U.S. Department

of Transportation

Federal Aviation

Administration

Advisory

Circular

Subject: Guide for Developing and

Evaluating Repair Station and

Quality Control Manuals

Date: 10/6/17 AC No: 145-9A

Initiated by: AFS-300 Change:

This advisory circular (AC) provides informational material for all repair station certificate

holders and/or applicants under Title 14 of the Code of Federal Regulations (14 CFR) part 145 to

develop and evaluate a Repair Station Manual (RSM) and Quality Control Manual (QCM). This

AC describes an acceptable, but not the only means, to develop a manual and comply with the

referenced regulations.

John S. Duncan

Executive Director, Flight Standards Service

10/6/17 AC 145-9A

ii

CONTENTS

Paragraph Page

Chapter 1. General Information .................................................................................................. 1-1

1.1 Purpose .......................................................................................................................... 1-1

1.2 Cancellation .................................................................................................................. 1-1

1.3 Related 14 CFR Parts .................................................................................................... 1-1

1.4 Definition of Terms ....................................................................................................... 1-1

1.5 Background ................................................................................................................... 1-4

1.6 Where You Can Find This AC ...................................................................................... 1-4

1.7 AC Feedback Form ....................................................................................................... 1-4

Chapter 2. Manual Contents and Format .................................................................................... 2-1

2.1 The Manual(s) ............................................................................................................... 2-1

2.2 Combining Portions of the RSM with the QCM........................................................... 2-4

2.3 Identification and Control of Sections .......................................................................... 2-5

2.4 Sample Procedure Formats ........................................................................................... 2-6

Chapter 3. Manual Revision and Control ................................................................................... 3-1

3.1 Procedures for Revision ................................................................................................ 3-1

3.2 Provisions of Control .................................................................................................... 3-2

3.3 Electronic Format .......................................................................................................... 3-2

Chapter 4. Repair Station Organizational Chart ......................................................................... 4-1

4.1 Organizational Chart ..................................................................................................... 4-1

4.2 Duties and Responsibilities ........................................................................................... 4-2

Chapter 5. Repair Station and Quality Control Manual Elements .............................................. 5-1

5.1 Repair Station Personnel Roster ................................................................................... 5-1

5.2 Operations, Housing, Facilities, Equipment, and Materials ......................................... 5-3

5.3 Capability List (CL) ...................................................................................................... 5-6

5.4 Training Program Revision ........................................................................................... 5-8

5.5 Work Performed at Another Location .......................................................................... 5-9

5.6 Maintenance, Preventive Maintenance, and Alterations Performed for

Air Carriers Under 14 CFR Parts 121, 125, 129, and 135 .......................................... 5-14

5.7 Contract Maintenance Information ............................................................................. 5-18

5.8 Proficiency of Inspection Personnel ........................................................................... 5-23

10/6/17 AC 145-9A

iii

5.9 Current Technical Data ............................................................................................... 5-25

5.10 Inspection and QC System ........................................................................................ 5-28

5.11 Required Records and Recordkeeping ...................................................................... 5-38

5.12 Calibration of Measuring and Test Equipment ......................................................... 5-41

5.13 Taking Corrective Action on Deficiencies ................................................................ 5-45

Appendix A. Forms .................................................................................................................... A-1

Appendix B. Checklist ................................................................................................................B-1

List of Figures

Figure 2-1. Example Structure of a Single Manual System ...................................................... 2-5

Figure 2-2. Sample Procedure Format 1 .................................................................................... 2-7

Figure 2-3. Sample Procedure Format 2 .................................................................................... 2-8

Figure 2-4. Sample Procedure Format 3 .................................................................................... 2-9

Figure 2-5. Sample Procedure Format 4 .................................................................................. 2-11

Figure 4-1. Example Repair Station Organizational Charts ...................................................... 4-1

Figure 4-2. Narrative Format Sample ........................................................................................ 4-2

Figure 4-3. Outline/List Format Sample .................................................................................... 4-3

Figure 4-4. ISO/Industry Format Sample .................................................................................. 4-3

Figure 5-1. Roster Format Example 1 ....................................................................................... 5-2

Figure 5-2. Roster Format Example 2 ....................................................................................... 5-3

Figure 5-3. Roster Format Example 3 ....................................................................................... 5-3

10/6/17 AC 145-9A

1-1

CHAPTER 1. GENERAL INFORMATION

1.1 Purpose. This document is a guide for developing and evaluating the Repair Station

Manual (RSM) and Quality Control Manual (QCM) required by Title 14 of the Code of

Federal Regulations (14 CFR) part 145, §§ 145.207 through 145.211. This guide does not

provide a complete sample RSM and QCM for all repair stations. The examples included

illustrate one of many possible ways to comply with the regulations.

1.2 Cancellation. This advisory circular (AC) cancels AC 145-9 CHG 1, Guide for

Developing and Evaluating Repair Station and Quality Control Manuals,

dated March 19, 2009.

1.3 Related 14 CFR Parts. Parts 1, 21, 33, 39, 43, 65, 91, 121, 125, 129, 135, and 145.

1.4 Definition of Terms.

1.4.1 Acceptable. Data that meets the requirements of the applicable regulations.

1.4.2 Accountable Manager. The person designated by the certificated repair station (CRS)

who is responsible for and has the authority over all repair station operations that are

conducted under part 145, including ensuring that repair station personnel follow the

regulations and serving as the primary contact with the Federal Aviation

Administration (FAA).

Note: The FAA’s definition of an accountable manager may differ from the

European Aviation Safety Agency’s (EASA) definition of an accountable

manager; however, one person may serve both positions.

1.4.3 Approved. Approved, unless used with reference to another person, means approved by

the FAA or any person to whom the FAA has delegated its authority in the matter

concerned; or approved under the provisions of a bilateral agreement between the

United States and a foreign jurisdiction.

Note: For the FAA aviation safety inspector (ASI), “approved” or “approved by”

means the item has been formally approved by the FAA (or appropriate Civil

Aviation Authority (CAA)). Approvals are granted by letter, by a stamp of

approval, by the issuance of operations specifications (OpSpecs), or by other

official means.

1.4.4 Article. An aircraft, airframe, aircraft engine, propeller, appliance, or component part.

1.4.5 Capability List (CL). A CL is a list of articles by make and model or other nomenclature

in which the repair station is rated to perform maintenance, preventive maintenance, or

alterations.

10/6/17 AC 145-9A

1-2

1.4.6 Contract Maintenance. Entering into an agreement between the originating CRS and

another person or entity (FAA certificated or noncertificated) to perform maintenance

functions on an article. The originating repair station will exercise the privileges of its

certificate and assume responsibility for the work performed by the contracted person or

entity.

1.4.7 Correction. A correction is an action to eliminate an identified nonconformity as it relates

to the articles or the maintenance processes.

1.4.8 Corrective Action. Corrective action is an action to eliminate the cause of an identified

nonconformity or other undesirable condition to prevent its recurrence. An example of a

corrective action could be accomplished as a proactive initiative, such as a technically

conforming article could be removed because of an upcoming life limit.

1.4.9 Designated Engineering Representative (DER). A private person designated by the FAA

Administrator to act as its representative for examining, inspecting, and testing aircraft

and related data. A DER may recommend approval or approve data within the limitations

of his or her Certificate of Authority (COA).

1.4.10 Directly in Charge. Having the responsibility for the work of a CRS that performs

maintenance, preventive maintenance, alterations, or other functions affecting aircraft

airworthiness. A person directly in charge does not need to physically observe and direct

each worker constantly, but must be available for consultation on matters requiring

instruction or decision from a higher authority.

