Environmental Infection Prevention:

Guidance for Continuously Maintaining a

Safe Patient Care and Survey-Ready Environment

A Guide by Joint Commission Resources

Sponsored by

© 2018 JOINT COMMISSION RESOURCES www.jcrinc.com

Environmental Infection Prevention: Guidance for Continuously Maintaining a Safe Patient Care and Survey-Ready Environment

DISCLAIMER

is guide was supported in part by funding from NexClean. All content in this guide was created and

controlled only by Joint Commission Resources (JCR). You are solely responsible for any decision to use

the guide for assisting your health care organization. It is only a guide, and you have to decide whether

it needs to be tailored to t the practices and settings at your organization. JCR’s provision of this guide,

as funded by NexClean, is on a non-exclusive basis, and is not an endorsement of that company or its

products or services; it is also not a statement that NexClean’s expertise or products or services are superior

to those of other comparable companies. JCR, as a matter of policy, does not endorse products or services.

JCR may make available all the subject matter in this guide to any other party interested in furthering

JCR’s eorts to improve quality and safety.

JOINT COMMISSION RESOURCES MISSION

e mission of Joint Commission Resources (JCR) is to continuously improve the safety and quality of

health care in the United States and in the international community through the provision of education,

publications, consultation, and evaluation services.

© 2018 Joint Commission Resources. All rights reserved. is guide may not be reproduced in any form or

by any means without written permission from JCR. Send requests to make copies of any part of this work

Joint Commission Resources, Inc. (JCR), a not-for-prot aliate of e Joint Commission, has been

designated by e Joint Commission to publish publications and multimedia products. JCR reproduces

and distributes these materials under license from e Joint Commission.

Printed in the USA 5 4 3 2 1

For more information about JCR, please visit http://www.jcrinc.com.

© 2018 JOINT COMMISSION RESOURCES www.jcrinc.com3

Environmental Infection Prevention: Guidance for Continuously Maintaining a Safe Patient Care and Survey-Ready Environment

H

ealth care-associated infections (HAIs) remain a

major cause of patient morbidity and mortality in the

United States, with approximately one out of every 20

hospitalized patients developing an HAI. Although con-

tamination of the patient care environment by microor-

ganisms has long been recognized as a potential con-

tributor to infection transmission, only in recent years has

the significance of environmental contamination been

fully realized. Environmental surfaces such as counter-

tops, sinks, curtains, bedrails, bedside tables, and nurse

call controls can serve as reservoirs for microorganisms

that then may be transmitted to patients or health care

workers when environmental cleaning and disinfection

are inadequate. According to the Centers for Disease

Control and Prevention (CDC), eective and consistent

cleaning and disinfection of the environment in health

care facilities are essential in reducing the incidence of

HAIs.

E.H. Spaulding developed a classification scheme in 1968

to classify items to be disinfected or sterilized based on their

degrees of risk of infection to patients. Hospitals still use

this scheme to guide disinfection and sterilization activ-

ities. The Spaulding system categories are as follows:

1. Critical. Critical items are objects that enter or come

into contact with sterile tissues or the vascular sys-

tem and that have a high risk of transmitting infection.

These include such items as surgical instruments,

cardiac and vascular catheters implants, and objects

placed into the vascular system, such as needles.

Critical patient care items are reprocessed to make

them sterile; that is, all microorganisms, including bac-

terial spores, are killed.

2. Semi-critical. Semi-critical items include those that

come into contact with nonintact skin or mucous mem-

branes, such as respiratory therapy equipment, anes-

thesia equipment, and flexible endoscopes. These

items are processed with high-level disinfection to

eliminate all microorganisms—except for high num-

bers of bacterial spores.

3. Noncritical. Noncritical patient items touch intact skin

only. Because the skin acts as an eective barrier to

most microorganisms, these items pose a low risk

of transmitting infections. Noncritical items include

crutches, blood pressure cus, stethoscopes, and a

variety of other medical accessories as well as non-

medical accessories, such as recreational equipment.

