equipment, and procedures and draw from the

same areas of fundamental chemical knowledge. However, due to concern over the health effects of

radiation from a very small mass of radioactive material, the degree of removal of unwanted material

necessary in decontamination is usually many orders of magnitude greater than in industrial cleaning

since trace amounts of radionuclides present on a surface still render the surface as being

“contaminated.”

Three types of chemical phenomena account for most chemical decontamination techniques: acid or

alkaline dissolution, oxidation/reduction (redox) reactions, and chelation (complexation, sequestration)

reactions. These three are not mutually exclusive and, in fact, are often used together, both

simultaneously and sequentially. This ability to combine techniques adds to the capabilities of chemical

decontamination. However, it also adds complexity to its use and requires that a clear understanding of

the advantages and disadvantages must be obtained.

The advantages of chemical decontamination are:

• In the right situation it can be relatively quick and simple.

• It is similar to classical cleaning in the general industry and can draw on much operational

experience.

• It can be relatively inexpensive where additional equipment is not required.

• With proper selection of chemicals, almost all radionuclides can be removed from contaminated

surfaces.

• Decontamination factors of over 10,000 may be achieved.

• It has the potential to remove contaminants from areas with restrictions to physical access, such

as interior surfaces, crevices, joints, piping, remote internal volumes, hidden parts, complex

geometries.

• It usually involves little or no airborne contamination.

• When properly performed, it can have minimal effects on equipment and surfaces thus allowing

easy reuse.

12

At the same time, the disadvantages of chemical decontamination can be significant:

• Chemical decontamination generates liquid waste streams that require treatment (neutralization,

ion exchange, precipitation, filtration, evaporation) and, in turn, can generate further secondary

waste streams such as spent ion exchangers. Treatment of the secondary waste streams can add

significantly to the cost.

• Safety concerns arise with the use of hazardous materials such as strong acids and oxidizers and

with the production of hazardous byproducts such as hydrogen.

• Chemical decontamination is not usually effective on porous surfaces.

• By mobilizing the contaminant, there is increased risk of downstream recontamination and cross

contamination of equipment, and increased risk of environmental consequences in the event of

accidental releases.

• Sometimes higher temperatures are needed to increase the kinetics of the decontamination.

• Due to the complexity of the systems used, chemical decontamination often requires the

availability of in-depth chemical expertise. This is true both for the decontamination itself and

for ancillary concerns, such as waste stream management.

This last point, that of complexity and the need for scientific expertise, is essential in understanding the

effective use of chemical decontamination. In the case of a simple, small-scale situation such as a minor

liquid spill, a dried spill, or limited particulate contamination, simple chemical decontamination is

usually sufficient. A typical response might be a wash using a detergent solution (for example, half a

kilogram of commercial detergent with half a kilogram of sodium triphosphate in 100 liters of warm

water) followed by a wash using a simple chelator (for example, three kilograms of citric acid or EDTA

(ethylenediamine tetra-acetic acid) in 100 liters of warm water). Though such an approach is excellent

for simple problems, as the complexity of the contamination increases, such as in the decontamination of

nuclear power systems where radiological contaminants are deeply and tenaciously embedded in

corrosion products, so the complexity of the chemical response must increase. Two examples are the

decontamination of: 1) the Reactor Water Clean Up System at Unit 1 of the Browns Ferry Nuclear

Station; and 2) the Indian Point Nuclear Power Plant. At Browns Ferry, decontamination was achieved

using a four-step combination of the Low Oxidation State Transition Metal Ion (LOMI) and alkaline-

permanganate (AP) processes in the order LOMI-LOMI-AP-LOMI (NPJ 2003). At the Indian Point

Nuclear Power Plant, the primary reactor coolant system, the residual heat removal system, and the

chemical and volume control system of Unit 2 were decontaminated using a five-step combination of the

Canadian Decontamination and Remediation Process (CANDEREM) and AP processes in the order

CANDEREM-AP-CANDEREM-AP-CANDEREM (ISOE 1996).

Therefore, although chemical decontamination can be effective, it is affected greatly by the level of

characterization of the problems and level of expertise available to analyze the options for response.

Much of this expertise resides in engineering and service companies that work in the nuclear area, and

the responses they use are the result of in-depth study of the problem.

It should also be realized that a poorly performed chemical decontamination can increase risks. For

example, when contaminants are removed from a surface by chelation, the chelate-contaminant complex

is usually of higher toxicity than the contaminant alone since it usually has a higher bioavailability.

Further, since the contaminant is more mobile when complexed, it is potentially a greater environmental

threat and also poses a risk of cross-contamination of decontamination equipment and other down-stream

recontamination. The decontamination is thus a two-edged sword. The risks can be managed to allow the

technology to perform well, but the appropriate level of thought must be put into it.