1.4.11 Line Maintenance. Line maintenance is any unscheduled maintenance resulting from

unforeseen events, or scheduled checks that contain servicing and/or inspections that

do not require specialized training, equipment, or facilities.

1.4.12 Maintenance. Inspection, overhaul, repair, preservation, and the replacement of parts,

excluding preventive maintenance.

1.4.13 Maintenance Function. A step or series of steps in the process of performing

maintenance, preventive maintenance, or alterations.

1.4.14 Major Alteration. An alteration not listed in the aircraft, aircraft engine, or propeller

specifications that:

1. Might appreciably affect weight, balance, structural strength, performance,

powerplant operation, flight characteristics, or other qualities affecting

airworthiness; or

2. Is not done according to accepted practices or cannot be done by elementary

operations.

10/6/17 AC 145-9A

1-3

1.4.15 Major Repair. A repair that:

1. If improperly done, might appreciably affect weight, balance, structural

strength, performance, powerplant operation, flight characteristics, or other

qualities affecting airworthiness; or

2. Is not done according to accepted practices or cannot be done by elementary

operations.

1.4.16 Mobile Field Service. Repair station personnel, materials, tools, and equipment deployed

to perform work away from the fixed location for a special circumstance and/or for

recurring work.

1.4.17 Mobile Maintenance Unit. A vehicle deployed by the repair station to transport materials,

equipment, data, and personnel from one location to another.

1.4.18 Operations Specifications (OpSpecs). The official documents that describe the

authorizations, ratings, and limitations of the repair station.

1.4.19 Preventive Maintenance. Simple or minor preservation operations and the replacement of

small standard parts not involving complex assembly operations.

1.4.20 Procedure. A specified way to perform an activity or a series of steps, such as a procedure

that describes the methods, steps, or means to carry out policy. A procedure should

include who performs each task and when, where, and how the task is performed.

1.4.21 Quality Control Manual (QCM). A manual that describes the inspection and quality

control (QC) procedures used by the repair station.

1.4.22 Rating. A part of the repair station’s certificate that describes the special conditions,

privileges, or limitations issued under § 145.59 and/or § 145.61.

1.4.23 Repair Station Manual (RSM). A manual that describes the procedures and policies of a

repair station’s operations.

1.4.24 Required Inspection Item (RII). The requirement to inspect an item of maintenance that,

if not performed properly, or is done with improper parts or materials, could result in a

failure, malfunction, or defect, endangering the safe operation of the aircraft. An RII must

be inspected by a trained, qualified, and authorized inspector. The inspector must be

listed on the repair station’s roster but cannot be the same individual who performed the

work. (Refer to part 121, § 121.371; part 125, § 125.251; and part 135, § 135.429 for

details of this requirement.)

1.4.25 Supervisor. Person or persons employed by the repair station that direct the work

performed under the repair station certificate and OpSpecs. The supervisor must also

oversee the work performed by any individuals who are unfamiliar with the methods,

techniques, practices, aids, equipment, and tools used to perform the maintenance,

preventive maintenance, or alterations.

10/6/17 AC 145-9A

1-4

1.4.26 Temporary/Temporarily. Transient; an arrangement without permanency, lasting for a

limited time.

Note: The phrase “temporary transport” (especially as it relates to § 145.203(b) of

the rule) is not defined or explained in the regulation or the preambles. An

unspecified return-to-base frequency cannot be read into the current rule.

1.4.27 Traceability. The ability to verify the history, location, or application of an item by means

of documented recorded identification.

1.4.28 Tracking. A method developed and utilized by the certificate holder to identify the

location of work being performed away from the fixed location (by mobile field services,

maintenance units, or other means).

1.5 Background. The FAA has revised this AC to incorporate policies and procedures

identified in related FAA guidance for clarity and consistency. It also clarifies the

minimum requirements for an RSM and QCM and provides guidance for items that

should be included in these manuals. The RSM and QCM are essentially a “living”

manual system. When regulations change or FAA guidance is revised, as well as when

the repair station’s procedures and operations change, the manual(s) and procedures need

to be reviewed, revised, and followed. Although repair stations range from very small

(e.g., 1–2 person) operations to very large (e.g., 1,000+ person) repair stations, the

suggested procedures within this AC should assist repair stations of all sizes in designing

procedures that meet the intent of the regulations and its individual operations.

1.6 Where You Can Find This AC. You can find this AC on the FAA’s website at

http://www.faa.gov/regulations_policies/advisory_circulars.

1.7 AC Feedback Form. For your convenience, the AC Feedback Form is the last page of

this AC. Note any deficiencies found, clarifications needed, or suggested improvements

regarding the contents of this AC on the Feedback Form.

10/6/17 AC 145-9A

2-1

CHAPTER 2. MANUAL CONTENTS AND FORMAT

2.1 The Manual(s).

2.1.1 Combining Information. The applicant/certificate holder may combine portions required

by § 145.209 with portions required by § 145.211 into one section or chapter of the

manual system. For example, the procedures required in § 145.209 for RSM revision and

the procedures required in § 145.211 for QCM revision could be combined into one

chapter/section titled “Manual Revision.” The manual(s) content must include procedures

required by the regulations, but may be formatted in any manner easily understood by

employees of the repair station.

2.1.2 Accessibility. The repair station’s current RSM must be accessible for use by

repair station personnel required by part 145 subpart D, as stated in § 145.207.

Section 145.211 includes a QC system in which the CRS must prepare and keep current a

QCM and requires repair station personnel to follow the QC system.

2.1.3 Checklist. Appendix B, Checklist, may be used to assist the applicant/certificate holder in

reviewing the content of its manual(s). All items listed on the checklist may not be

applicable to each repair station due to differences in ratings, sizes, and types of

maintenance performed.

2.1.4 Submit the Manual. The applicant/certificate holder may submit the manual(s) to the

responsible Flight Standards office on paper or electronically. If the repair station submits

the manual as part of an initial certification, the manual may be submitted together with

related documents, such as the application form and repairmen applications, to the

responsible Flight Standards office. If the repair station submits the manual

electronically, they should discuss the format, software, and revision procedures with the

responsible Flight Standards office before submittal. The repair station must follow the

procedures described in its manual when submitting revisions to an existing manual (see

Chapter 3, Manual Revision and Control).

2.1.5 Required Content. The basic regulatory requirements for manual content are listed below

and will be discussed in detail in the following sections of this AC.

2.1.5.1 RSM Elements.

1. Manual Revision and Notifying the Responsible Flight Standards

Office. Procedures for revising the RSM and notifying the

responsible Flight Standards office of revisions to the manual,

including how often the office will be notified of the revisions

(refer to § 145.209(j)).

2. Identification and Control of Sections of the Manual. A description

of the system used to identify and control sections of the RSM

(refer to § 145.209(k)).

10/6/17 AC 145-9A

2-2

3. Organizational Chart (§ 145.209(a)). An organizational chart

identifying:

• Each management position with authority to act on behalf of the

repair station.

• The areas of responsibility assigned to each management position.

• The duties, responsibilities, and authority of each management

position.

4. Rosters. Procedures for maintaining and revising the rosters

required by § 145.161 (refer to § 145.209(b)).

5. Housing and Facilities:

• A description of the housing (refer to § 145.209(c)). For example, this

may include dimensions, construction method, heating, ventilation

systems, environmental protection, lighting, door openings, and

physical address.

• A description of the facilities, including the layout of the shop, hangar,

work areas, segregation areas, material storage, or machining.

