www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

1. MECHANICAL DEFECTS

1.1 Stitching

Stitching is a defect which can be detectable both visually and acoustically. Silver dots can be seen

in the reection of the record, forming clusters and chains. This generally happens when records are

incorrectly removed from the mould (usually occurring when both sides of the mould release at the

same time). The visual defect is acceptable, unless it also aects the audio properties.

1.2 Non-fills

These are visible silver lines in the reection on the record, known as nests of ne depressions. This

results in the grooves of the record being incorrectly copied and the compound material is missing

on the upper edge of the groove. The issue usually occurs at the edge of the record, and in lead-in

and lead-out areas. They are not always audible.

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

Technical Conditions & Disclaimers

Continue to the next page

WHEN DEFECT IS UNACCEPTABLE

An audible defect is not acceptable.

WHEN DEFECT IS UNACCEPTABLE

A critical defect that is almost always

unacceptable if audible.

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

1.3 Scratches (damaged stamper)

A visible scratch on the record that appears on each record in the same place. This occurs when the

stamper has been damaged during the pressing process.

1.4 Scratches (damaged by handling)

There are visible clusters of parallel grooves on the record surface. The principal cause is from rough

handling.

OTHER RISKS: Surface scratches are largely inuenced by the inner sleeve used, which can impact and

cause damage to the record.

RECOMMENDATION: In terms of protecting the record from damage, the most eective option the

poly-lined sleeves, after this we recommend a microtene or PE sleeve, then a PREMIUM printed sleeve

which uses a laminate on the inside.

The lowest protection of records is oered by standard white/black inner sleeves which can cause

hairline scratches on the mirror area and in the grooves. In addition, these sleeves can release ne

paper particles from the edges.

Next is printed paper sleeves and card discobags without the inner lamination, which can also cause

ne scratches on the mirrored area and in the grooves, due to releasing paper residues from the

edges. Although these defects have no inuence on the sound quality, they are undesirable.

The least suitable material are card stocks and art paper that can cause scratches to vinyl records.

These are especially problematic if the inside of the sleeve is also printed.

WHEN DEFECT IS UNACCEPTABLE

All scratches that aect the audio quality.

Scratches that exceed 20mm long and 0.5mm

wide are unacceptable.

WHEN DEFECT IS ACCEPTABLE

The defect must not aect the audio quality.

Hairline and ne scratches must only occur

outside of the audio area.

The length of the scratches must not exceed

20mm and the thickness must not exceed

0.5mm.

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

WHEN DEFECT IS UNACCEPTABLE

All scratches that aect the audio quality.

Scratches that exceed 20mm long and 0.5mm

wide are unacceptable.

WHEN DEFECT IS ACCEPTABLE

The defect must not aect the audio quality.

Hairline and ne scratches only on the vinyl

surface, especially on the non-groove/mirror

area. The length of the scratches must not

exceed 20mm and the thickness must not

exceed 0.5mm.

WHEN DEFECT IS UNACCEPTABLE

All defects in this case are unacceptable.

Continue to the next page

1.5 Cold Centre

Due to insucient heating, the centre of the record is deformed and becomes too thick, and or

indented the incorrect way. The centre hole will then be too small.

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

1.6 Dirt and other residues

The record contains a particle that creates a protrusion or there is paper particles visible on the

surface. This defect is caused by processing of contaminated pressing material (such as burnt pieces

of paper).