13

The technologies presented in the following profiles provide general information on the principal types

of chemical decontamination and should only be considered for further exploration if detailed

characterization and expert assistance is available.

14

2.2 CHELATION AND ORGANIC ACIDS

2.2.1 Description of Technology

Chelation is the binding of an organic chemical to a metal ion in such a way that the metal ion can be

“enveloped” and removed from its insoluble state (e.g., as an oxide deposit), brought into solution, and

hence removed. The organic chemicals, often known as ligands (from a Latin word meaning “to bind”)

and usually referred to as the chelating agents or chelators, tend to have flexible chain structures with

more than one site that can strongly interact with the metal ion. The sites on the chelator have an excess

of negative charge that bind with the positive charge on the metal ion. The technical term for such

ligands is “polydentate” from a Latin root meaning “many teeth” or “many bites.” Thus the chelator has

the ability to grab hold of the metal and pull it away from the surface like a claw taking hold of an object.

In fact, the word “chelation” is derived from a Greek word meaning “crab’s claw.” The term “chelate”

refers to the chemical species where the chelator and the metal ion are bound together. Chelation is also

commonly known as complexation or sequestration.

In the decontamination of nuclear power systems, chelation has the advantage over other chemical

decontamination approaches in that, since the metal ion contaminant is strongly bound up in the chelate

complex, the chance of redeposition or surface binding elsewhere in the system is extremely small. It

should be noted that this advantage also brings some risks: since the contaminant is mobilized by the

formation of the chelate complex, the waste management of the spent decontamination solutions must

include the greatest care so that there are no environmental releases. Mobilized radionuclides can pose

serious health, safety and environmental risks.

There are many potential chelators, each possessing different abilities to bind to different metals. The

most common chelators used in decontamination are:

• Oxalic acid,

• Citric acid,

• Gluconic acid,

• Ethylenediaminetetraacetic acid (EDTA),

• Hydroxyethylenediaminetriacetic acid (HEDTA),

• Ethylenediaminedisuccinic acid (EDDS),

• Oxyethylidenediphosphonic acid (OEDPA), and

• Diethylenetriaminepentaacetic acid (DTPA).

Exhibit 2-1 depicts the chelator EDTA.

All of the chelators listed above are organic acids. From a chemical

perspective, chelators do not have to be organic acids as there are

indeed many excellent neutral organic chelators; but, for

radiological decontamination, having the chelator be an organic acid

provides certain advantages. The acid functionality allows the

chelator to also effect a decontamination similar to that of strong

mineral acids. Since many of the organic acids can be readily

oxidized, they can act as reducing agents and bring about

decontamination by an oxidation-reduction mechanism as well. In

addition, since many chelators are composed of carbon, hydrogen

Exhibit 2-1

15

and oxygen, they can be destroyed by oxidation to produce carbon dioxide and water. This feature can

enable waste treatment options unavailable with other materials.

Chelators can be used on a stand-alone basis:

• Minor spills in radiological facilities are frequently cleaned up with a simple wash of solutions of

EDTA or oxalic acid and using in-house chemical expertise.

• Oxalic acid has been found to be effective for removing rust from iron in nuclear facilities and is

an excellent complexer for niobium and fission products (DOE 1994). During cleaning, however,

secondary deposits of ferric oxalate containing radionuclides may be formed on the

decontaminated surfaces (Ampelogova 1982). Oxalic acid is a basic component of circuit

decontamination technology used for Reactor Bolshoy Moshchnosty Kanalny (RBMK) reactors

(Ampelogova 1982; Nechaev 1998; Sedov 1988).

2

• Oxalic peroxide is used for the simultaneous dissolution of Uranium Dioxide (UO ) and for the

defilming and decontamination of metals (DOE 1994; Ampelogova 1982).

• Citric acid has been used at Capenhurst in the United Kingdom (Boing 1995), and solutions

containing citric acid and Na 2-chromotropic acid have been used in the Kola Nuclear Power

Plant in the Russian Federation (Ampelogova 1982).

However, particularly in the nuclear industry, chelators are usually employed as part of a more complex

or multistage process that combines the chelation phenomena with other approaches, such as strong acid

dissolution or oxidation-reduction. Some examples include:

• The Low Oxidation State Transition Metal Ion (LOMI) decontamination solvent developed by

the Central Electricity Generating Board (UK) and the Electric Power Research Institute (EPRI)

is effective on a wide variety of metal oxides and uses a vanadium (II) reductant with a picolinic

acid chelating agent.

• The CITROX process, a proprietary process of PN Services Inc., uses both citric acid and oxalic

acid as chelating agents.