• A description of the equipment, tooling, and materials used to perform

maintenance (refer to § 145.209(c)).

Note: The description of materials used to perform maintenance

should not be a physical description of the material, but rather an

explanation of the repair station’s handling and storage of the

materials. If materials require specific environmental controls or

cannot be stored next to certain chemicals or solvents, these should

be identified. For example, it would not be acceptable to store

oxygen equipment near petroleum products.

• If the repair station does not own the equipment, tools, and materials

necessary to perform the maintenance, preventive maintenance, or

alterations under its repair station certificate and OpSpecs in

accordance with part 43, include procedures in the manual that

describe how the repair station will obtain them (lease, rentals, etc.).

6. CL. Procedures for (if applicable):

• Revising the CL provided in §§ 145.209(d)(1) and 145.215.

• Responsible Flight Standards office notification of revisions to the list,

including how often the repair station will notify the office of revisions

(refer to § 145.209(d)(1)).

• Performing the self-evaluation required by §§ 145.209(d)(2)

and 145.215(c), including methods and frequency of such evaluations

and procedures for reporting the results to the appropriate manager for

review and action.

10/6/17 AC 145-9A

2-3

7. Training Program. Procedures for revising the training program

and submitting revisions to the responsible Flight Standards office

for approval, in accordance with the procedures required by

§ 145.209(e).

8. Procedures Governing Work Performed at Another Location

(§ 145.209(f)):

• The work is necessary due to a special circumstance, as identified in

§ 145.203(a); or

• The work is performed on a recurring basis and the RSM includes

procedures for accomplishing the work at a place other than the repair

station’s fixed location, as identified in § 145.203(b).

9. Procedures for Maintenance, Preventive Maintenance, or

Alterations Performed Under § 145.205 (if applicable). Procedures

for performing maintenance, preventive maintenance, and

alterations for certificate holders under parts 121, 125, and 135,

and for foreign air carriers or foreign persons operating a

U.S.-registered aircraft in common carriage under part 129

(refer to § 145.209(g)).

10. Contract Maintenance Procedures. Procedures for:

• Maintaining and revising the contract maintenance information

required by § 145.217(a)(2)(i), including submitting revisions to the

responsible Flight Standards office for approval (refer to

§ 145.209(h)(1)).

• Maintaining and revising the contract maintenance information

required by § 145.217(a)(2)(ii) and notifying the responsible Flight

Standards office of revisions to this information, including how often

the office will be notified of revisions (refer to § 145.209(h)(2)).

11. Required Records and Recordkeeping System. A description of the

required records and the recordkeeping system used to obtain,

store, and retrieve the required records per §§ 145.209(i)

and 145.219.

2.1.5.2 QCM Elements.

1. Revision Procedures and Notifying the Responsible Flight

Standards Office. Refer to § 145.211(d).

2. Qualifying and Surveilling Noncertificated Persons Performing

Maintenance, Preventive Maintenance, or Alteration for the Repair

Station. Refer to § 145.211(c)(1)(vi).

3. Establishing and Maintaining Proficiency of Inspection Personnel.

Refer to § 145.211(c)(1)(iv).

10/6/17 AC 145-9A

2-4

4. Establishing and Maintaining Current Technical Data. Refer to

§ 145.211(c)(1)(v).

5. Inspection System. Description and procedures for (refer to

§ 145.211(c)(1)(i), (ii), (iii), and (vii)):

• Inspecting incoming raw materials.

• Performing preliminary inspection of all articles that are maintained.

• Inspecting all articles that have been involved in an accident for

hidden damage before maintenance, preventive maintenance, or

alteration is performed.

• Performing final inspection and return to service.

6. Calibration of Measuring and Test Equipment, Including Intervals

of Calibration. Refer to § 145.211(c)(1)(viii).

7. Taking Corrective Action on Deficiencies. Refer to

§ 145.211(c)(1)(ix).

8. References. References, where applicable, to the manufacturer’s

inspection standards for a particular article, including reference to

any data specified by that manufacturer (refer to § 145.211(c)(2)).

9. Samples of Inspection Forms and Instructions for Completion.

May be a separate manual (refer to § 145.211(c)(3)).

10. Portions Recommended for Manual Organization:

• Table of Contents.

• List of Effective Pages (LEP).

• Record of Revisions.

2.2 Combining Portions of the RSM with the QCM.

2.2.1 Possible Combination. Figure 2-1, Example Structure of a Single Manual System,

illustrates one of several possible combinations that applicants/certificate holders could

use to structure a single manual system. It includes the procedures required in both the

RSM and the QCM. Other combinations may be possible depending upon the ratings,

size, and complexity of the repair station. The manual’s content must include the

applicable procedures required by the regulations, but may be formatted in any manner

easily understood by employees of the repair station.

10/6/17 AC 145-9A

2-5

Figure 2-1. Example Structure of a Single Manual System

Repair Station Manual

Element

+

Quality Control Manual

Element

=

Possible

Chapter/Section

Title

Training program,

revision, notifying

responsible Flight

Standards office

+

Establishing and

maintaining proficiency

of inspection personnel

=

Training

Maintaining and revising

contract information

+

Qualifying and surveilling

noncertificated persons

=

Contract Maintenance

Manual revision,

responsible Flight

Standards office

notification,

identification, and control

of sections

+

Manual revision and

responsible Flight

Standards office

notification

=

Manual Control

Records and

recordkeeping system

+

Establishing and

maintaining current

technical data

=

Document Control

Etc.

+

Etc.

=

Etc.

2.2.2 Meeting Manual Requirements. The repair station should include a table referencing the

manual contents listed in §§ 145.209 and 145.211 to clearly identify that the RSM and

QCM meet regulatory requirements.

2.3 Identification and Control of Sections.

2.3.1 Page Numbering. Sequential numbering of the manual(s) from front to back may cause

difficulty for the revision process. A minor revision to one of the first pages may cause a

change in the content of each successive page. The FAA advises the repair station to

divide the manual into several sections, so that a revision to one page of a section does

not affect the entire manual.

2.3.2 Related Subject Matter. Most RSMs are divided into sections of similar subject matter.

For instance, one section of the manual may contain all of the procedures related to the

inspection system. The repair station may establish these sections, or the sections may be

contained within an established industry format (such as the International Organization

for Standardization (ISO)). The sample formats included in this chapter contain a few

examples of the many possible methods used for identification. The sections may consist

of several similar individual procedures grouped together through a common numbering

system, or several similar procedures described in narrative format within a section.

Regardless of the method used, each section must be identified and controlled.

10/6/17 AC 145-9A

2-6

2.3.3 Table of Contents. Many RSM sections are controlled using a table of contents. The table

of contents lists each section of the manual and the location in the manual. Some

repair stations choose to reissue a complete section of the manual if any page within that

section is revised. The table of contents for those facilities may indicate revision status

for each section, rather than each page.

2.3.4 Master Document Control List. Some RSMs are controlled using a master document

control list. This document lists each procedure and the revision status of that procedure.

A unique number and revision status should identify each procedure within the manual

system. If a page within a procedure is revised, the entire procedure is reissued. In this

system, each procedure is identified and controlled, rather than each section.

2.3.5 Section Control. The procedures to control sections of the manual should address

(as applicable):

• Identification;

• Revision status;

• Page numbering;

• Issue date; and

• Approvals of internal personnel responsible for the manual and revisions.

2.3.6 Additional Combinations. Additional combinations that work effectively within the

facility and are acceptable to the FAA principal inspector (PI) may be included in the

manual system.