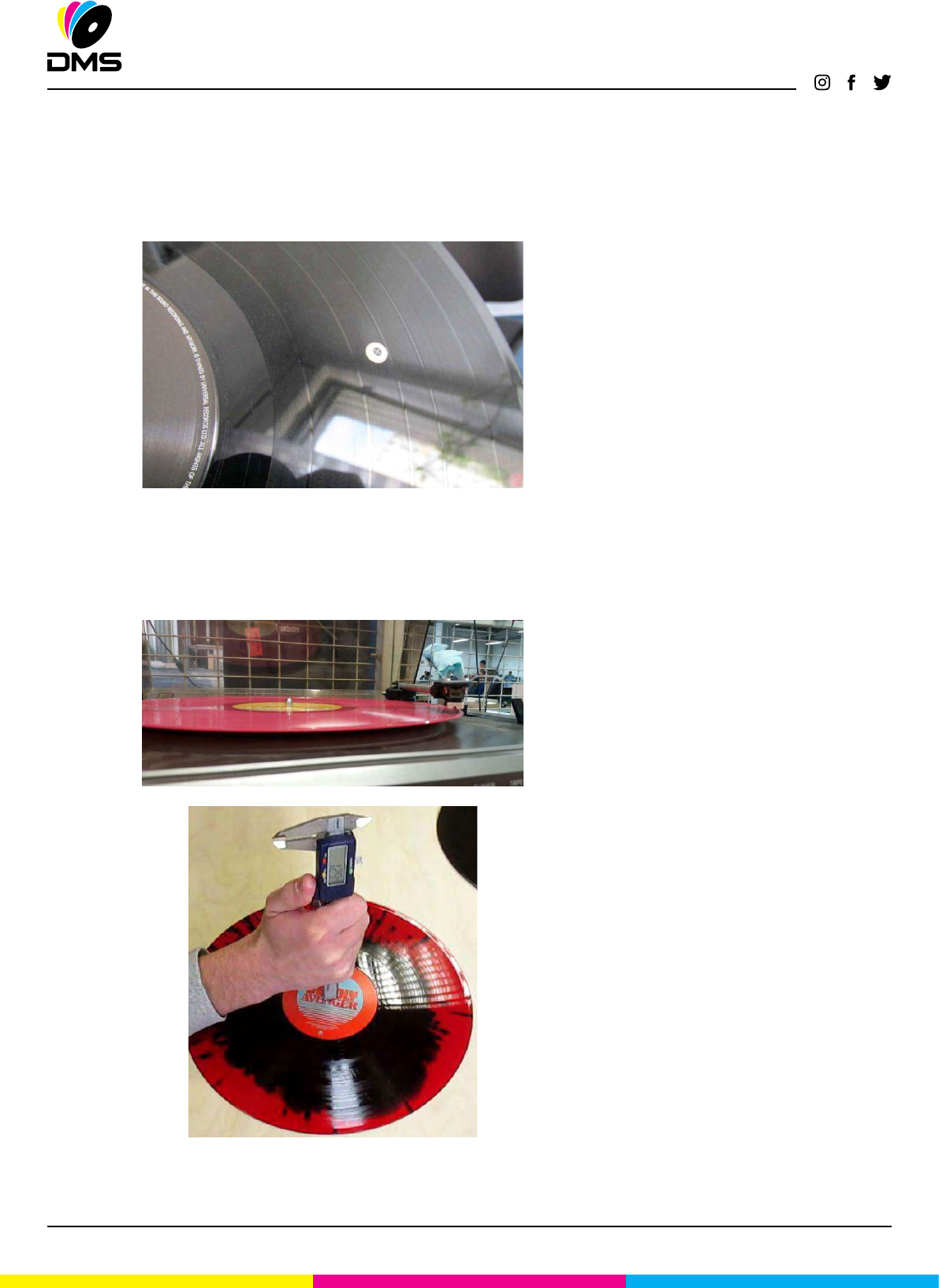

1.7 Warped records

The root cause of warping is high inner tension during the maturing process or long-term unsuitable

storage.

WHEN DEFECT IS UNACCEPTABLE

All defects in this case are unacceptable.

WARPING STANDARDS

There are two ways of measuring

warping:

1. With a special device similar to a

record player, that has a laser deviation

gauge which measures the height

dierence between minimum and

maximum values during rotation from

lead-in to lead-out. Both dish warping

and propeller/saddle warpage can be

measured with this device.

2. With a manual device similar to a

ruler. The record has to lie on an even

surface and the distance between the

surface and the record is measured in

the centre hole. Only dish warping can

be measured with this method.