Noncritical items are processed with low- or interme-

diate-level disinfection processes.

See Tool 1 on page 7 for a sample schedule for cleaning

and disinfecting various equipment based on Spaulding

system categories.

This document provides 1) essential elements for eective

environmental infection prevention, and 2) tools for ongo-

ing assessment of environmental infection prevention

practices in health care facilities for noncritical items and

those surfaces that undergo low-level disinfection by unit/

department sta or environmental services sta. Guidance

for high-level disinfection and sterilization can be found in

the High-Level Disinfection and Sterilization Boosterpak

from The Joint Commission, available at https://www.joint-

commission.org/assets/1/6/TJC_HLD_BoosterPak.pdf.

Essential Elements for Environmental

Infection Prevention

While there are various ways to validate the eective-

ness of environmental cleaning and disinfection, all have

demonstrated significant deficiencies in routine cleaning

and disinfection of patient rooms and medical equipment,

with as many as 50% of surfaces still with pathogens pres-

ent after terminal cleaning.

Environmental contamination prevention strategies pri-

marily fall into four categories:

1. Equipment and disinfectant selection

Environmental Infection Prevention:

Guidance for Continuously Maintaining a

Safe Patient Care and Survey-Ready Environment

© 2018 JOINT COMMISSION RESOURCES www.jcrinc.com4

Environmental Infection Prevention: Guidance for Continuously Maintaining a Safe Patient Care and Survey-Ready Environment

2. Preventive maintenance and deep cleaning

3. Adherence to proven methods of cleaning and

disinfection

4. Automated disinfection technologies

Equipment and Disinfectant Selection

Equipment and disinfectant selection is key to eec-

tively preventing infections in the environment. A multi-

disciplinary team rather than individual units or depart-

ments should do equipment and disinfectant selection.

Team members should include infection preventionists,

hospital leaders, housekeeping sta, clinical sta, and

other environment of care professionals. Review man-

ufacturers’ instructions and relevant national guidelines

before purchasing equipment so that you are confident

that the equipment can be properly disinfected and will

not pose a patient or health care worker safety risk. Here

are some considerations when purchasing equipment

and disinfectants:

• Can the equipment be cleaned and disinfected

with a chemical already approved for use in

your organization? Or does the equipment require

introduction of and education on a new chemical?

• Are all surfaces of the equipment able to be

disinfected? For example, are there minimal crevices?

And what about upholstery or wood, which are harder

to disinfect eectively?

• Does the equipment have components that may rust

or deteriorate with repeated cleaning and disinfection?

• For upholstery, can the fabric be disinfected? Maybe

consider vinyl instead of cloth. Does furniture have

open arms to minimize crevices for bed bugs?

• Can flooring surfaces be routinely and easily cleaned

and disinfected? For example, consider a hard

surface instead of carpet.

• When selecting disinfectants, consider the following:

– Equipment compatibility. Try to minimize

the number of disinfectants that are needed.

Preparing a grid listing all equipment and their

disinfectant compatibilities may be helpful in

choosing disinfectants to purchase. Ideally, limit

number of disinfectants stocked to two or three.

(See Tool 2 on page 8 for a sample equipment and

disinfectant compatibility grid.)

– Wet contact time. Try to choose disinfectants

with the shortest wet contact time to aid in sta

compliance.

– Antimicrobial activity. Evaluate what

organisms against which the disinfectant is

eective.

– Choose disinfectants with the lowest possible

risk to sta while still considering the other criteria

listed above.

Preventive Maintenance and Deep

Cleaning

Once equipment has been selected, it must be main-

tained 1) to prevent or reduce the burden of environ-

mental contamination that occurs during use, and 2) to

ensure that the surfaces can be properly cleaned and

disinfected. Routinely assessing surfaces for the follow-

ing can help reduce the burden of contamination:

• Remove tape or other adhesive residue.

• Address surface rust.

• Ensure that Velcro®, if present, is in good condition.

(Minimize Velcro® whenever possible.)

• Ensure that there are no cracks or chips in laminate on

furniture, countertops, and cabinetry.