2.4 Sample Procedure Formats. The following samples are provided to help the manual

writer determine a possible format for the procedures in the manual system. These are

only four examples of many possible formats. Part 145 sets the requirements for content,

not format. The format used for the procedures in the manual should fit the size and

complexity of the facility. If there are existing procedure manuals in the facility, the

manual writer may wish to include the same format in the RSM(s). If facility employees

are accustomed to a particular format, the manual writer should continue to use that

format.

10/6/17 AC 145-9A

2-7

Figure 2-2. Sample Procedure Format 1

2.4.1 Format 1 Discussion.

2.4.1.1 Advantages. Figure 2-2, Sample Procedure Format 1, includes each of the

six Safety Assurance System (SAS) safety attributes to assist in designing a

procedure in a narrative format. This format is easy to write, as long as the

author remembers to include all of the safety attributes. This format is usually

easy for the reader to understand and requires no special training for the

author or reader.

2.4.1.2 Disadvantages. The narrative can easily become too complex or wordy. The

author may fail to include all of the safety attributes of the procedure. The

narrative must be presented in a logical sequence so the reader can easily

understand the flow of the procedure.

10/6/17 AC 145-9A

2-8

Figure 2-3. Sample Procedure Format 2

THE JOHN SMITH COMPANY OPERATING PROCEDURE 123

Title: Receiving Inspection Page 1 of 4

Revision: A Issue Date: November 12, 2001

---------------------------------------------------------------------------------------------------------

Reason: To ensure consistent quality of incoming raw material.

Scope: Applies to all raw material shipments received. This procedure does not apply to

incoming parts received for repair.

Responsibility: The receiving inspector is responsible for inspecting all incoming raw

materials.

Procedure:

1. The receiving inspector will visually inspect the container (if used) and/or material

for any shipping or handling damage.

2. The receiving inspector will immediately report any shipping or handling damage to

the purchasing department.

3. Compare the purchase order (copy located in receiving file) with the shipping

document to ensure the material is correct.

4. Etc.

2.4.2 Format 2 Discussion. Figure 2-3, Sample Procedure Format 2, assigns responsibility as

part of each procedure. The narrative should be written in a format easily understood by

the person who uses and must follow the procedure. Note that the format also includes

revision status, issue date, and page numbering. The reason and scope may be used to

state the company policy or objective.

10/6/17 AC 145-9A

2-9

Figure 2-4. Sample Procedure Format 3

John Smith Overhaul & Repair

Quality Procedure—Control of Inspection, Measuring, and Test Equipment

QP 4.11

Approval

Approval

Revision/Date

Reason for Change

John Smith, Sr.

Jane Doe

Original—04/01/2000

Original issue

John Smith, Sr.

Jane Doe

A—06/15/2000

Added gage request

form

1.0 Purpose: To ensure that all precision tools and equipment are properly calibrated,

identified, and maintained.

2.0 Scope: This procedure applies to all employees who use inspecting, measuring, and

testing equipment, and those who calibrate that equipment.

3.0 Responsibility: The Director of Quality is responsible for ensuring that all inspecting,

measuring, and testing equipment is calibrated and traceable. Only trained and qualified

personnel are permitted to adjust and calibrate equipment.

4.0 Reference Documents:

4.1 QAP 15.0, Inspection and Test Status.

4.2 MIL-STD-120 Gage Inspection.

4.3 Work Instruction (WI) 4.11-1 through WI 4.11-20.

5.0 Definitions:

5.1 Accuracy of Measurement: The closeness of the agreement between the result

of a measurement and the conventional true value of the measurement.

5.2 Uncertainty of Measurement: The result of the evaluation aimed at

characterizing the range within the true value of a measurement. It’s estimated

to lie generally within a given likelihood.

5.3 Etc.

5.4 Etc.

6.0 Procedure:

6.1 The gage calibration technician will maintain a computerized list of all

precision tools and equipment using the Gage Control software program.

6.2 During the first week of the month, the gage technician should run the

“Calibration Required” report, listing all tools and equipment that must be

calibrated before the end of the month.

6.3 The gage calibration technician will issue a John Smith Recall Slip (Form 789)

to the department or individual. This form states which tools are due for

calibration and the date they must be returned to the tool crib.

6.4 Etc.

7.0 Records:

7.1 Form 789, Recall Slip.

7.2 Form 456, Record of Calibration.

7.3 Form 123, Identification Sticker.

7.4 Etc.

10/6/17 AC 145-9A

2-10

2.4.3 Format 3 Discussion. Figure 2-4, Sample Procedure Format 3, is often used for

procedures included in an ISO 9000 quality management system document. Note that

space is provided to document approval and release of the document (part of a document

control system). Terms used within the procedure are defined. Additional documents

associated with this procedure are listed. The format is structured (perhaps too structured)

for some organizations. The procedure follows a standard numbering system for each

portion of the procedure, allowing for precise reference for paragraphs that may be

discussed or revised. Work instructions and records may follow the same numbering

convention (e.g., QP 4.12, WI 4.12-1, and Form 4.12-A). Forms may be included within

the procedure or in a separate forms section of the manual system.

2.4.4 Introduction to Figure 2-5, Sample Procedure Format 4.

2.4.4.1 The following flowchart illustrates another possible method of presenting a

procedure. Although the sample illustrates a simple procedure, complex

processes could also be presented using a flowchart. The person using the

manual would need to be familiar and comfortable with flowcharts and

flowchart symbols.

2.4.4.2 The flowchart process may also be used to develop a procedure that was not

previously documented. The procedure could be initially drawn on paper

using a flowchart, and then described using the narrative format in the manual.

This process works well when the users of the manual are more comfortable

with narrative procedures rather than flowcharts.

2.4.4.3 Another possible use of the flowchart is to verify if a narrative procedure will

work. This process is essentially the opposite of the process previously

described. While reading the narrative of the procedure, a flowchart is created

to visually represent the various steps. A review of the completed flowchart

will show any redundant or missing steps.

2.4.4.4 A flowchart can also be used during a process audit. The auditor creates a

flowchart while reviewing the performance of a particular process. The

auditor then compares the process he or she observed with the process

described in the manual. Any differences may be noted in the auditor’s report.

2.4.5 Format 4 Discussion. Format 4 requires the reader to have some familiarity with

flowcharts, but can be easily understood by someone who understands the format.

Because the flowcharts contain fewer words than other formats, the process can be read

and understood quickly. This format takes longer to develop unless the author has

specific software for that purpose.

10/6/17 AC 145-9A

2-11

Figure 2-5. Sample Procedure Format 4

10/6/17 AC 145-9A

3-1

CHAPTER 3. MANUAL REVISION AND CONTROL

3.1 Procedures for Revision.

3.1.1 References. Title 14 CFR part 145:

• Section 145.207(e).

• Section 145.209(j).

• Section 145.209(k).

• Section 145.211(c)(4).

• Section 145.211(d).

3.1.2 Requirements. The RSM and the QCM must contain procedures for revising the

manual(s) and notifying the responsible Flight Standards office of revisions.

Note: The regulations do not require FAA review and acceptance of revisions

before implementation, provided the repair station follows the revision procedures

in its manual. The repair station should have a procedure in its manual to recall

revisions if the FAA finds a revision unacceptable.

3.1.3 Control Submissions and Revisions. This section of the manual must contain procedures

to control the original submission of the manual and subsequent revisions. The

procedures should ensure that persons issued a manual receive revisions. Repair station

employees may require training on the content of the revisions, especially if a standard

operating procedure (SOP) or inspection procedure is changed.