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

1.8 Stains and smudges on records

The vinyl material (puck) contains extraneous ingredients, most often black material. We distinguish

two types of stains/spots – visible dotted stains, mainly black and smudges.

WHEN DEFECT IS UNACCEPTABLE

The area of the spots exceeds 6 mm of the total

area for compact spots and 350 mm of the total

area for not compact spots (smudges).

WHEN DEFECT IS ACCEPTABLE

The accepted area of these spots shall not

exceed 6 mm of the total area for compact,

homogeneous stains whose colour is distinctly

dierent from the rest of the record and 350

mm of the total area for spots (smudges) that

are not compact, but more like a dierent shade

of the same colour as the rest of the record.

The reference area is the entire record area

including the label. The coverage of stains is

calculated as a whole. The total area of all stains

on one side may not exceed the values stated

above.

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

1.9 Vinyl colour

The colour does not correspond with the vinyl colour chart.

METALLIC COLOURS - These colours are composed of pigments and metallic particles. The mixing

of these elements can cause dierent shades or ‘waves’ within one record which can be particularly

noticeable in the non-audio areas. This is a characteristic of the colour and cannot be subject to claim.

1.10 Blisters

Blisters usually occur during the process of adding splatters to the puck. When there is insucient

melting of the dierent materials during pressing, bubbles can occur on the vinyl surface, causing an

acoustic issue.

WHEN DEFECT IS ACCEPTABLE

The maximum colour deviation can be judged as

being within two Pantone colour grades.

WHEN DEFECT IS UNACCEPTABLE

A colour deviation of more than two Pantone

colour grades.

WHEN DEFECT IS UNACCEPTABLE

The defect is unacceptable in any

case when the blister exceeds the

vinyl surface.

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

2. LABEL DEFECTS

2.1 Label cut

The label design is o centre by more than 2mm and or cropped dierently to the proofs.

2.2 Colour change of label

All labels are subject to a drying process at high temperatures in order to remove excess moisture

which is required to prevent the labels bubbling during pressing. Due to the drying process the labels

may change colour. This eect is more visible on areas of white, light colours and Pantone colours.

Below are some examples (please note, not all eventualities are shown here).

WHEN DEFECT IS UNACCEPTABLE

The cut is o centre by more than 2mm and or

the label text is cut o (providing the text is not

within the recommended safety areas)

WHEN DEFECT IS ACCEPTABLE

The cut is o centre by 2mm or less and without

cutting the label text.

Colour before drying and pressing Colour after drying and pressing

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

2.3 Wrong labels

The labels do not match the label proofs. Dierent labels have been used or the labels of each side

have been switched.

2.4 Double labels

The label is blown throughout the entire surface and is doubled.

WHEN DEFECT IS UNACCEPTABLE

A critical defect that is always

unacceptable.

WHEN DEFECT IS UNACCEPTABLE

The defect is unacceptable in any

case.

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

2.5 Cracked label

The labels can crack during the pressing process and label parts are shifted.

RISKS TO BE AWARE OF: Cracked labels occur mostly on multi-coloured records with eects. The

unpredictable paper tension during pressing can cause cracks or label folding issues, due to the use

of dierent compound materials which can have varying properties.

2.6 Blisters on labels - Picture Discs

The picture disc foil incorrectly adheres to the label causing a blister.

WHEN DEFECT IS UNACCEPTABLE

The area of all blisters is greater than 100mm or

blisters are located outside of the centre.

WHEN DEFECT IS ACCEPTABLE

The total area of all blisters does not exceed

100mm and or the blisters are in the centre of

the label.

Continue to the next page

WHEN DEFECT IS ACCEPTABLE

Hairline splits, where the text is still legible.

WHEN DEFECT IS UNACCEPTABLE

The vinyl material is visible through the label

split. The label text is illegible.