• Avoid tears or holes in upholstery or mattresses. Patch

any holes or tears with an approved product that can

be cleaned and disinfected (that is, no tape).

• Maintain casters, wheels, tracks, and so forth on

equipment so they function properly and do not build

up debris, dust, or other matter.

• Unclog drains, and routinely remove hard water and

mineral deposits from ice machines, water dispensers,

and any other equipment with water present.

• Ensure that decorative water features, if present, have

correct chemical levels to prevent bacterial growth.

• Properly store equipment and supplies in clean

locations (for example, cabinets, covered linens,

storage rooms, and plastic covers if required by the

organizational policy).

• Routinely clean air vents and change filters per

manufacturers’ instructions.

Cleaning is the removal of foreign material (for exam-

ple, soil, organic material) from objects and is normally

accomplished using water with detergents or enzymatic

products. Thorough cleaning is required before high-

level disinfection and sterilization because inorganic

and organic materials that remain on surfaces interfere

© 2018 JOINT COMMISSION RESOURCES www.jcrinc.com5

Environmental Infection Prevention: Guidance for Continuously Maintaining a Safe Patient Care and Survey-Ready Environment

with the eectiveness of disinfection. While most orga-

nizations have some sort of routine cleaning schedule

for equipment and surfaces, deep cleaning is often not

performed due to operational issues, for example, rooms

being occupied, lack of back-up equipment, or stang.

Developing and maintaining a deep cleaning process

may contribute to more ecient routine cleaning and

will result in more eective disinfection processes. Items

that may be considered for a deep cleaning schedule

include the following:

• Air ducts and grills

• Ice dispensers and storage chests

• Carpeting

• Window blinds and shades

• Privacy curtains

• Clothing washers and dryers

• Mattress and pillow covers

• Beds and bed frames

• Other room furniture and furnishings

Adherence to Proven Methods of Cleaning

and Disinfection

Environmental cleaning interventions can improve the

thoroughness of cleaning and reduce contamination on

surfaces. Interventions have ranged from substituting

one disinfectant for another, such as using hypochlo-

rite for disinfecting rooms of patients with Clostridium

dicile infection, to environmental education programs

with feedback and monitoring. While many studies

have shown a decrease in environmental contamina-

tion, a decrease in HAI rates, and in some cases, an

elimination of an outbreak, it is still unclear which inter-

ventions were most eective because there are very

few well-controlled studies. The organization must

maintain a thorough knowledge of and adherence to

the manufacturers’ instructions for cleaning and disin-

fecting all equipment. Additional studies are needed to

determine optimal frequency of disinfection (terminal,

daily, or more frequent), prioritization of special disin-

fection procedures (high risk units or entire facility), and

the role or added benefit for automated devices such

as ultraviolet light, particularly when standard clean-

ing and disinfection methods have been optimized and

validated.

Strategies to assist with adherence to proven cleaning

and disinfection methods include the following:

• Ensure that sta are educated to their role in

cleaning and disinfection, including

– What cleaner/disinfectant to use on what

equipment

– How to properly apply or use the cleaners/

disinfectants provided by the organization (that is,

wet contact times)

– Who is responsible for disinfecting various

equipment (for example, environmental services,

department/unit sta)

– Frequency in which to disinfect various types

of equipment and surfaces

• Ensure that departments can order only approved

cleaners/disinfectants

Automated Disinfection Technologies

Recent technologies for reducing the burden of patho-

gens on surfaces include antimicrobial surfaces, ultra-

violet light disinfection, deep cleaning/disinfection with

steam or vaporized hydrogen peroxide, and other tech-

nologies. While current studies show reduction in surface

contamination, studies demonstrating corresponding

reduction in HAIs are limited. Organizations may want to

evaluate these technologies for use in addition to exist-

ing proven environmental infection prevention strate-

gies. If using these technologies, organizations should

do the following:

• Ensure that manual cleaning and disinfection are done

prior to use.

• Develop priorities for the use of these technologies

(for example, critical care units, operating rooms,

oncology wards.