3.1.4 Control System Description. The manual must include a description of the system used to

identify and control sections of the manual. The format and structure of this system is not

specified by the regulation. This flexibility will accommodate the technological changes

that permit repair stations to maintain and revise the manuals in different formats and

manners.

3.1.5 Procedures. Regardless of the media used for the manual, the procedures for making

revisions should include:

1. A person who is clearly identifiable (by title) has the responsibility for the

quality of the process for making revisions.

2. A person who is clearly identifiable (by title) has the authority to set up and

change a process and will submit revisions to the FAA for review and

acceptance.

3. How will the repair station incorporate changes to revisions and document

methods to accomplish a process?

4. How will the repair station control revisions and submittals by checks and

restraints designed into the process to ensure the desired result?

10/6/17 AC 145-9A

3-2

5. Are the process measures used to validate a process and identify problems or

potential problems in order to correct them?

6. What interfaces and interactions between processes that must be managed in

order to ensure desired outcomes are there?

7. How will the repair station ensure that the RSM is accessible for use by repair

station personnel?

8. Identification of each revision to the text on each affected page. For example,

a vertical bar in the margin or other suitable method may indicate the revised

portion of text.

3.2 Provisions of Control. If the manual is in paper format, the revision and control part of

the manual should contain the following (or equivalent) information:

3.2.1 Revisions. Procedures for revising the RSM and notifying the responsible Flight

Standards office of revisions, including how the FAA will be notified of revisions.

3.2.2 Details. Provisions for selecting the revision number, the date of the revision, the pages

revised, and a place for the person making the revisions to the assigned manual to sign or

initial.

3.2.3 Manual Control Number and Assignment. Although the regulations do not state how

manuals should be controlled, they do state that a manual control should be included in

the procedures. The FAA suggests that each manual have a unique number assigned to it

and the name of the individual, department, or group assigned to that particular manual.

The manual procedure should identify who will maintain a master distribution list that

contains the manual number, assigned individual, and revision status.

Note: An acknowledgement form is a common method of tracking the receipt and

insertion of the revision by the manual holder, which ensures accountability. With

this method, after receiving a revision, each manual holder inserts the revised

pages into the manual, records incorporation of the revision in the record of

revisions, and returns the signed acknowledgement form to the person responsible

for manual control.

3.3 Electronic Format. The manual(s) may be maintained on a computer network or other

electronic medium. AC 120-78, Electronic Signatures, Electronic Recordkeeping, and

Electronic Manuals, provides additional guidance for electronic systems.

3.3.1 Network. If the manual is maintained on a network server, the following concerns should

be addressed in the procedures:

1. Security. How will the repair station ensure that only authorized personnel

make any changes? Who (by title) will be authorized to make those changes

and how is that person authorized?

10/6/17 AC 145-9A

3-3

2. Access. Have the employees been trained to access the manual on the

network? Is access protected by passwords? Do all of the supervisors and

inspectors have access to the manual?

3. Revisions. How will the user know that the manual has been revised, and the

content of that revision?

4. Availability. How will the repair station ensure that the current manual(s) are

available for all shifts? How will the repair station ensure that manual users

will have access to the manuals in the event of Internet or computer outages?

3.3.2 Disk. If the manual is maintained on a disk, the following concerns should be addressed

in the procedures:

1. How will the manual and any subsequent revisions be distributed? How will

receipt of the revision be documented?

2. Is the software used for writing the manual compatible with the software used

by all manual holders, including the FAA?

3. Are all of the manual holders trained on the procedures necessary to access

the manual at their workstations?

4. How can station personnel verify if the disks are current before they use

them?

Note: Federal agencies can no longer refuse electronic versions of manuals,

forms, record systems, etc. Federal law prohibits agencies from making the use of

electronic media more difficult, or from requiring additional steps or procedures

for users of electronic media.

10/6/17 AC 145-9A

4-1

CHAPTER 4. REPAIR STATION ORGANIZATIONAL CHART

4.1 Organizational Chart.

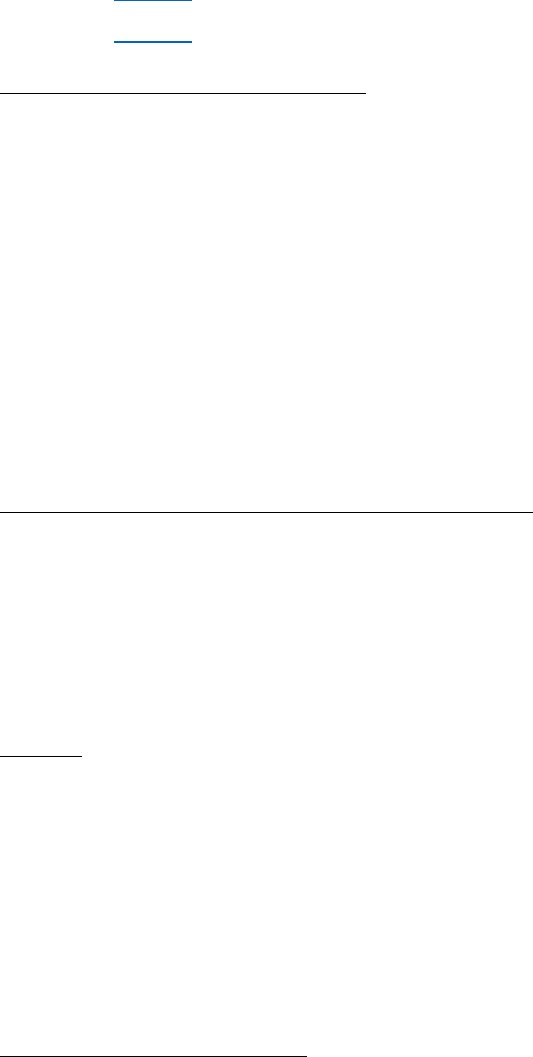

4.1.1 Reference. Title 14 CFR part 145, § 145.209(a).

4.1.2 Authority. The organizational chart identifies (by title only) each management position

with authority to act on behalf of the repair station. If the repair station performs work for

air carriers or air operators under § 145.205 and is performing Required Inspection Items

(RII), the FAA suggests that the chart reflect the separation between the maintenance and

inspection departments.

Figure 4-1. Example Repair Station Organizational Charts

4.1.3 Procedure Details. Ensure that the following concerns are addressed in the manual

procedures.

4.1.3.1 Are the titles and reporting structure for the organizational chart appropriate

for the facility?

4.1.3.2 Are the titles for the positions the same throughout the manual?

10/6/17 AC 145-9A

4-2

4.1.3.3 Is each management position with authority to act on behalf of the repair

station identified?

4.1.3.4 Is an accountable manager designated?

4.2 Duties and Responsibilities.

4.2.1 Organization. This section may be combined with the organizational chart as one

section/chapter of a manual system. If the repair station documents its procedures in a

format that includes a Responsibility section in each procedure, it will not need to have a

separate Duties and Responsibilities section (see Chapter 2, Figure 2-3, Sample

Procedure Format 2, and Figure 2-4, Sample Procedure Format 3).

4.2.2 Area of Responsibility. This section includes the area of responsibility assigned to each

management position and the duties, responsibilities, and authority of each management

position. Ensure that the duties and responsibilities are appropriate and that the positions

exist within the company. Although not required by the regulation, many repair stations

choose to include duties and responsibilities beyond the required management personnel.

Positions described in the organizational chart should be included in the Duties and

Responsibilities section to ensure consistency.