• The NITROX process, another proprietary process of PN Services Inc., uses cyclic application of

a nitric acid/permanganate (NP) solution followed by oxalic acid as a chelating agent.

• The DfD (Decontamination for Decommissioning) process developed by EPRI uses cyclic

applications of permanganate (an oxidant) and oxalic acid (chelating agent) each in a fluoroboric

acid base solvent.

• The OPG (Oxalic acid-Peroxide-Gluconic acid process) process uses an oxalic acid (chelating

agent), peroxide (oxidizing agent), gluconic acid (chelating agent) solvent, often cycled with

another solvent such as NP, to remove uranium and plutonium oxides.

• The Atomic Energy of Canada Limited (AECL) developed CANDEREM process uses EDTA as

both a chelating agent and reductant together with citric acid as a chelating agent.

• Ammonium citrate has been used successfully after alkaline-permanganate pretreatment and

water rinsing to decontaminate stainless steel and carbon steel (DOE 1994). EDTA can also be

added to this process to keep the iron oxide in solution and inhibit its redeposition (DOE 1994).

One example of its application is at the nuclear submarine prototype reactor in the United

Kingdom (Jones 1995).

• A mixture of oxalic acid, citric acid, and an inhibitor is an effective decontaminant of stainless

steel as the second step after alkaline-permanganate pretreatment (DOE 1994).

• Citric acid is used as a reducing agent, and it is very effective for decontaminating stainless steel

in a two-step process following alkaline-permanganate treatment (DOE 1994).

• Alkaline-permanganate followed by sulfamic acid is effective in removing the contaminated film

from stainless steel piping without causing redeposition of a precipitate (DOE 1994).

16

• Alkaline-permanganate followed by oxalic acid has been successful in removing aged films on

high temperature stainless steel water piping, but it has the disadvantage of causing redeposition

in the form of a tenacious oxalate film on the metal (DOE 1994). This redeposition can be

avoided by using an acidic permanganate solution. Alkaline-permanganate-oxalic acid solutions

have been used in the Russian Federation for circuit decontamination (Ampelogova 1982;

Nechaev 1998).

Chelation can be a very effective process, but it is highly dependent on the availability of expert chemical

knowledge together with in-depth characterization and knowledge of the system to be decontaminated.

2.2.2 Target Contaminants

Chelators can be general (e.g., EDTA which chelates most metals) or specific (cuprizone for copper) in

nature. The state-of-the-art in ligand chemistry is such that chelators can now be designed with extremely

high selectivity, though the cost of the more highly selective chelators is frequently prohibitive for

applications such as decontamination. Chelation is generally used against fixed contamination rather

than smearable contamination, since the latter can usually be removed by simpler means.

2.2.3 Applicable Media and Surface Characteristics

Chelation has been used to decontaminate metal, concrete, wood, and other surfaces, though it is best

used on non-porous surfaces. It is effective on floors, walls, ceilings, piping, and duct work. Since the

technology can be used in spray form, by immersion, or by flushing, it is effective on complex surface

geometries and may be applicable to surfaces or equipment that may have areas accessible only to liquid

chemical reagents.

2.2.4 Waste Streams and Waste Management Issues

The primary waste-stream from use of chelators is the spent chelating solution. The major issue is the

increased mobility of the contaminant in the chelated form and the risks that this poses in the event of

release to the environment. This must be clearly appreciated; in a sense, the chelation process can be

viewed as the very opposite of what a “treatment” is supposed to do - a formerly fixed and immobilized

hazardous material has now been mobilized in a form that has increased toxicity. The situation is

unavoidable, and it can of course be safely managed, but a proper understanding of the phenomena

coupled with relevant engineering knowledge is necessary to safely handle the materials. Solutions of

chelated contaminants can be treated with ion exchange, providing the binding of the metal to the ion

exchange resins is far stronger than it is to the chelator. In such situations the chelator solution is

regenerated and can be reused. More often, the approach is to destroy the chelator, usually by oxidation

with hydrogen peroxide, permanganate, or ultraviolet light, which has the advantage of requiring no

additional chemicals. Since oxidation will produce carbon dioxide, precautions about pressurization

should be taken. When the chelator is destroyed, the previously chelated metals fall out of solution as

precipitates and can be treated by filtration or controlled evaporation to produce a sludge requiring final

treatment prior to disposal.

17

Principal waste management issues include:

• Primary and secondary waste forms (e.g., liquid, solid, gaseous, contaminated surface debris, ion

exchange resin, metal grit),

• Quantities of waste,

• Waste containment requirements, and

• Any non-typical waste treatment, disposal, or other management issues.

2.2.5 Operating Characteristics