• Determine frequency of use of these technologies that

is operationally feasible (for example, at discharge,

end of each day in operating rooms, weekly, monthly.

See Tool 3 on page 9 for an Environmental Infection

Prevention Assessment that you can use to assess your

organization’s practices against Joint Commission stan-

dards for infection prevention and control as they relate

to the environment of care.

© 2018 JOINT COMMISSION RESOURCES www.jcrinc.com6

Environmental Infection Prevention: Guidance for Continuously Maintaining a Safe Patient Care and Survey-Ready Environment

REFERENCES

1. Weber, D, Anderson, D, Rutala, W. “The role of the surface

environment in healthcare-associated infections.” August 2013.

www.co-infectiousdiseases.com Accessed January 2018.

2. Rutala W.A., Weber D.J., and the Healthcare Infection Control

Practices Advisory Committee: Guideline for Disinfection and Ster-

ilization in Healthcare Facilities, 2008. www.cdc.gov/hicpac/pdf/

guidelines/Disinfection_Nov_20 08.pdf. Accessed January 2018.

3. Spaulding E.H.: Chemical disinfection of medical and surgical ma-

terials. In Lawrence C.A., Block S.S. (eds.): Disinfection, Sterilization

and Preservation. Philadelphia: Lea & Febiger, 1968, pp. 517–531.

4. Donskey, C. (2013). Does improving surface cleaning and disin-

fection reduce health care-associated infections? American Jour-

nal of Infection Control 41, S12-S19.

5. Centers for Disease Control and Prevention. Guideline for En-

vironmental Infection Control in Health Care Facilities, 2003.

https://www.cdc.gov/infectioncontrol/pdf/guidelines/environmen-

tal-guidelines.pdf. Accessed March 2018.

© 2018 JOINT COMMISSION RESOURCES www.jcrinc.com7

Environmental Infection Prevention: Guidance for Continuously Maintaining a Safe Patient Care and Survey-Ready Environment