4.2.3 Additional Responsibilities. Duties and responsibilities that are outside the scope of the

management, but are part of the regulatory requirements, should be described in this

section of the manual (e.g., equipment maintenance, approval for return to service,

applications for repairmen, and so forth).

Note 1: Only titles, not names, should appear in this section. Titles should be the

same as on the organizational chart and elsewhere in the manual.

Note 2: Titles used in the following format samples are only examples.

Figure 4-2. Narrative Format Sample

Owner/President: The Owner/President is responsible for the overall operation

of (name of the repair station) in accordance with the applicable Code of Federal

Regulations (CFR). The Owner/President’s duties include maintaining an

adequate and knowledgeable staff to plan, perform, supervise, and inspect the

work being performed on civil aviation articles. The Owner/President may

delegate all duties to the qualified persons as necessary. However, such delegation

does not relieve the Owner/President of the overall responsibility.

10/6/17 AC 145-9A

4-3

Figure 4-3. Outline/List Format Sample

Quality Manager: The Quality Manager reports to the President and is

responsible for managing the repair station quality control (QC) system. The

duties of the Quality Manager include:

(1) Supervising all inspection personnel.

(2) Maintaining a current file of pertinent technical data, including CFRs,

specifications, manufacturer’s maintenance manuals, Service Bulletins (SB),

Airworthiness Directives (AD), and other data acceptable to or approved by the

FAA.

(3) Ensuring the proper execution of FAA Form 337, Major Repair and Alteration

(Airframe, Powerplant, Propeller, or Appliance), when required.

(4) Etc.

Figure 4-4. ISO/Industry Format Sample

The duties and responsibilities may be addressed in the management responsibility

section of the manual (i.e., section 4.1).

a. The following questions or concerns are offered as a guide and are intended to help the

facility initiate the procedures in its RSM. They should not be considered all-inclusive. Each

facility is unique and therefore may require additional procedures to verify regulatory

requirements and the needs of the repair station.

(1) Do the duties and responsibilities include the areas of responsibility assigned to each

management position?

(2) Do the duties and responsibilities indicate the reporting structure (to what other

position does each report)?

(3) Does the narrative describe the job function(s) that person performs (i.e., calibration,

training, personnel management)?

(4) Do the procedures ensure that the duties and responsibilities of supervisory and

inspection personnel are performed in their absence?

(5) Does the manual have a procedure to determine if a supervisor or inspector is

qualified for any delegated duties?

10/6/17 AC 145-9A

4-4

b. Consider the following when assigning duties and responsibilities within the

repair station:

(1) Is each supervisor certificated?

(2) Do the inspectors understand, read, and write English?

(3) Are persons with approval for return to service authority certificated?

10/6/17 AC 145-9A

5-1

CHAPTER 5. REPAIR STATION AND QUALITY CONTROL MANUAL ELEMENTS

5.1 Repair Station Personnel Roster.

5.1.1 References. Title 14 CFR part 145:

• Section 145.161.

• Section 145.209(b).

5.1.2 Records of Management, Supervisory, and Inspection Personnel. Personnel rosters are

lists of management and supervisory personnel that include repair station officials who

are responsible for its management and the names of its supervisors who oversee

maintenance functions. These rosters can be maintained in paper or electronic format, but

they must be made available to the FAA.

5.1.3 Roster Format. Each repair station may develop its own roster format, as long as it

contains all of the appropriate names and employment summaries of each individual

listed on the roster and required by § 145.161(a)(1) through (3).

5.1.4 Manual Inclusion. The rosters do not need to be included in the manual, but the

procedures for maintaining and revising the rosters must be in the manual. If the rosters

are not included in the manual, the procedure should describe how the roster will be made

available to the FAA. The procedure should describe how the roster will be revised

within 5 business-days when there is a change caused by termination, reassignment,

change in duties or scope of assignment, or addition of any personnel.

5.1.5 Combination Roster. Although not required by regulation, it may be appropriate for the

repair station to develop a combination roster, which would include initials, signatures,

stamp numbers, certificate numbers, or any other information used to designate the

authority of inspection or supervisory personnel who can sign/stamp off work documents

or approve articles for return to service.

5.1.6 Employment Summaries. The repair station must maintain employment summaries for

each person whose name appears on the rosters. Employment summaries are required by

§ 145.161(a)(4)(i) through (v), to include present title, total years of experience and the

type of maintenance work performed, past relevant employment with names of employers

and periods of employment, scope of present employment, and the type of mechanic or

repairman certificate held and the ratings on that certificate, if applicable.

5.1.7 Roster Procedures. The following questions should be answered during the development

of the procedures concerning the rosters:

1. Who is responsible (by title) for maintaining the rosters and employment

summaries in current condition? Has an alternate been designated?

2. Where will the rosters be located? How will the rosters be made available to

the FAA?

10/6/17 AC 145-9A

5-2

3. How will the rosters be revised within 5 business-days?

4. Is authority to approve an article for return to service shown on the rosters?

Who is responsible for designating those individuals, and how are those

individuals designated?

5. Are the managers, supervisors, inspectors, and persons authorized to approve

articles for return to service all listed on the rosters?

6. Are the supervisors certificated, and with what type of certificate?

7. Are the persons authorized to approve articles for return to service

certificated? (Each person authorized to approve articles for return to service

must be certificated under 14 CFR part 65, unless located outside the

United States.)

8. Are there employment summaries for each person on the roster?

5.1.8 Examples. The following are examples of possible roster formats.

Figure 5-1. Roster Format Example 1

10/6/17 AC 145-9A

5-3

Figure 5-2. Roster Format Example 2

Section: III

Date Completed: 11/13/2001

Revision No. 1

Personnel

Title: Chief Inspector/Repairman

Authorized Signature:

Kyle R. Bowman

FAA Airman Certificate Held: Repairman No. 123456789

Authorized to Sign: Logbooks and other approvals for return to service, Malfunction and

Defect Reports

Figure 5-3. Roster Format Example 3

John Smith Component Repair, Inc.

Effective Date: 11/13/2001

Supervisory and Inspection Personnel Roster

TITLE

NAME

CERT. TYPE & NO.

AUTHORITY

CEO

John Smith

N/A

N/A

Q.C. Manager

Jane Smith

Repairman 1234567

FPI, Machining

Foreman

Dan Jones

Repairman 98765432

Machining, Cleaning

Chief Inspector

David Jones

N/A

N/A

5.2 Operations, Housing, Facilities, Equipment, and Materials.

5.2.1 References:

• Title 14 CFR part 43.

• Sections 145.101 through 145.109.

5.2.2 Operations. This section of the manual should include a general description of the repair

station operations. The manual should describe how the repair station operates, from

receiving an article for maintenance to approval for return to service. The description

could be in a narrative, flowchart, or other format. Any/all standard operating procedures

(SOP) developed for the facility could be included to aid in describing the repair station’s

normal, day-to-day business practices and/or operations.

5.2.3 Housing and Facilities. This section should include a description of the housing and

facilities. This also could be in a narrative, flowchart, or other format, such as a drawing

showing the floor plan of the facility. A drawing of the facility depicting the areas of

10/6/17 AC 145-9A

5-4

repair station operations is not regulatory, but can be helpful in describing the housing

and facilities. If using a drawing to further describe the areas of operation within the

repair station, the drawing could include the entrance(s), parking areas, and street

locations. The drawing and description may include the type of heating, lighting,

equipment location, shop areas, electrical, and compressed air outlets. A description of

any facilities used for spray painting, avionics, engine or airframe repair, or any other

work that would have special requirements should be included.