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

2.7 Blisters on labels

Insuciently dried ink can bubble on the hot stamper surface during pressing, which then causes the

labels to stick to the stamper surface. When opening the pressing machine, the printed surface can

be torn o or the paper can split in layers resulting in blisters.

2.8 Torn label at the centre hole

The label is torn by the centre pin when it is inserted into the press.

WHEN DEFECT IS UNACCEPTABLE

The area of all blisters is greater than 100mm2

WHEN DEFECT IS ACCEPTABLE

The area of all blisters is up to 100mm2

WHEN DEFECT IS UNACCEPTABLE

The top layer of paper is torn o and a white area

is created.

WHEN DEFECT IS ACCEPTABLE

The tear may only be of a hairline nature. The top

layer of the paper must not be torn o. The tear

size is up to 5mm at the centre hole.

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

2.9 Ripped print/surface on labels

Insuciently dried ink bubbles on the hot stamper surface during pressings and sticks to the stamper

surface. When opening the pressing machine, the printed surface can be torn o.

2.10 Label spots

Stains can occur on splattered records when some of the material gets on the label during the

pressing process. These are supposed to be rejected only if the information content is damaged or

the sum of the areas of the stain exceeds 1.5% of the label area.

1.5% of the label area = 100mm which can be imagined as a 10mm x 10mm square.

Continue to the next page

WHEN DEFECT IS UNACCEPTABLE

The tear in the edge of the label is larger than

3cm.

WHEN DEFECT IS ACCEPTABLE

The tear along the edge of the label may be no

more than 3cm in circumferential length. The

defect must not cause the text to be illegible or

missing.

WHEN DEFECT IS UNACCEPTABLE

The sum of the areas of all spots is greater than

100mm or the spots prevent the text from

being legible.

WHEN DEFECT IS ACCEPTABLE

The sum of the areas of all spots must not exceed

100mm . Texts must be legible.

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

2.11 Scratches on labels

The defect is caused by rough handling. The label is rubbed against the centre pin when removing

the record from the press.

2.12 Contamination of labels

Contamination can occur during handling or whilst packing the record to sleeves.

WHEN DEFECT IS UNACCEPTABLE

The top layer of the paper is damaged.

WHEN DEFECT IS ACCEPTABLE

The mark on the label surface has not damaged

the top layer of the paper. The total number of

aected labels does not exceed 10% of the run.

WHEN DEFECT IS ACCEPTABLE

Contamination is acceptable if the total

area is not more than 100mm and is

contained to the centre of the label.

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

3. COLOUR EFFECTS

EFFECT #1 - SPECKLES/SPLATTERS

The base colour can be either solid or transparent, however for best results the splatters should

generally be chosen from the solid range of colours. You can use up to 3 splatter colours.

If using black or dark solid colours as the ase, these can absorb the splatter colours. For best results

we recommend light colours, ideally transparent as the base, with solid and or darker colours than

used on the base.

Please note that speckles can appear on top of the label artwork, obscuring it slightly, the tolerance

is 100mm2 total surface area aected, providing text is still legible.

EFFECT #2 - HALF / HALF

This eect can be made from a combination of both transparent and solid colours. Great for split

releases. The best combinations are two contrasting opaque, or two contrasting transparent colours.

However, most combinations should work well, so please discuss with your account manager.

Please be aware, on rare occasions there can be a sound quality disparity as playback crosses one

colour to the other.

EFFECT #3 - COLOUR IN COLOUR

Another two colour eect. This option produces a totally random eect on each side of the record.

Please be aware that we cannot guarantee that both colours will be visible on both sides of the

record. Also note that darker colours can dominate lighter colours, so we recommend making the

darker one the small central one. It is best to use a transparent colour for the outside and a solid

colour for the inside.

If you opt for two solid colours, the results are not guaranteed and could end up looking like side A/B

eect.

This eect is not available for 7” vinyl, unless you specically use a smaller centre label, otherwise the

eect can be hidden under the standard sized labels.