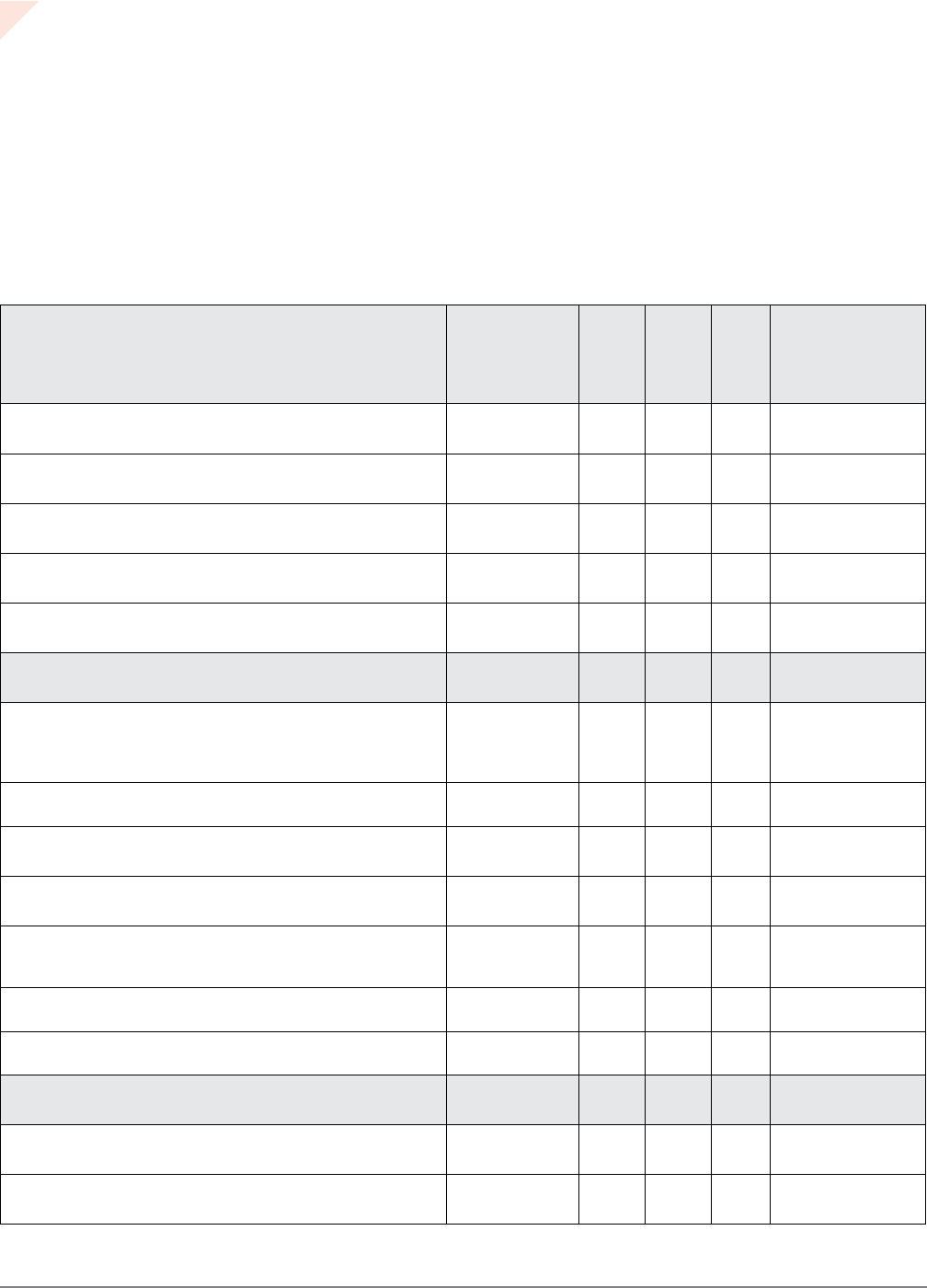

Equipment Spaulding

Classification

Clearning/

Disinfection

Frequency

Person/

Department

responsible

Approved

Disinfectant/

Cleaner

Example: Intravenous pump Non-critical

Daily, when visibly soiled and

between patients

Environmental Services Facility-approved

disinfectant (list

brand name of

disinfectant)

Example: Microwave oven Non-critical

Daily

Food and Nutrition

Services

Facility-approved

bleach disinfectant

Example: Wheelchair Non-critical

Daily and when visibly soiled

Unit sta Facility-approved

disinfectant

Example: Ice and water

dispenser

Non-critical

Daily and when visibly soiled

Food and Nutrition

Services

Facility-approved

bleach disinfectant

Example: Thermometer Non-critical

Between each patient use

Unit sta Facility-approved

disinfectant

Example: Glucometer Non-critical

Between each patient use

Unit sta Facility-approved

disinfectant

Example: Bronchoscope Semi-critical

Between each patient use

Pre-clean at point of use

by unit sta, high-level

disinfection by facility-

determined department

(for example, Sterile

Processing)

Facility- and

manufacturer-

approved high-level

disinfectant or

sterilant

Example: Mattress Non-critical

Between each patient, when

visibly soiled

Environmental Services,

unit sta

Facility-approved

disinfectant

Tool 1. Equipment Cleaning and

Disinfection Schedule

• All equipment and furniture should be routinely evaluated for intact surfaces that can be appropriately disinfected.

• Any damaged surfaces should either be repaired or replaced (for example, patch mattresses; repair chipped laminate; replace equipment

with cracked plastic; remove rust).

• Equipment should be kept in good working order, with preventive maintenance performed on a routine basis and per manufacturers’

instructions.

Department: __________________________________________________________________________________

Date last reviewed/updated: _______________________________________________________________________

© 2018 JOINT COMMISSION RESOURCES www.jcrinc.com8

Environmental Infection Prevention: Guidance for Continuously Maintaining a Safe Patient Care and Survey-Ready Environment

Tool 2. Equipment-Disinfectant

Compatibility Assessment Tool

• Identify the equipment located in your unit/department that you are responsible for disinfecting.