5.2.4 Equipment, Tools, and Materials.

5.2.4.1 The repair station must have the equipment, tools, and materials necessary to

perform the maintenance in accordance with part 43. The equipment, tools,

and materials must be located on the premises and under the repair station’s

control when the work is being done, per § 145.109. Some of this equipment

may be very expensive and the repair station may rarely use it. If the

repair station does not own the equipment and it is not kept at the facility, the

manual should describe how the equipment is obtained (e.g., lease, rental,

etc.). The manual should also describe the procedure for ensuring the

equipment is on the premises and under the repair station’s control at the time

the work is being performed.

5.2.4.2 This section of the manual should also describe where the equipment is likely

to be used and how the repair station will comply with special handling

requirements for sensitive tools and equipment. Some test benches and special

equipment may require calibration/verification after relocation. This section of

the manual should describe how the repair station ensures that required

calibration/verification is performed before using the equipment to perform

maintenance or alteration on civil aviation articles. The RSM should identify

which department is responsible for calibrating leased tools and equipment.

5.2.4.3 The RSM should include a description of the equipment used to perform

maintenance. For example, if the facility includes a machining area, then a

generic description of the types of machines located in that area should be

included in the manual. The description should not be so specific that

updating equipment would result in a manual revision. The equipment, tools,

and materials must be those recommended by the manufacturer of the article

or must be at least equivalent to those recommended by the manufacturer and

acceptable to the FAA. The repair station may refer to a list of equipment

maintained for other purposes, such as a list kept by the accounting

department for tax purposes.

5.2.5 Equivalent Tools and Equipment.

Note: This section is not intended to discuss industry standard tools and

equipment (e.g., wrenches, multimeters, sockets, etc.) that are manufactured to a

recognized industry standard.

10/6/17 AC 145-9A

5-5

5.2.5.1 If the repair station will be using equipment, tools, or materials other than

those recommended by the manufacturer, the manual should explain the

procedure it will use for determining equivalency of equipment, tools, and

materials. To determine equivalency, compare the technical requirements of

the special equipment or test apparatus recommended by the manufacturer

with the proposed replacements. The equipment or test apparatus may look

different, be made of different materials, be a different color, and so forth.

However, the equipment or test apparatus must be capable of performing all

necessary tests and checking all required parameters of the articles. The level

of accuracy should be at least equal to that recommended by the manufacturer

of the equipment/tools. Reverse engineering should include the data,

drawings, testing, or reports necessary to determine that the article is

equivalent to the article recommended by the manufacturer. The basis of

equivalency is the requirement that the article meet the manufacturer’s

standards and specifications in all respects regarding tolerances, repeatability,

and accuracy.

5.2.5.2 Standard industry practice establishes that each piece of special equipment or

test apparatus have a unique part number and serial number to identify it

within the repair station’s inventory system. Whether the equipment or

apparatus is obtained from the manufacturer or produced by the repair station,

it should be identified in the system for calibration and tracking purposes.

5.2.5.3 The following questions or concerns are offered as a guide and are intended to

help initiate the procedures for describing the housing, facilities, and

equipment in the manual(s). They should not be considered all-inclusive. Each

facility is unique and therefore may require additional procedures to verify

regulatory requirements and needs of the repair station.

1. Does the manual include a description of how the repair station

operates?

2. Does the manual include a description and/or a drawing of the

housing, identifying the various work facilities within the

building(s) and giving a narrative description of the housing and

facilities?

3. Does the description and/or layout identify areas with special

requirements?

4. Does the description include a generic overview of the type of

equipment?

5. When leasing or renting equipment, does the manual contain

procedures describing the lease/rent process and who is responsible

for managing the program, including the required

calibration/verifications?

6. How does the repair station ensure that the equipment is in place

and under the facility’s control when the work is performed?

10/6/17 AC 145-9A

5-6

7. If the repair station is using special equipment or tools other than

those recommended by the manufacturer, does the manual include

procedures for determining equivalency?

8. Does the manual include a description of the stock room/area, how

inventory is requisitioned for particular jobs, and how shelf life

inventory is maintained?

5.3 Capability List (CL).

5.3.1 References:

• Section 145.209(d).

• Section 145.215.

5.3.2 CL. A certificated repair station (CRS) with a limited rating may perform maintenance,

preventive maintenance, or alterations on an article if it is listed on a current CL

acceptable to the FAA or on the repair station’s operations specifications (OpSpecs). If

the repair station chooses to use a CL, the RSM must:

1. Contain procedures for revising the list and notifying the responsible Flight

Standards office;

2. Include how often the responsible Flight Standards office will be notified of

revisions;

3. Contain the procedures for the self-evaluation required under § 145.215(c) for

revising the CL;

4. Describe the methods and frequency of such evaluations; and

5. Contain the procedures for reporting the results to the appropriate manager for

review and action.

5.3.3 Revising the List. The CL itself may be included as a part of the RSM, but it is suggested

that it be made a separate document for ease in revising the list without the need to revise

the RSM; however, the procedures for performing the self-evaluation, revising the list,

and making those revisions available to the FAA must be included in the manual.

5.3.4 Self-Evaluation.

5.3.4.1 The individual performing the self-evaluation required under § 145.215(c)

should have the following qualifications:

1. Experience with performing evaluations (or audits, if that is the

method selected by the repair station).

2. An understanding of the requirements of part 145.

3. Knowledge of the maintenance requirements for the particular

make/model of the article to be added to the list.

10/6/17 AC 145-9A

5-7

5.3.4.2 The individual must follow the procedures in the RSM for accomplishing a

self-evaluation. Checklists, working documents, and forms designed by the

repair station to record the self-evaluation should be included in the forms

section of the manual system. The self-evaluation should ensure that the

repair station has the following:

1. The appropriate limited rating.

2. Adequate housing and facilities.

3. Recommended tools, equipment, and materials, or equivalent,

as necessary to perform the maintenance in accordance with

part 43.

4. Current technical data.

5. Sufficiently trained and qualified personnel.

6. Completed self-evaluation records on file.

5.3.5 Record and Report of Self-Evaluation Results. Procedures should be established for

conducting the self-evaluation, recording and retaining the self-evaluation, and reporting

the results to the appropriate repair station manager for review and action. The procedure

used to revise the list should describe the method used to indicate any changes made to

the list. Any deficiencies found during the self-evaluation should be corrected before the

article can be added to the CL. When the self-evaluation establishes satisfactory results,

the article may be placed on the CL. Notification of the revision to the list should be

provided to the responsible Flight Standards office in accordance with the procedures

required in § 145.209(d)(1). The repair station should retain documentation of the

self-evaluation as long as the article is listed on the current CL. If the article was

authorized in OpSpecs prior to establishing a CL, or the self-evaluation documents were

missing, a baseline assessment should be documented for the current listing. For

repair stations located outside the United States, the records of the self-evaluation may be

in the national language; however, they must be made available to the FAA in English.

5.3.6 Person Responsible for Maintaining the CL. The procedures for revising the CL and

notifying the responsible Flight Standards office should include who (by title) is

responsible for maintaining the CL and communicating any revisions to the office. If the

self-evaluation was satisfactory, the CL may be revised.

5.3.7 Maintaining the CL. CL currency can be shown by a List of Effective Pages (LEP) or

equivalent document. The CL must identify each article by make and model or other

nomenclature designated by the article’s manufacturer.