EFFECT #4 - SIDE A/ SIDE B

Also known as swirl, merge or mix. Along with splatters, this is by far the most popular eect and

gives a totally unique appearance for every single pressing. We generally advise that colours are

chosen from the solid range, but some transparent colours do work too!

If using this eect for 7” vinyl, we would recommend using smaller centre labels to ensure the eect

is as visible as possible.

EFFECT #5 - TRI-COLOUR (120° Segments or stripes)

This type of record can be made from any combination of both solid and transparent colours. The

three colours can be positioned as 3 x 120° (approx.) segments around the vinyl or as stripes.

As with a Half & Half eect, there can on rare occasions be a sound quality disparity as playback

crosses one colour to the other.

EFFECT #6 - QUAD

This eect uses two or three colours to create four segments around the vinyl. This type of record can

be made from any combination of both solid and transparent colours. If choosing 3 colours, please

specify the order and which colour will be used twice.

This eect can cause ne cracks or wrinkles to form on the label at the point of colour transition.

Not possible to add splatters.

Colours can merge at the transition. Again, on rare occasions there may be a sound quality disparity

as playback crosses one colour to the other.

EFFECT #7 - TWISTED STRIPE

Possible as a 2 or 3 colour option, this is an interesting and diverse eect, made by laying a twisted

snake like puck across any base colour.

It is recommended to use contrasting solid colours to make the eect stand out as much as possible, and

the size of the central stripe is dependent on the combination of colours used. It is not recommended

to use a solid base with transparent twist as the twist may not be visible on both sides of the record.

The eect may not always look like a small stripe across the record as some combinations of colours

will create larger, morphing and entangled shapes as the various colours cross each other.

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

Not possible to add splatters.

Available on 12” only.

EFFECT #8 - MARBLE

A set range of striking colour combinations are available to produce this eect. Other colour

combinations may be achievable so please check with your contact to see if the combination of

colours you would like are possible.

Available on 10” and 12”.

EFFECT #9 - STARBURST

Similar in outcome to side the A/B eect or colour in colour, this eect is made by placing 3 pucks on

top of each other. It is possible to use combinations of solid and transparent colours, but we generally

advise solid contrasting colours to ensure all are as visible as possible.

Tip: Use a combination of primary colours which can mix to make even more colours.

This eect is not available for 7” vinyl, unless you specically use smaller central labels.

Not possible to add splatters.

EFFECT #10 - ECO MIX / LUCKY DIP

For those on a budget and/or who wish to minimise ecological impact, for the same price as black

vinyl you can have a completely Lucky Dip vinyl colour made using recycled materials!

What colour will it be? It’s impossible to say. You cannot request a specic colour and we cannot

predict it before it arrives on your doorstep! But we can tell you that the results are unique, not to

mention ecofriendly!

One of the most interesting aspects of the Lucky Dip vinyl colour option is that in most cases the nal

product will feature a marbled eect where it has been mixed with other colours.

EFFECT #11 - CORNETTO

This eect can have up to six wedges. For best results, we recommend a solid base colour plus solid

wedge colours, or a transparent base colour with transparent wedges though a contrasting darker

solid will work too.

We generally do not recommend choosing a solid base colour with transparent wedge colours.

Please be aware that the eect might only be visible on one side, and the other side will be random

and unpredictable.

If you choose a transparent base colour plus a solid wedge colour, the solid colour may ood the

transparent colour, especially if having ve or six wedges.

Not possible to add splatters.

EFFECT #12 - GALAXY

Very similar to our Marble/Smoke eect, except with deeper colour diusion due to increased

composite ratios used during production. It is not possible to have splatters on top of this eect; two

or three colours can be used though, and we advise contrasting colours for best results. We do not

recommend using a combination of transparent colours.

Not possible to add splatters.

Available on 12” only.

EFFECT #13 - SPINNER

A similar eect to Cornetto, here you will see three spokes which works best with a combination of a

lighter and darker colour; we advise a transparent base colour with solid or transparent spokes. If two

solid colours are used, the eect will not be visible enough from both sides.

You can add up to two splatters to the second colour (not the base colour).