• Determine the disinfectants approved for use in the instructions for use (IFUs) that your organization has approved/provides, and list them

across the top of this tool with the contact time.

• Identify the equipment manufacturer and obtain the manufacturer’s IFUs.

• Place a check mark in the corresponding box under each approved disinfectant for each piece of equipment.

• Once completed, determine the disinfectant that is compatible with the majority of your equipment, with the goal of stocking and using as

few dierent disinfectants as possible (ideally, bleach plus one additional disinfectant) and with the shortest contact time.

Assessment Date: _______________________________________________________________________________

Participants: ___________________________________________________________________________________

Equipment/Surface Manufacturer

Disinfectant #1

(e.g. quaternary

ammonia)

Disinfectant #2

(e.g. quaternary

ammonia)

Disinfectant #3

(e.g. alcohol-free quat)

Bleach

Hydrogen peroxide

Comments

Contact Time (minutes)

3 2 10 1 1

Example: Vitals machine

✔ ✔ ✔

Example: Blood pressure cu

✔ ✔ ✔ ✔ ✔

Example: Intravenous (IV)

pump

✔ ✔ ✔ ✔

Example: Cardiac monitor

✔ ✔

© 2018 JOINT COMMISSION RESOURCES www.jcrinc.com9

Environmental Infection Prevention: Guidance for Continuously Maintaining a Safe Patient Care and Survey-Ready Environment

Tool 3. Environmental Infection Prevention

Assessment Tool

Department: ___________________________________________________________________________________

Assessment Date: _______________________________________________________________________________

Reviewer: _____________________________________________________________________________________

General Environment Joint

Commission

Standard(s)

Yes No N/A Comments/

Actions

Floors and walls are clean and free of spills, dust, stains, tape,

and adhesive residue.

IC.02.02.01

Furnishings (for example, mattresses, chairs, beds, tables) are

free of holes, tears, tape, adhesive residue, stains, and rust.

IC.02.02.01

Curtains, window blinds, vents, sinks and all horizontal surfaces

are clean and dust free.

IC.02.02.01

Ceiling tiles are free of stains, leaks, and holes. IC.02.02.01

All drinks are covered in patient care areas. No food is in patient

care areas.

IC.02.02.01

Supply and Medication Storage Areas

Clean supplies and equipment are clean and free of spills, dust,

stains, tape, and adhesive residue and are kept separate from

dirty supplies and equipment. If required by facility policy, clean

equipment is labeled or bagged as clean.

IC.01.04.01

No patient care supplies are stored underneath sinks or draining

pipes.

IC.02.02.01

Items used to prepare medications are clean. If single patient use,

these are labeled (for example, pill cutters and crushers).

IC.02.02.01

Sterile supplies are stored in a clean, dry enclosed area. IC.02.02.01

Supplies are stored 8 to 10 inches above the oor. All bottom wire

racks in clean supply rooms have a plastic cover or solid bottom

shelf.

IC.02.02.01

No expired supplies (for example, hand sanitizer, soap,

disinfectant wipes, disinfectant solutions)

IC.02.02.01

Corrugated shipping boxes are not stored in clean and sterile

storage locations in clinical areas.

IC.02.02.01

Nourishment Areas

Refrigerators are clean, and freezers are defrosted. IC.02.01.01

Only patient food is stored in refrigerators and freezers found in

patient rooms.

IC.02.01.01

© 2018 JOINT COMMISSION RESOURCES www.jcrinc.com10

Environmental Infection Prevention: Guidance for Continuously Maintaining a Safe Patient Care and Survey-Ready Environment

Nourishment Areas Joint

Commission

Standard(s)

Yes No N/A Comments

Refrigerated patient food brought from home is labeled with the

patient’s name and date made or obtained. No food items greater

than 3 days from the date made or obtained are found.

IC.02.01.01

Refrigerator logs are complete and accurate. IC.02.01.01

Refrigerator temperatures are appropriate. Corrective actions are

documented for temperatures falling out of range.