5.3.8 Revising the CL. If the repair station no longer wishes to maintain an article on its CL,

the article should be deleted. The repair station must have the necessary tools, equipment,

housing, facilities, and trained personnel to maintain articles on the CL at the time the

work is performed. The procedures in the manual should describe how to add and delete

articles from the list and how to forward the revised list to the FAA. The repair station

may choose to audit the CL on a regular basis to ensure that it continues to have the

10/6/17 AC 145-9A

5-8

housing, facilities, equipment, and technical data that meet all necessary requirements to

maintain the articles listed in the document. Whenever equipment, tooling, personnel, and

data must be obtained in order to perform the maintenance or alteration on an article that

is going to be added to the CL, the procedures for adding the article should state how the

repair station will ensure that the equipment, tooling, personnel, and data will be

available when the work is being performed on the article listed.

5.3.9 Electronic Media. If the CL is maintained on electronic media, the repair station will need

to work with the responsible Flight Standards office to ensure compatibility of the media,

equipment, and software with that of the office. Revision procedures will need to address

how the FAA will be notified of the revision.

5.3.10 Procedures Guide. The following questions or concerns are offered as a guide and are

intended to help initiate the procedures in the manual. They should not be considered

all-encompassing. Each facility is unique and therefore may require additional procedures

to verify regulatory requirements and the needs of the repair station.

1. Who (by title) will maintain the CL?

2. How will the self-evaluation be performed?

3. Who (by title) will perform the self-evaluation?

4. How will the self-evaluation be documented?

5. How will results of the self-evaluation be reported to management and how

will management review the addition of capabilities to the list?

6. How will items be added to and deleted from the list?

7. How are changes clearly indicated on the document?

8. If electronic media is used, is the hardware and software compatible with that

of the responsible Flight Standards office?

9. Where and by whom will self-evaluation reports be maintained?

10. Are the self-evaluations retained by the repair station for as long as an article

is listed on the current CL and what is the time period of retention after an

article is removed?

5.4 Training Program Revision.

5.4.1 References:

• Section 145.163.

• Section 145.209.

5.4.2 Chapter Information. Repair stations developing a training program may use the

information in this chapter as a reference. AC 145-10, Repair Station Training Programs,

provides additional information on developing the repair station employee training

program required under § 145.163.

10/6/17 AC 145-9A

5-9

5.4.3 Required Procedures. The RSM must include procedures required by § 145.163 for

revising the training program. It must also include procedures for submitting those

revisions to the responsible Flight Standards office for approval.

5.4.4 Responsibility for Revisions. The procedures should address who (by title) will be

responsible for ensuring that revisions are submitted to the principal inspector (PI) at the

responsible Flight Standards office for review and approval.

5.4.5 Frequency of Review. The procedures should address how often the program will be

reviewed to determine if it is current and adequate for the type of maintenance being

performed at the facility. Because the advancements in technology can cause aviation

maintenance to change rapidly, a periodic review of training needs would be appropriate.

Repair stations that have established a management review program should include the

training program for review during that meeting.

5.4.6 Training Program. The training program may be documented as a section of the RSM or

as a separate document within the manual system. If the training program is a separate

document, that document will need to include the procedures for submission to the FAA

for approval prior to implementing the training.

5.4.7 Training Program Guide. The following questions or concerns are offered as a guide and

are intended to help the repair station initiate the procedures in its manual(s). They should

not be considered all-inclusive. Each facility is unique and may require additional

procedures to verify regulatory requirements and the needs of the repair station.

1. Who (by title) is responsible for submitting the initial training program and its

revisions to the FAA?

2. When will the revision be submitted?

3. What are the procedures for submitting revisions to the responsible Flight

Standards office for approval?

4. How often will the training program be reviewed for currency and

completeness?

5. Who (by title) is responsible for performing the review?

6. How will revisions be recorded and implemented?

7. How will the revised text be identified?

5.5 Work Performed at Another Location.

5.5.1 Reference. Section 145.203.

5.5.2 Special Circumstances: § 145.203(a) (OpSpec D100 is not required). This section states

that a repair station may temporarily transport material, equipment, and personnel needed

to perform maintenance, preventive maintenance, alterations, or certain specialized

services on an article for which it is rated to a place other than the repair station’s fixed

locations due to a special circumstance, as determined by the FAA. Examples would be

10/6/17 AC 145-9A

5-10

an aircraft on the ground or in preparation for a ferry flight (nonroutine maintenance or

alteration actions).

Note: Normally, work performed at another location does not include working

outside the country where the repair station is located. However, work performed

outside the country under a special circumstance may be authorized under

§ 145.203(a). If work must be performed outside the country, the repair station

should obtain required approvals from the country where the work will be

performed and notify their responsible Flight Standards office.

5.5.2.1 If the repair station wishes to perform maintenance away from the fixed

location for special circumstances, it may put a procedure in its manual for the

types of special circumstances that it may need to perform. The RSM should

address the following:

1. The types of and limitations on the work that would be considered

special circumstances (e.g., emergency repairs, aircraft on the

ground, and ferry flight preparation).

2. The estimated length of time away from the fixed location.

3. The procedure to ensure adequate personnel are chosen, including

the person(s) responsible for performing, supervising, inspecting

(including inspections regarding receiving/incoming, preliminary,

hidden damage, in-process, and final), and approving the work for

return to service.

4. If necessary, the procedure for ensuring the location will have the

necessary housing and facilities for accomplishing the work.

5. The procedure for transporting any equipment, tools, materials,

and data to the work site. If the equipment, tools, materials, and/or

data will be obtained at the location, include the procedure used for

ensuring they are received and controlled under the repair station’s

quality system for the duration of their work.

6. The procedures used for storing any equipment, tools, materials,

and data for the duration of the project.

7. The procedure used in notifying the responsible Flight Standards

office of the request to work away and what type of information

will be included in the request. Examples of information could

include identifying the customer and describing the work requested

or anticipated, and the location at which the work will be

performed.

10/6/17 AC 145-9A

5-11

8. The title of the person who will notify the responsible Flight

Standards office of the special circumstance and how that

notification will be made.

9. How the repair station will receive the FAA’s determination of

acceptance or denial for the request to work away from the fixed

location for the special circumstance.

5.5.2.2 By requesting the general determination of special circumstances and

obtaining verification from the FAA (written response), the repair station

will not need to request permission on a case-by-case basis. The repair station

would follow its procedures and notify the FAA each time work was

performed away from the fixed location for those special circumstances.

5.5.2.3 If the repair station will not perform work away from location on a recurring

basis and does not include a procedure in its manual for work away from the

fixed location for special circumstances, then it must submit each request to

the FAA for evaluation on a case-by-case basis prior to performing the

requested work. The FAA will make a determination and inform the repair

station of any parameters that it must follow to perform the requested work.

The request should provide the following information:

1. The types of and limitations on the work that would be considered

special circumstances (e.g., aircraft on the ground, ferry flight

preparation, maintenance that must be performed prior to moving

an article due to an unsafe condition, etc.).

2. The estimated length of time away from the fixed location.

3. The procedure used to ensure the location will have the necessary

housing and facilities for accomplishing the work when necessary.

4. The procedure used for transporting any equipment, tools,

materials, and data to the work site. If the equipment, tools,

materials, and/or data will be obtained at the location, include the

method for ensuring they are received and controlled under the

repair station’s quality system for the duration of their use on the

project.

5. The procedure used for storing any equipment, tools, materials,

and data for the duration of the project.

6. The FAA will make a determination and provide a written

response to the repair station, which may include additional

parameters or limitations that it must follow to ensure compliance

with parts 43 and 145.

5.5.3 Recurring Work: § 145.203(b) (OpSpec D100 is required). If the repair station is