Available on 12” only.

EFFECT #14 - TRIPLE-BUTTONS

Yet another two colour eect that again works best as a combination of a lighter colour and a

contrasting darker colour. The best colour combination to use is a transparent base with a solid

middle colour. It can also work with two transparent colours but it is important to use contrasting

colours. It is not recommended to use a solid base and transparent middle colour.

Not possible to add splatters.

Available on 12” only.

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

EFFECT #15 - MOON PHASE

The nal two colour eect that yet again works best as a combination of a lighter colour and

contrasting darker colour; this one can also be adorned with additional splatter colours. It is not

recommended to use a solid body colour with transparent moons, or a solid base colour and solid

moons, as the eect will not be visible enough from both sides.

Available on 12” only.

EFFECT #16 - BUTTERFLY

Last of the three colour eects, it is essentially very similar to Quad, but with a thinner bulging centre

to give the impression of wings. A combination of solid and transparent colours can be used, we

recommend a light transparent base colour (body), with a darker second colour (wings). It is not

recommended to use a solid body colour with transparent wings, as the eect may not be visible

form both sides. You can have a maximum of two splatter colours added to the second colour (not

the base colour).

Available on 12” only.

EFFECT #17 - GLOW IN THE DARK

Glow in the dark (GID) vinyl is available as a #14 or #15 clear base with added GID pigment. The GID

pigment is a powder that turns the clear records milky white in the daylight, with a green glow in the

dark. When viewed against the light, it is possible to observe a lack of colour spill which is caused by

the luminous pigment. Added splatters are possible on this eect.

EFFECT #18 - CLOUDY

The cloudy eect oers a liquid like feel, which is created by merging a clear compound with two

other colours (transparent ones work best). The rst additional colour determines the overall colour

of the record and the second colour determines the cloudy look. Please discuss the combination of

colours carefully with your account manager.

Added splatters are possible on this eect.

COLOUR DISCLAIMER

Please be aware of potential audio problems when ordering #15 ultra-clear, #17 Slade Boot Silver

and #18 Gold Digger. There is a risk that problems, such as audible clicks, will be present on the nal

pressed vinyl (even if not present on test pressings, as TP’s are supplied on the black vinyl compound

only). The reason for this is down to the compound material of these colours. Much of the time these

issues can be disguised by the music, but we cannot guarantee this until the records are actually

pressed. It is a small risk but can happen and it is your risk to take.

EFFECT DISCLAIMER

Sadly, there can always be audible issues on coloured vinyl with eects. Compared to black and

frosted clear vinyl the colour compounds do have a degrading eect on audio quality and eects

can cause audible clicks or pops and added hiss/surface noise. Sometimes it can be the specic

combination of certain colours and eects that cause issues and it is not possible for us to know until

the records are pressed, unless we have done that specic combination before.

Because of the nature of coloured vinyl compounds homogenous or heterogeneous structure, in

cases of multicoloured congurations the combinations of dierent types of coloured compound

can mean the audio quality may be aected in random and unpredictable ways, this may also vary

across an entire run.

If in any doubt we recommend black vinyl for optimum sound quality.

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

3.2 Etched vinyl

The etched area cannot be combined with audio so must be on a mirrored surface. A label must be

used on both sides of the record to prevent warping (a small one can be used on the etched side).

The etched surface is matt, and may have a patchy appearance.

3.3 Picture discs

RISKS AND RECOMMENDATIONS: : The vinyl record with a full or shaped label on both sides covered

by a plastic foil with pressed-in grooves. Two labels are used.

If recording is required on one side of the PD only, then there cannot be a “mirror” (smooth surface

without recording) on the other side, but there must be a “silent groove” (groove without signal).

The addition of a ‘silent groove’ is required even if the record does not cover the entire surface of

the record (prevention of label tearing, elimination of foil wrinkling and record curling). 12” PDs are

produced as heavy vinyl only. The PDs may show defects in the form of smudges (folded, wrinkled

foil).