IC.02.01.01

Microwaves, ice machines and other appliances are clean. IC.02.02.01

Linen and Waste

Clean linen is stored on clean, covered shelves or in enclosed

cabinets separate from dirty linen.

IC.02.02.01

Soiled linen is stored in appropriate plastic bags, in a covered

hamper, or in the soiled utility room.

IC.02.02.01

Sharps containers are not overlled (that is, less than 3/4 full). IC.02.01.01

Trash is disposed of appropriately. Trash in soiled utility rooms is

contained, not overowing or lying on the oor.

IC.02.01.01

Soiled utility room has at least one red receptacle for potentially

infectious medical waste labeled with BIOHAZARD signage.

IC.02.01.01

Soiled reusable instruments that require high-level disinfection

or sterilization are pre-cleaned and stored and transported in a

covered biohazard marked container (for example, endoscopes,

surgical instruments). Soiled instruments are not on countertops

or lying in sinks.

IC.02.02.01

Environmental Services, Hand Hygiene, and Supplies

There is an adequate supply of liquid soap, alcohol-based hand

sanitizer, and paper towels. No expired soap or gel is found.

IC.01.04.01

Dispensers are functional. IC.01.04.01

Sta with direct patient contact do not have articial or long

natural nails.

IC.01.04.01

Sta can verbalize how they know what equipment is clean or

dirty and who is responsible for cleaning and disinfecting it.

IC.02.02.01

Sta can verbalize correct wet contact times for facility-approved

disinfectants and when to use each disinfectant (for example,

bleach versus quaternary ammonia).

IC.02.02.01

Sta can verbalize frequency of cleaning and disinfection of

various pieces of equipment.

IC.02.02.01

Environmental services sta can verbalize correct order if

cleaning and disinfecting a patient room.

IC.02.02.01

Sta use personal protective equipment correctly for cleaning and

disinfection (for example, gloves are not worn in hallways or room

to room).

EC.02.02.01

IC.02.01.01

© 2018 JOINT COMMISSION RESOURCES www.jcrinc.com11

Environmental Infection Prevention: Guidance for Continuously Maintaining a Safe Patient Care and Survey-Ready Environment

Environmental Services, Hand Hygiene, and Supplies Joint

Commission

Standard(s)

Yes No N/A Comments

Environmental services sta can verbalize correct use of cleaning

and disinfection solutions (for example, no double-dipping rags,

frequency of mop head changes).

IC.02.02.01

Environmental services carts are secured. EC.02.02.01

Environmental services closets do not contain patient care

supplies or supplies that may be compromised by moisture

(for example, toilet paper). These items should be stored in a

dedicated clean storage room or cabinet.

IC.02.02.01

If cleaning and disinfection solutions are not ready to use, sta

can verbalize correct dilution per manufacturer’s instructions.

Measuring containers and required personal protective equipment

are available and used.

EC.02.02.01

IC.02.02.01

Secondary containers for cleaners and disinfectants are labeled

per facility policy and in compliance with OSHA requirements. Per

OSHA 29 CFR 1910.1200(f), the employer shall ensure that each

container of hazardous chemicals in the workplace is labeled,

tagged, or marked with the following information:

Identity of the hazardous chemical(s) contained therein; and

Appropriate hazard warnings, or alternatively, words, pictures,

symbols, or combination thereof, which provide at least general

information regarding the hazards of the chemicals, and which,

in conjunction with the other information immediately available to

employees under the hazard communication program, will provide

employees with the specic information regarding the physical

and health hazards of the hazardous chemical.

EC.02.02.01

IC.02.01.01

Deep Cleaning and Preventive Maintenance Joint

Commission

Standard(s)

Yes No N/A Comments

Mattresses, pillows, and covers are in good repair, without holes,

tears, or staining.

Bed frames are clean and in good repair (including side rails,

hinges, casters or wheels, and bases).

Carpet, if present, is clean, without stains, and on a routine

extraction schedule.

Ice machines and storage bins are clean and maintained.

Privacy curtains are visibly clean and on a routine cleaning/

laundering schedule.