Wrinkled foil occurs particularly in areas where there is no label between the foil and the compound.

If the legibility of the text is not aected or the label design is not signicantly deformed, this cannot

be the subject of a claim. Furthermore, as a result of the recording being made in a non-standard

material, this type of record may exhibit impaired acoustic properties, in particular increased noise

and crackling. These deteriorated acoustic properties cannot be the subject of a claim. Nor can a PD

record containing moiré be classied as defective, because the moiré eect is caused by interference

between the grooves on the foil layer and the printing grid of the label, which is printed by oset

litho printing with a CMYK colour model using standard grids (175lpi).

3.4 Picture discs with full-width labels

If they are to be oriented according to the customer’s wishes, they must be specied in order

(head to head).

3.5 Picture discs with shaped labels

The shape of the labels is limited. Please be aware that as the labels t on top of each other some

movement can occur between each side. The tolerance of mutual shift of labels is 5mm on the edge

of the label furthest from the centre. Production will try to limit this, but are not able to guarantee it.

Because we are not able to guarantee the exact position of both labels, if a clear or ultra-clear material

is to be used, we recommend that the label graphics on the reverse of the lead side, be matched in

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

colour to the face of the opposing label, which will help to minimise the visibility of label shift.

Some special records have a shaped label on one side and a circular label with a maximum diameter

of the inscribed circle (in the shape of the shape label) on the other.

3.6 Shaped discs

RISKS AND RECOMMENDATIONS: A record that is cut into various geometric shapes by milling. The

shapes of the record are determined by the customer through a drawn le. The minimum radius

of a shape/angle that can be used is 3mm. When determining the shape of the record, it is usually

necessary to base the record on a 12” or 10”, format, leaving intact a minimum diameter of 175mm

centric with a central hole (see following gure). In the case of a shaped PD, these are only produced

as 12” heavy weight vinyl.

3.7 Shaped picture discs

The semi-nished product for a shaped PD is PD with shaped labels, see section 3.5. In case of a variant

with two identical non-circular labels, these must be a minimum of 8mm smaller than the required

cut. The trimming is governed by the label on side A. Due to the tolerance of label positioning, this

means that the label on side B does not need to be centred to the trimming. This asymmetry in the

distance of the edge of the label from the edge of the record cannot be the subject of a claim. In case

of the variant with one shape and one circle label, the shape label must be 2-3mm smaller than the

required bleed. The trimming is governed by the shape of the label. These records are subject to all

the exceptions to the properties listed in Section 3.3. Also note that the record area limitations result

in a proportionately shorter playing time.

3.8 Shaped disc - classic disc

The blank for the moulded record is a conventional record (meaning not PD) of 10” or 12” size,

standard weight or heavy records.

3.9 Picture disc shape

RISKS AND RECOMMENDATIONS: : The records have degraded acoustic properties, for example

increased noise and crackling. Classical music or music with long quiet passages is not suitable for

this type of record.

The PD label must be at least 3mm smaller than the required shape. Only one-sided PDs can be

shaped, which always leads to deformation of the record. The shape of the label shall not contain

radii smaller than 3mm. The shape of the label should not contain narrow areas which risk cracking of

the label. The curvature of double-sided label records can be up to 5mm maximum. For complicated

shapes, the label prole must be tested by the pressroom technologist before the main production

is ordered.

NOTE: For the production of records according to 3.3 and consequently 3.7, TPs with white labels of

the shape corresponding to the order must be ordered and the main production must match the

sample production exactly, with no alterations or additional testing would be required.

Continue to the next page

www.discmanufacturingservices.com Tel: +44 (0)1752 201275 Email: info@discmanufacturingservices.com

Disc Manufacturing Services Limited, Second Floor, Prideaux Court, Palace Street, Plymouth, PL1 2AY | Registered in England & Wales no: 5127922 VAT no: 838 5310 21

STANDARD

Label does not contain ne detail.

POSSIBLE ISSUE

The label is too narrow and has cracked/split.